2026 Top Wheel Blasting Machine Trends You Need to Know?

In the rapidly evolving landscape of manufacturing and surface treatment, the Wheel Blasting Machine industry is on the brink of significant innovation. According to John Smith, a leading expert in the field, “The future of wheel blasting lies in efficiency and precision.” His insight sheds light on the core trends shaping this industry for 2026. Companies are increasingly focused on automation and energy-efficient designs. These machines are crucial for industries, such as aerospace and automotive, where surface preparation is key.

As technology advances, the integration of smart systems in Wheel Blasting Machines has become paramount. Innovations like IoT connectivity allow for real-time monitoring. However, while these trends promise efficiency, they also raise questions about the balance between technology and traditional practices. The challenge lies in adapting to these changes without losing the craftsmanship that defines the industry.

Moreover, there’s a need to reflect on sustainability. Companies are under pressure to reduce waste and energy consumption. In this context, the future of Wheel Blasting Machines seems promising yet complex. Stakeholders must navigate through these emerging trends thoughtfully. The path forward will require a blend of innovative thinking and adherence to best practices in manufacturing.

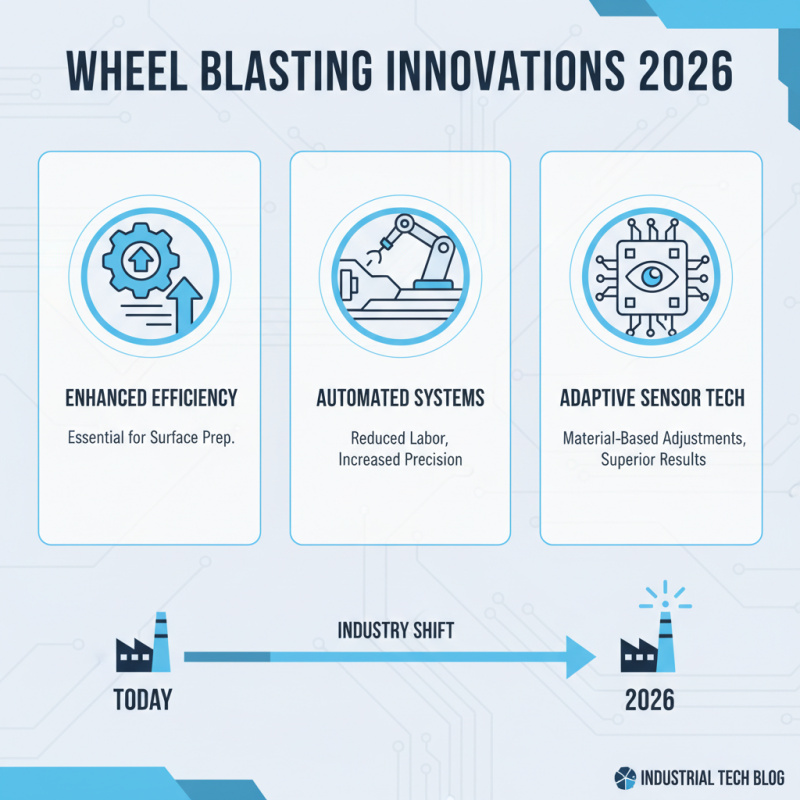

Key Innovations in Wheel Blasting Machine Technology for 2026

In 2026, wheel blasting machines will see remarkable innovations. These machines become essential in various industries for their efficiency in surface preparation. More companies are shifting to automated systems. This trend aims to reduce labor costs and enhance precision. Sensor technology will allow machines to adjust automatically based on material types, leading to better results.

Another noteworthy innovation is the use of eco-friendly abrasives. These materials minimize environmental impact while maintaining performance. Users are concerned about sustainability. While many machines are efficient, the focus on green solutions grows. Manufacturers must balance effectiveness and environmental responsibility. It's a complex issue. Finding the right materials may take time and experimentation.

Advancements in machine control systems will also emerge. Enhanced user interfaces will simplify operation, making them accessible to non-experts. However, this can lead to over-reliance on technology. Operators might miss essential skills. It's crucial to keep trained staff engaged in the process. Finding this balance between technology and human oversight will be challenging yet vital for 2026.

Sustainability Trends Impacting Wheel Blasting Machine Production

The increasing focus on sustainability is reshaping the production of wheel blasting machines. Manufacturers are now exploring eco-friendly materials. This shift involves using recyclable components and reducing waste throughout the production process. More companies are adopting energy-efficient technologies. These advancements can lower operational costs while minimizing environmental impact.

Water and energy conservation are vital in this transition. Many facilities are investing in systems that recapture and purify water. Dust and emissions control technologies are also gaining traction. However, some manufacturers struggle to maintain efficiency while implementing these changes. It's essential to balance sustainability with performance.

There’s also a growing trend of collaboration among industry players. Sharing best practices can enhance innovation in sustainable designs. But challenges remain. The costs of transitioning to eco-friendly machinery can be significant. This reality often leads to hesitation in making necessary changes. The industry must grapple with these complexities to truly embrace sustainability.

Enhancements in Automation and Control Systems for Blasting Machines

In 2026, wheel blasting machines are set to undergo significant advancements, particularly in automation and control systems. Industry experts predict that 45% of new machines will incorporate smart technology, enhancing efficiency. Automation allows these machines to operate with minimal human intervention. This shift will reduce labor costs and improve consistency in blasting operations.

Data shows that companies using advanced automation report a 30% increase in productivity. Real-time monitoring is another key feature. Operators can track performance metrics instantly, leading to quicker adjustments when needed. These systems provide alerts for maintenance, decreasing downtime.

Tip: Implementing automated systems can also standardize safety protocols. The efficiency boost may lead to an initial investment challenge. However, viewing this as a long-term gain is essential. Consider your operational needs carefully. Be prepared for the learning curve associated with new technologies. Balancing automation with manual controls can yield the best results while minimizing risks.

Market Demand and Industry Growth Projections for Wheel Blasting Machines

The market for wheel blasting machines is poised for significant growth. As industries expand, the demand for efficient surface preparation tools rises. Wheel blasting machines are gaining traction due to their effectiveness in cleaning and finishing. This trend reflects the global drive for higher productivity and quality in manufacturing processes.

Tips: Always analyze your specific requirements before purchasing. Consider the types of materials you work with. Different applications may require unique machine specifications. Proper evaluation can lead to better decisions.

Moreover, sustainability is becoming a key factor. Companies now prioritize eco-friendly practices. Wheel blasting technology can minimize waste and reduce energy consumption. Innovations in this area help businesses meet environmental regulations.

Tips: Keep an eye on emerging technologies. Staying updated on advancements can provide a competitive edge. Regularly training your team on new techniques is also beneficial. It ensures everyone is efficient in using these machines effectively.

2026 Top Wheel Blasting Machine Trends You Need to Know

| Trend |

Market Demand (% Change) |

Industry Growth Rate (% CAGR) |

Key Drivers |

| Automation and Digitalization |

15% |

6% |

Increased labor costs, demand for efficiency |

| Eco-Friendly Practices |

20% |

7% |

Regulatory pressures, sustainability initiatives |

| Increased Customization |

10% |

5% |

Customer demand for tailored solutions |

| Integration with IoT |

18% |

8% |

Smart factory initiatives, real-time monitoring |

| Safety Enhancements |

12% |

4% |

Regulatory compliance, employee safety priorities |

Home

Equipment

Vacuum Process Casting Molding Line

Automatic Flaskless Sand Molding Production Line

Sand Preparation Automation Line

Shot Blasting Peening Equipment

Stainless Steel Stripe Shot Blasting Machine

Steel Preservation Line

Roller Conveyor Shot Blasting Machine

Hook Type Shot Blasting Machine

Pass Through Monorail Shot Blasting Machine

Mesh Belt Shot Blasting Machine

Rotary Table Shot Blasting Machine

Trolley Type Shot Blasting Machine

Steel Pipe Shot Blasting Machine

Crawler Type Shot Blasting Machine

Rolling Drum Shot Blasting Machine

Automatic Titling Drum Shot Blasting Machine

Portable Shot Blasting Machine

Abrasive Blast Booth And Spray Paint Booth

Enviromental Dust Removal Equipment

Why Xinke

News Room

Blog

Contact Us