2025 Guide: How to Choose the Right Tumble Blasting Machine for Your Needs

When it comes to surface preparation and cleaning in various industrial applications, selecting the right equipment is crucial for achieving optimal results. A Tumble Blasting Machine is an effective solution that utilizes abrasive materials to clean, deburr, or finish workpieces with precision and efficiency. As technology advances and manufacturing processes evolve, understanding the specific requirements of your operations is essential to make an informed choice in 2025.

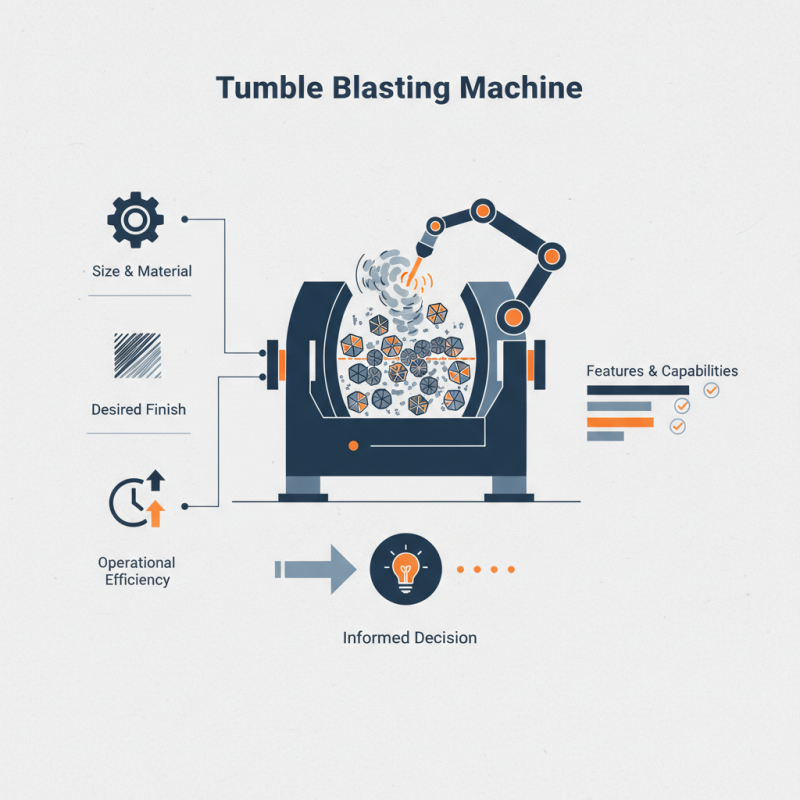

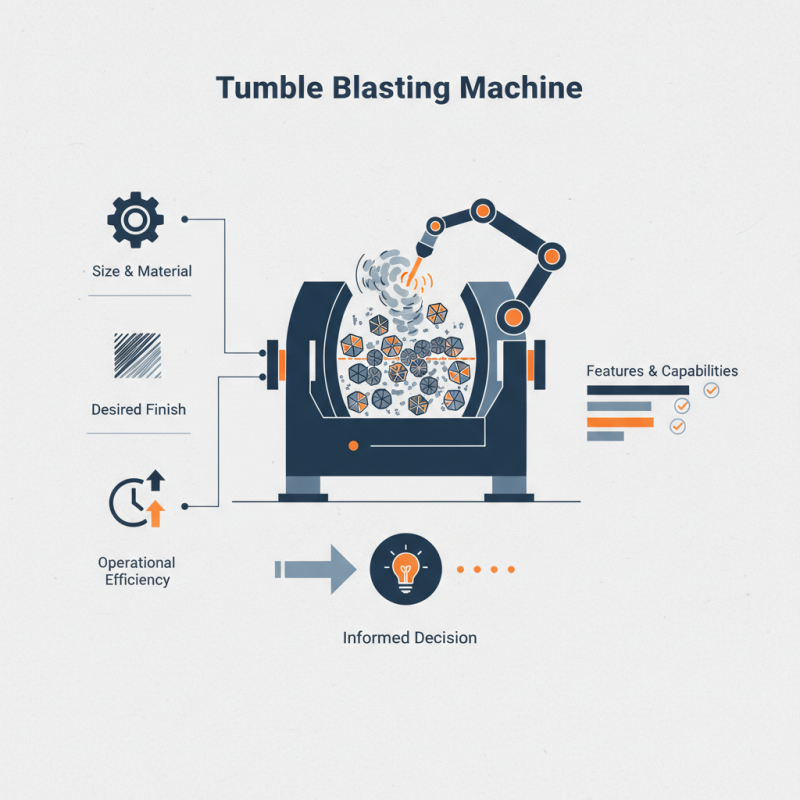

Choosing the appropriate Tumble Blasting Machine involves careful consideration of several factors, including the size and material of the items being processed, the desired surface finish, and operational efficiency. With an array of machines available, each designed with different features and capabilities, it can be daunting to determine which model aligns best with your needs. This guide aims to provide valuable insights into the key aspects to evaluate, ensuring that you find the ideal Tumble Blasting Machine to enhance your production workflow.

By taking the time to analyze your requirements and the functionalities of available machines, you can make a well-informed decision that not only boosts productivity but also optimizes quality. In the following sections, we will explore the critical considerations and features to look for in a Tumble Blasting Machine, empowering you to select the right model tailored to your specific applications.

Understanding Tumble Blasting Machines and Their Applications

Tumble blasting machines are highly versatile tools used to treat and clean a variety of surfaces, making them essential in industries such as automotive, aerospace, and manufacturing. These machines utilize a unique process that propels abrasive materials onto surfaces, effectively removing rust, paint, and other contaminants. According to a report by MarketsandMarkets, the global shot blasting market is expected to grow from USD 4.7 billion in 2020 to USD 6.3 billion by 2025, highlighting the increasing demand for effective surface preparation solutions. Understanding the specific applications of tumble blasting machines can help businesses select the right type for their needs, whether for large-scale component finishing or smaller-scale processing.

When considering a tumble blasting machine, it's vital to evaluate its capacity based on your production volume. For instance, a machine designed for high throughput may be necessary for large manufacturing facilities, while smaller operations might benefit from compact models. Additionally, the choice of abrasive material is crucial. Utilizing the wrong abrasive can lead to subpar results and increased wear on the equipment.

**Tips:** Always assess the compatibility of the machine with the materials you intend to process. It may also be beneficial to consult with industry experts to determine the best machine specifications that align with your operational needs. Regular maintenance practices are essential to ensure the longevity and efficiency of the machines, so create a maintenance schedule tailored to your usage patterns.

2025 Guide: How to Choose the Right Tumble Blasting Machine for Your Needs

This bar chart illustrates the typical specifications of tumble blasting machines in 2025, including capacity, power consumption, air consumption, cost, and maintenance frequency.

Key Factors to Consider When Choosing a Tumble Blasting Machine

When selecting the right tumble blasting machine, there are several key factors that you should consider to ensure it meets your specific needs. First, evaluate the size and shape of the parts you will be processing. A machine that accommodates various sizes may be more advantageous, allowing you to handle different projects without requiring multiple units. Additionally, consider the material of the components being blasted; certain machines are better suited for specific materials, which can impact the finish quality and the longevity of the equipment.

Another crucial aspect to examine is the machine's capacity and efficiency. Look into the blast cycle times, as faster machines can significantly enhance productivity. Furthermore, assess the ease of operation and maintenance. A machine that is simple to operate and maintain can save time and reduce operational costs. Always consider energy consumption and the environmental impact of the equipment, as these factors can affect both your budget and your ecological footprint.

Tips: Before finalizing your choice, it may be beneficial to seek feedback from other users or operators. Understand their experiences regarding machine performance and reliability. Additionally, ensure that the machine complies with current safety and operational standards to avoid any future complications.

Types of Tumble Blasting Machines: Which One is Right for You?

When choosing a tumble blasting machine, understanding the different types available is crucial to making the right decision for your specific requirements. The primary types include batch-type machines, continuous flow machines, and automation-centric models. Batch-type machines are ideal for small to medium volumes of parts, providing flexibility and lower initial investment. Continuous flow machines, on the other hand, are designed for high-volume operations, offering efficiency and consistent results. Automation-centric models incorporate advanced technology to optimize processes and reduce labor costs. According to industry reports, the global tumble blasting machine market is expected to grow at a CAGR of 5.6% by 2026, indicating an increasing demand for diverse blasting solutions.

When selecting the appropriate machine, consider factors such as the size and type of components you will be treating, the material being blasted, and the desired finish quality. A tip for better decision-making is to conduct a thorough assessment of your production needs and consult with industry experts. This groundwork can help clarify whether a batch-type or continuous flow model aligns better with your operational demands. Additionally, investing in a machine equipped with adjustable settings can provide the versatility to handle various materials and finishes efficiently.

Remember that the efficiency and performance of a tumble blasting machine can also greatly depend on the quality of the abrasives used. Always choose high-quality abrasives suited for your specific application to maintain optimal performance levels and extend the lifespan of your equipment.

2025 Guide: How to Choose the Right Tumble Blasting Machine for Your Needs

| Machine Type |

Best For |

Capacity (kg) |

Cleaning Media |

Price Range ($) |

| Horizontal Tumble Blaster |

Small to Medium Parts |

100 - 500 |

Steel Shot |

2500 - 5000 |

| Vertical Tumble Blaster |

Large Components |

500 - 2000 |

Aluminum Oxide |

4000 - 8000 |

| Batch Tumble Blaster |

Mixed Part Sizes |

50 - 300 |

Glass Beads |

1500 - 3500 |

| Continuous Tumble Blaster |

High Volume Production |

1000 - 5000 |

Ceramic Media |

6000 - 12000 |

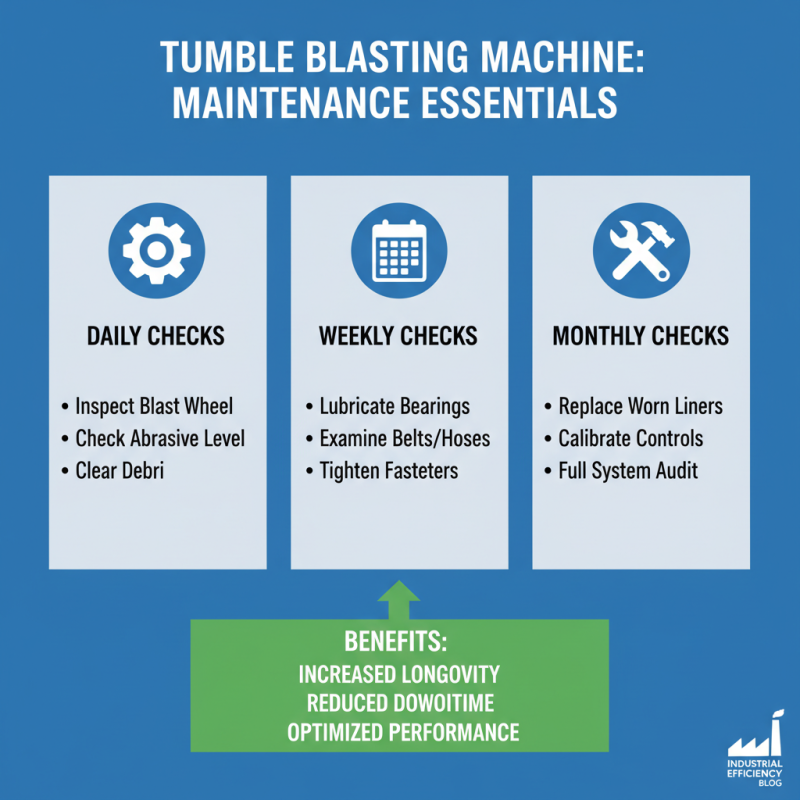

Maintenance and Operational Considerations for Tumble Blasting Machines

When selecting a tumble blasting machine, understanding the maintenance and operational considerations is essential to ensure longevity and efficiency. Regular maintenance tasks should include checking and replacing worn-out components such as belts, bearings, and blast wheels. A well-maintained machine not only enhances performance but also minimizes downtime and repair costs. Establishing a routine maintenance schedule, including daily, weekly, and monthly checks, can help identify potential issues before they lead to significant operational disruptions.

Operational considerations are equally important. Operators should be trained not only on how to use the machine effectively but also on how to monitor its performance. Keeping an eye on blast pressure, media consumption, and wear rate can provide valuable insights into the machine’s condition. Additionally, ensuring correct media type and size according to the specific cleaning or finishing requirements can reduce wear on the system and improve the quality of the output. Awareness of the machine's operating environment, including ventilation and dust management, can further enhance the overall safety and efficiency of tumble blasting operations.

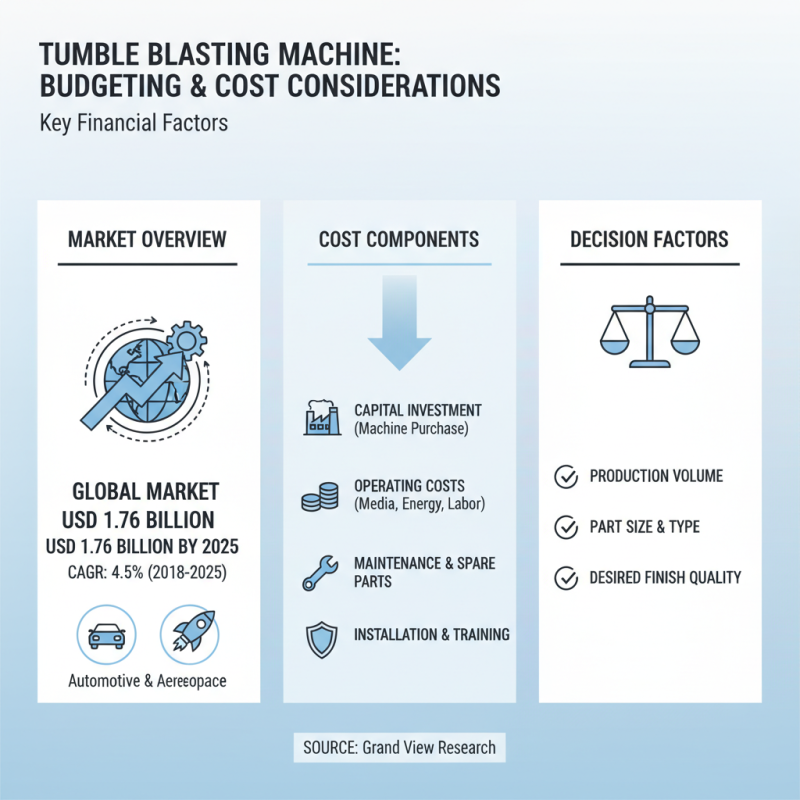

Budgeting: Cost Considerations for Purchasing a Tumble Blasting Machine

When considering the purchase of a tumble blasting machine, budgeting and cost considerations play a crucial role in the decision-making process. According to a recent industry report by Grand View Research, the global market for blasting machines is projected to reach USD 1.76 billion by 2025, with an expected compound annual growth rate (CAGR) of 4.5%. This growth reflects the increasing demand for surface treatment and the rising need for effective cleaning solutions across various sectors, including automotive and aerospace.

When estimating the total cost of acquiring a tumble blasting machine, buyers should take into account not only the initial purchase price but also operational expenses such as maintenance, energy consumption, and the cost of replacement materials. Research from Market Research Future highlights that operational costs can account for up to 30% of the total expenditure over the lifespan of the machine. Therefore, it's prudent for businesses to analyze their specific needs and choose a machine that balances upfront investment with long-term efficiency. By prioritizing these factors, companies can ensure they are making a sound financial decision in their purchase.

Home

Equipment

Vacuum Process Casting Molding Line

Automatic Flaskless Sand Molding Production Line

Sand Preparation Automation Line

Shot Blasting Peening Equipment

Stainless Steel Stripe Shot Blasting Machine

Steel Preservation Line

Roller Conveyor Shot Blasting Machine

Hook Type Shot Blasting Machine

Pass Through Monorail Shot Blasting Machine

Mesh Belt Shot Blasting Machine

Rotary Table Shot Blasting Machine

Trolley Type Shot Blasting Machine

Steel Pipe Shot Blasting Machine

Crawler Type Shot Blasting Machine

Rolling Drum Shot Blasting Machine

Automatic Titling Drum Shot Blasting Machine

Portable Shot Blasting Machine

Abrasive Blast Booth And Spray Paint Booth

Enviromental Dust Removal Equipment

Why Xinke

News Room

Blog

Contact Us