Top 2025 Rotary Shot Blasting Machine Trends You Need to Know

The rotary shot blasting machine has emerged as a pivotal element in various industrial applications, particularly in surface preparation and cleaning processes. Recent market analyses indicate that the global shot blasting equipment market is projected to reach USD 400 million by 2025, growing at a CAGR of 4.6%. This growth is driven by the increasing demand for efficient surface finishing across multiple sectors, including aerospace, automotive, and heavy machinery. The integration of advanced technologies, such as automation and digital monitoring systems, is enhancing the capabilities of rotary shot blasting machines, making them vital for achieving higher efficiency and precision.

As industries strive to meet stringent quality standards, the evolution of rotary shot blasting machines is marked by significant trends that emphasize sustainability and operational efficiency. Reports indicate a rising preference for eco-friendly blasting materials and techniques that minimize waste and reduce environmental impact. Furthermore, advancements in machine design are enabling operators to achieve faster processing times and improved surface quality. The adoption of smart technologies for predictive maintenance and performance monitoring is also reshaping the landscape, allowing companies to optimize their operations and reduce downtime. Understanding these trends is essential for businesses aiming to leverage rotary shot blasting machines effectively in their manufacturing processes.

Top Advancements in Rotary Shot Blasting Technology for 2025

The advancements in rotary shot blasting technology are ushering in a new era of efficiency and precision for 2025. One of the most notable trends is the integration of automation and smart technology into shot blasting systems. With the introduction of IoT-enabled machines, operators can monitor and control the blasting process remotely, optimizing productivity and minimizing downtime. These machines can analyze performance data in real-time, allowing for immediate adjustments to blasting parameters, thereby enhancing overall effectiveness and reducing material wastage.

Additionally, there is a growing emphasis on environmental sustainability within the rotary shot blasting sector. New technologies are being developed that significantly reduce dust emissions and improve the recovery and reuse of abrasive materials. Advanced filtration systems are now capable of capturing and recycling the vast majority of particles generated during the blasting process, ensuring compliance with stricter environmental regulations and promoting a cleaner workspace. As companies prioritize sustainability, innovations in rotary shot blasting technology are making significant strides towards greener manufacturing practices, benefiting both the industry and the environment.

Key Market Drivers and Growth Projections for Shot Blasting Machines

The global shot blasting machine market is witnessing significant growth, driven by various key factors. According to a report by Research and Markets, the market is projected to expand at a compound annual growth rate (CAGR) of approximately 6.5% from 2023 to 2030. One of the primary drivers of this growth is the increasing demand for surface preparation in industries such as automotive, aerospace, and construction. As these sectors advance toward automation and increased operational efficiency, the need for reliable and high-quality surface finishing solutions has become paramount.

Additionally, the ongoing trend of industrialization in emerging economies is contributing to the rising adoption of shot blasting machines. The market's expansion is further supported by technological advancements that enhance machine performance and productivity. Innovations such as the integration of digital controls and improved dust collection systems not only meet stringent environmental regulations but also optimize energy consumption, making operations more cost-effective.

Data from the Global Blasting Equipment Market Report indicates that the Asia-Pacific region, particularly countries like China and India, is expected to dominate the market due to rapid industrial growth and infrastructure development projects in these nations.

Innovative Materials Enhancing Shot Blasting Efficiency in 2025

In 2025, the shot blasting industry is poised for significant advancements driven by innovative materials that enhance efficiency and effectiveness in various applications. Recent studies indicate that the global shot blasting machine market is expected to grow at a CAGR of around 4.5% from 2023 to 2028, underscoring the increasing demand for efficient surface treatment solutions. A pivotal focus has been on the adoption of high-performance abrasives made from advanced composites, which provide improved durability and cost-efficiency.

Reports suggest that the market for advanced abrasive materials is anticipated to reach USD 1.1 billion by 2025, highlighting a clear shift towards materials that optimize performance while reducing waste.

Moreover, the integration of eco-friendly alternatives in shot blasting processes is gaining traction. The use of recycled materials, such as steel shots made from repurposed waste, is becoming more prevalent as industries seek sustainable practices. A study published in the Journal of Cleaner Production states that adopting recycled abrasives can reduce material costs by up to 30% while also lowering environmental impact. Additionally, new technologies that facilitate the use of ceramic and glass beads are being developed, enhancing the precision and surface quality achieved in treatments. As these innovative materials emerge, the shot blasting sector is set to embrace a future defined by sustainability and efficiency.

Impact of Automation and AI on Rotary Shot Blasting Operations

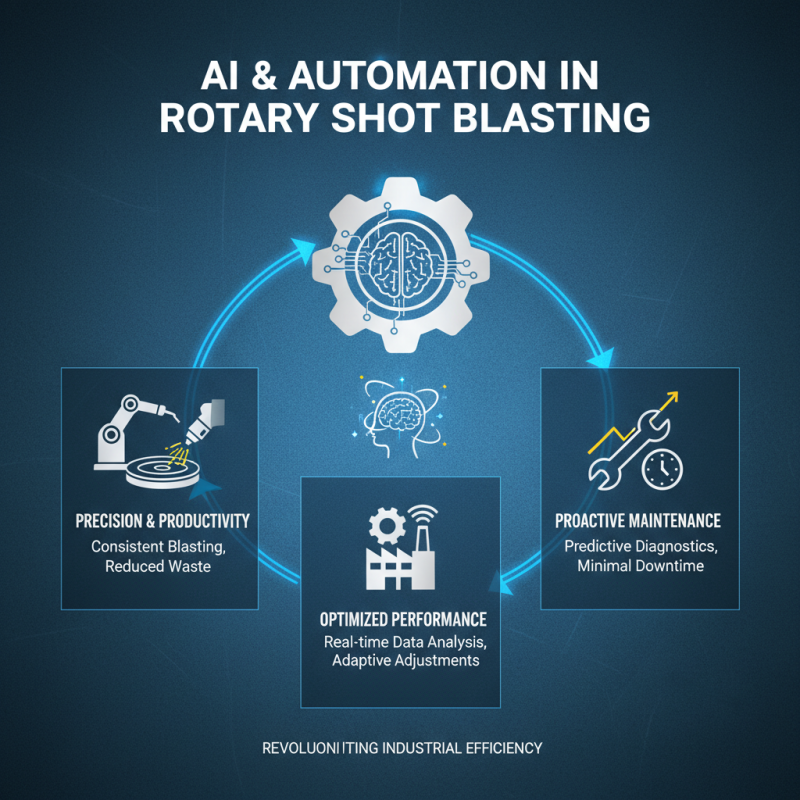

The integration of automation and artificial intelligence (AI) into rotary shot blasting operations is revolutionizing the industry. Advanced automation allows for more precise and consistent blasting processes, which significantly enhances productivity and reduces material wastage. AI-driven systems can analyze data in real time to optimize performance, adjust parameters on the fly, and even predict maintenance needs before issues arise. This proactive approach not only prolongs equipment lifespan but also minimizes downtime, leading to greater operational efficiency.

Tips for implementing automation in rotary shot blasting include starting with a thorough assessment of current processes to identify bottlenecks and areas for improvement. Investing in training for your workforce on the new technologies ensures a smooth transition and maximizes the potential of automated systems. Additionally, consider gradual integration—begin with less critical operations before fully committing to large-scale automation.

As AI continues to evolve, its impact on rotary shot blasting will likely grow, enhancing safety and quality control. Smart systems can provide valuable insights by continuously monitoring the blasting environment and adjusting parameters based on external factors like humidity or temperature. Keeping abreast of these trends will be crucial for companies looking to stay competitive in this rapidly changing landscape.

Sustainability Trends and Eco-Friendly Practices in Shot Blasting Industry

The shot blasting industry is undergoing a significant transformation as sustainability trends and eco-friendly practices become essential in manufacturing processes. According to a report by ResearchAndMarkets, the global shot blasting market is projected to reach $10.12 billion by 2025, with a notable emphasis on eco-friendly equipment. As companies strive to reduce their carbon footprint, innovations such as the use of recyclable materials for shot media and energy-efficient blasting systems are gaining traction.

One prominent trend is the adoption of dry blasting techniques that minimize waste and water use. Unlike traditional methods, dry blasting systems utilize less water, which not only conserves this precious resource but also reduces the energy required for heating water. Furthermore, using recycled materials for abrasive media helps in minimizing environmental impact, aligning with circular economy principles. It’s encouraging to see companies aiming for zero waste production through these initiatives, as mandated by local and international regulations aimed at promoting greener practices.

Tip: To enhance sustainability in your shot blasting operations, consider integrating a recycling system for your abrasive media. This can significantly reduce operational costs and limit the environmental impact associated with production waste. Additionally, training your team on eco-friendly practices can foster a culture of sustainability within your organization, leading to long-term benefits for both the environment and your business.

Top 2025 Rotary Shot Blasting Machine Trends You Need to Know - Sustainability Trends and Eco-Friendly Practices in Shot Blasting Industry

| Trend |

Description |

Impact on Sustainability |

Adoption Rate (%) |

| Recyclable Abrasives |

Increasing use of materials that can be reused or recycled. |

Reduces waste and conserves resources. |

70% |

| Dust Suppression Technologies |

Innovative systems to minimize dust emissions during blasting. |

Improves air quality and worker safety. |

65% |

| Energy-efficient Machines |

Equipment designed to consume less energy while maintaining performance. |

Decreases carbon footprint and operating costs. |

80% |

| Automation and IoT |

Integration of smart technology for better efficiency and monitoring. |

Facilitates optimal resource use and reduces waste. |

50% |

| Eco-friendly Paint Removal |

Methods that utilize biodegradable chemicals for paint stripping. |

Reduces environmental impact compared to traditional methods. |

60% |

Home

Equipment

Vacuum Process Casting Molding Line

Automatic Flaskless Sand Molding Production Line

Sand Preparation Automation Line

Shot Blasting Peening Equipment

Stainless Steel Stripe Shot Blasting Machine

Steel Preservation Line

Roller Conveyor Shot Blasting Machine

Hook Type Shot Blasting Machine

Pass Through Monorail Shot Blasting Machine

Mesh Belt Shot Blasting Machine

Rotary Table Shot Blasting Machine

Trolley Type Shot Blasting Machine

Steel Pipe Shot Blasting Machine

Crawler Type Shot Blasting Machine

Rolling Drum Shot Blasting Machine

Automatic Titling Drum Shot Blasting Machine

Portable Shot Blasting Machine

Abrasive Blast Booth And Spray Paint Booth

Enviromental Dust Removal Equipment

Why Xinke

News Room

Blog

Contact Us