2026 Best Sandblasting Equipment for Every Professional Needs?

The demand for high-quality Sandblasting Equipment has surged in recent years. According to industry reports, the global sandblasting market is projected to grow significantly, reaching over $5 billion by 2026. This expansion reflects the increasing applications of sandblasting in industries such as automotive, construction, and aerospace.

Professionals require equipment that meets their specific needs. From portable units for small jobs to large-scale systems for industrial use, the choices are vast. However, not all equipment delivers the promised results. Many users report issues such as uneven finishes or excessive wear on components. These challenges highlight the importance of selecting the right sandblasting equipment for optimal performance.

Investing in quality equipment is crucial. It not only improves efficiency but also enhances the quality of work. As the market evolves, staying informed about the latest technology advancements is essential. Understanding the limitations and potential of sandblasting tools will guide professionals in making better decisions. Yet, even the best equipment will require user knowledge and experience to achieve ideal outcomes.

2026 Trends in Sandblasting Equipment: An Industry Overview

In 2026, the sandblasting industry continues to evolve rapidly. Technological advancements are reshaping how professionals approach surface preparation. Equipment is becoming more efficient, yet users still face challenges. Many are looking for machines that balance power and portability.

One noticeable trend is the increased focus on eco-friendly media. Traditional materials are being replaced by sustainable options. This shift is essential for meeting regulatory standards and reducing environmental impact. However, some professionals find it difficult to adapt to these new materials. The effectiveness may vary, leading to mixed results on different surfaces.

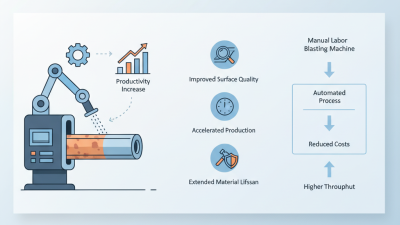

Another interesting development is the rise of automation in sandblasting equipment. Automated machines minimize human error and improve consistency. Yet, some operators express concerns about losing manual skills. Striking a balance between automation and traditional techniques is vital. The industry must address these needs as it moves forward.

2026 Trends in Sandblasting Equipment

This bar chart illustrates the projected market demand for various types of sandblasting equipment in 2026. As the industry evolves, equipment such as portable sandblasters and blast cabinets are anticipated to be in high demand, reflecting trends in professional needs.

Key Features to Consider in Sandblasting Equipment for Professionals

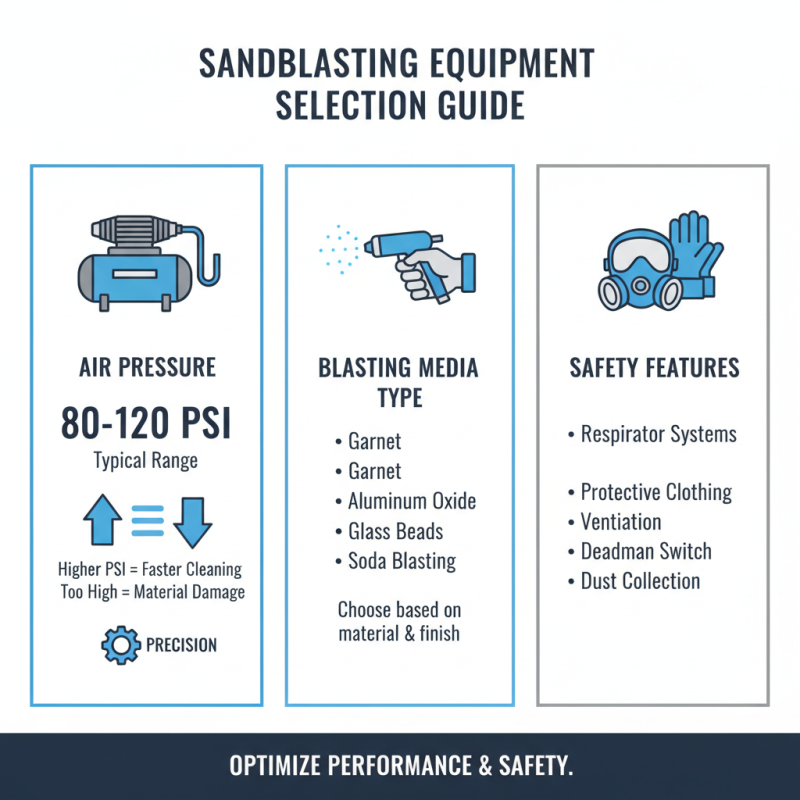

When selecting sandblasting equipment, professionals should prioritize several key features. Air pressure is crucial. A range between 80 to 120 PSI is typical. Higher pressures can enhance efficiency and speed up the blasting process. But, excessive pressure can lead to material damage. Precision is key here.

Material compatibility matters too. Different jobs require different abrasives. For instance, aluminum oxide is ideal for harder surfaces, while glass beads are suited for softer materials. The wrong choice can result in poor outcomes. Flexibility in nozzle size also helps. It allows professionals to adjust to various tasks, ensuring versatility and effectiveness.

Safety features cannot be overlooked. Protective gear and proper ventilation systems are essential. Reports indicate that over 4,000 workers suffer injuries annually due to inadequate safety measures. Investing in quality equipment and training is critical. Understanding the operational limits of the chosen tools is vital for long-term success. Balancing quality with cost is often a challenge. Every professional should regularly reassess their equipment to maximize productivity and safety.

Top Sandblasting Equipment Brands: Analyzing Market Leaders in 2026

In 2026, the sandblasting equipment market is filled with a variety of brands. It’s essential to understand the key players that dominate the industry. Leading brands often showcase high durability and efficiency. However, not all options fit every professional need. A discerning user must assess features carefully.

Some brands stand out due to innovative technology. These tools can enhance productivity and reduce material waste. Yet, there may be a steep learning curve for new users. It's crucial to find a balance between sophistication and usability. Also, considering maintenance costs is vital. A powerful machine might require frequent upkeep, impacting overall efficiency.

Professionals should also evaluate customer support services. Often, brands with better support tend to foster long-term relationships. User feedback plays a critical role in this. Users frequently indicate their frustrations with limited warranties. Brands that address these concerns typically gain loyal customers. Understanding this dynamic is key for navigating the market effectively.

2026 Best Sandblasting Equipment for Every Professional Needs

| Equipment Type |

Power Source |

Max Pressure (psi) |

Abrasive Flow Rate (lbs/min) |

Weight (lbs) |

Price Range ($) |

| Portable Sandblaster |

Electric |

90 |

8 |

35 |

150 - 300 |

| Blast Cabinet |

Pneumatic |

100 |

12 |

300 |

500 - 800 |

| Stationary Sandblaster |

Diesel |

120 |

15 |

450 |

900 - 1200 |

| Automatic Sandblaster |

Electric |

150 |

20 |

600 |

2000 - 4000 |

| Suction Sandblaster |

Compressed Air |

80 |

6 |

30 |

100 - 200 |

Cost Analysis of Sandblasting Equipment: What Professionals Should Expect

In the sandblasting industry, costs can vary significantly based on equipment and usage. A recent industry report indicates that average costs for sandblasting equipment can range from $1,500 to $10,000. The price often includes compressors, hoses, and protective gear. Professionals must consider these aspects when budgeting for a project.

Maintenance is another factor that affects overall costs. Regular upkeep can save money in the long run. Neglecting equipment may lead to more significant issues. In fact, many professionals report spending up to 20% of their equipment costs on repairs annually. This statistic highlights the need for diligent care and inspection.

Training costs should not be overlooked. Investing in proper training or certification can seem expensive. However, professionals can reduce mistakes and improve efficiency. Some studies suggest that businesses with well-trained staff see a 30% increase in productivity. This further emphasizes the overall value of considering expenses beyond just equipment purchase alone.

Home

Equipment

Vacuum Process Casting Molding Line

Automatic Flaskless Sand Molding Production Line

Sand Preparation Automation Line

Shot Blasting Peening Equipment

Stainless Steel Stripe Shot Blasting Machine

Steel Preservation Line

Roller Conveyor Shot Blasting Machine

Hook Type Shot Blasting Machine

Pass Through Monorail Shot Blasting Machine

Mesh Belt Shot Blasting Machine

Rotary Table Shot Blasting Machine

Trolley Type Shot Blasting Machine

Steel Pipe Shot Blasting Machine

Crawler Type Shot Blasting Machine

Rolling Drum Shot Blasting Machine

Automatic Titling Drum Shot Blasting Machine

Portable Shot Blasting Machine

Abrasive Blast Booth And Spray Paint Booth

Enviromental Dust Removal Equipment

Why Xinke

News Room

Blog

Contact Us