Understanding the Benefits of Plate Shot Blasting Machines for Industrial Applications

In the competitive landscape of industrial manufacturing, the efficiency and quality of surface preparation are paramount, leading to the increasing adoption of technologies such as the

Plate Shot Blasting Machine. According to a report by MarketsandMarkets, the shot blasting equipment market is projected to reach $4.27 billion by 2025, with a significant portion driven by advancements in

automation and the growing demand for corrosion-resistant surfaces in various sectors.

The Plate Shot Blasting Machine stands out as a crucial tool in this domain, offering superior performance in cleaning, pre-treating, and finishing metal plates and components. By enhancing surface properties and ensuring uniformity, these machines not only improve product longevity but also streamline production processes, thus reducing overall operational costs.

This article delves into the multifaceted benefits of Plate Shot Blasting Machines, providing insights into how they can transform industrial applications.

Benefits of Plate Shot Blasting Machines in Manufacturing Processes

Plate shot blasting machines play a critical role in various manufacturing processes by enhancing surface preparation, increasing durability, and ensuring better paint adhesion. As highlighted in industry projections, the shot blasting machine market is expected to grow from $1.41 billion in 2025 to $2.22 billion by 2032, reflecting a robust CAGR of 6.7%. This growth suggests a growing recognition of the technology's value in industries that require precise surface treatments, such as steel fabrication and heavy manufacturing.

The introduction of versatile models, like the economically efficient spinner hanger blast machines, showcases the innovation in this sector. These machines not only cater to flexibility in production but also maintain high operational standards despite lower production volumes. Companies are increasingly investing in advanced shot blasting technologies to meet stringent quality requirements while optimizing their manufacturing processes. The effective use of plate shot blasting not only enhances the overall quality of products but also drives operational efficiencies, making it a worthwhile investment in today's competitive industrial landscape.

Key Features of Plate Shot Blasting Machines for Enhanced Efficiency

Plate shot blasting machines have become vital in various industrial applications due to their capacity to enhance efficiency and improve surface preparation quality. These machines utilize high-velocity steel shots to clean, peen, or prepare metal surfaces, making them indispensable in industries like aerospace, automotive, and manufacturing. Recent advancements in technology have led to designs that focus on improving operational characteristics, including coverage and uniformity. For instance, a study introduced a new control cage design with concave and convex shapes aimed at optimizing the impact from the blasting shots, resulting in enhanced surface finish and reduced material waste.

The integration of simulation software into the planning phases of shot blasting systems is another significant trend transforming the industry. This allows for precise modeling of shot blasting processes, leading to better resource allocation and increased throughput. According to industry reports, organizations employing modern plate shot blasting machines can achieve efficiency gains up to 30% compared to traditional methods. Furthermore, the adoption of these advanced technologies is predicted to grow the market by over 8% annually in the coming years, as more facilities seek to improve their operational capabilities and adapt to stringent quality standards.

Comparative Analysis: Plate Shot Blasting vs. Other Surface Treatment Methods

Plate shot blasting is a surface treatment method that offers several advantages over traditional techniques like chemical cleaning and manual sanding. Unlike chemical cleaning, which may involve hazardous substances and lengthy application processes, plate shot blasting utilizes abrasive materials to efficiently remove contaminants, rust, and old paint without introducing harmful chemicals. This method not only enhances safety but also minimizes environmental impact, making it a preferred choice for many industries prioritizing sustainable practices.

When compared to manual sanding, plate shot blasting significantly improves efficiency and consistency. Manual sanding can be both time-consuming and labor-intensive, leading to variable results depending on the operator's skill level. In contrast, plate shot blasting machines ensure an even surface finish by delivering uniform treatment across the entire plate, reducing labor costs and time needed for surface preparation. Additionally, the ability to automate the blasting process allows for continuous production, further enhancing productivity and scalability in industrial applications.

Applications of Plate Shot Blasting Machines in Various Industries

Plate shot blasting machines play a crucial role in various industrial applications, particularly in industries where surface preparation is vital. These machines are essential for cleaning, finishing, and strengthening steel plates used in construction, automotive, and shipbuilding sectors. The shot blasting process enhances the surface quality by removing contaminants such as rust, scale, and old paint, thereby extending the lifespan of the materials.

The demand for plate shot blasting machines is projected to rise significantly, with market size expected to grow from $1.41 billion in 2025 to $2.22 billion by 2032, reflecting a compound annual growth rate (CAGR) of 6.7%. This growth is indicative of an increasing need for efficient surface preparation solutions across various industries. For instance, in the construction industry, higher quality standards often necessitate the use of shot blasting to ensure the structural integrity of steel components. Similarly, in the automotive sector, shot blasting machines are integral for pre-coating preparation, leading to better paint adhesion and finish quality. The versatility and effectiveness of plate shot blasting machines underscore their important role in modern manufacturing practices.

Maintenance Considerations for Optimal Performance of Shot Blasting Machines

Maintenance is a critical factor in ensuring the optimal performance of shot blasting machines. Regular inspections and servicing can prevent mechanical failures and extend the lifespan of the equipment. Operators should frequently check the condition of wear parts, such as nozzles and impellers, which can degrade due to continuous operation. Additionally, maintaining proper alignment and tension on belts and drive components is essential for efficiency and preventing unnecessary wear.

Proper cleaning of the machine is also vital. Accumulated dust and particles can lead to reduced performance and affect the quality of the blasting process. Scheduled downtime for thorough cleaning, along with the replacement of any worn components, should be part of a routine maintenance program. Moreover, keeping an accurate maintenance log helps track the performance and any issues that may arise, allowing for timely interventions and ultimately enhancing the reliability of shot blasting operations.

Home

Equipment

Vacuum Process Casting Molding Line

Automatic Flaskless Sand Molding Production Line

Sand Preparation Automation Line

Shot Blasting Peening Equipment

Stainless Steel Stripe Shot Blasting Machine

Steel Preservation Line

Roller Conveyor Shot Blasting Machine

Hook Type Shot Blasting Machine

Pass Through Monorail Shot Blasting Machine

Mesh Belt Shot Blasting Machine

Rotary Table Shot Blasting Machine

Trolley Type Shot Blasting Machine

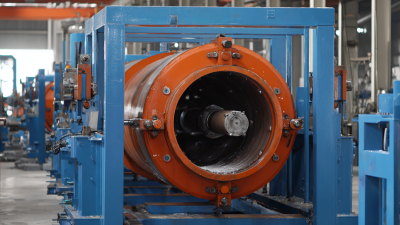

Steel Pipe Shot Blasting Machine

Crawler Type Shot Blasting Machine

Rolling Drum Shot Blasting Machine

Automatic Titling Drum Shot Blasting Machine

Portable Shot Blasting Machine

Abrasive Blast Booth And Spray Paint Booth

Enviromental Dust Removal Equipment

Why Xinke

News Room

Blog

Contact Us