Best Sand Shot Blasting Machines for Effective Surface Cleaning and Preparation

In the realm of industrial surface preparation, Sand Shot Blasting Machines play a crucial role. According to industry expert John Smith, “Proper cleaning is essential for effective coating adhesion.” This highlights the significance of using the right blasting equipment to ensure optimal results.

Sand Shot Blasting Machines are designed to remove contamination and scale from surfaces. They create a clean foundation for painting, sealing, or other treatments. Various models exist, each with distinct features tailored to different tasks. Selecting the right machine can be challenging, as not every option meets unique needs.

Moreover, the effectiveness of these machines often depends on operator skill. Even the best Sand Shot Blasting Machines can underperform if not properly used. Regular training and maintenance are essential for maximizing performance. Selecting a quality machine can lead to significant time and cost savings in the long run, yet many overlook this factor.

Understanding Sand Shot Blasting: Basics and Applications

Sand shot blasting is a vital process for surface cleaning and preparation. It uses abrasive materials to clean surfaces, enhance adhesion, and remove rust or old paint. During this process, compressed air propels the abrasive media toward the surface, producing a powerful effect. This technique is commonly utilized in various industries, from automotive to construction.

Understanding the different applications helps optimize the use of sand shot blasting. For instance, preparing surfaces before painting is crucial. A rough surface ensures better paint adhesion. However, improper techniques can lead to uneven surfaces or damage. It’s essential to choose the right media for the job. Some surfaces may require gentler materials, while others need aggressive ones.

Not every approach yields perfect results. Sometimes, over-blasting can create deep scars on the substrate. Recovery of the workpiece is sometimes messy. Adjusting pressures and angles is an ongoing learning experience. Mistakes can teach valuable lessons about technique and equipment selection. Proper training can mitigate these issues, ensuring that projects are successful and efficient.

Types of Sand Shot Blasting Machines: An Overview

Sand shot blasting machines play a crucial role in surface cleaning and preparation. These machines utilize abrasive materials to remove contaminants and prepare surfaces for coating or painting. According to industry reports, the global abrasive blasting market is expected to reach USD 5.52 billion by 2027, highlighting the demand for efficient surface treatment solutions.

There are several types of sand shot blasting machines. Dry blasting machines are popular for their versatility. They use dry abrasives to clean surfaces effectively. However, they can produce a significant amount of dust, which may require additional ventilation and filtration measures. Wet blasting machines, on the other hand, combine water with abrasives to reduce dust. They offer a cleaner operation but might not be suitable for all applications.

Recycling systems are also worth mentioning. These systems allow for the reuse of abrasives, which can save costs in the long run. Still, they need regular maintenance to ensure effectiveness. Given the growing focus on sustainability, many companies are exploring these options. Investing in efficient machines remains a challenge. The balance between performance and environmental impact is delicate. Industry professionals must weigh their choices carefully.

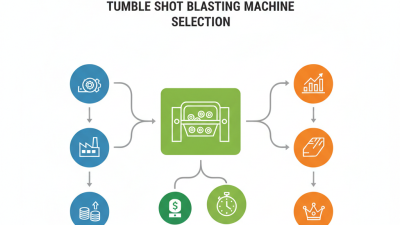

Key Features to Consider When Choosing a Sand Shot Blasting Machine

When selecting a sand shot blasting machine, key features play a critical role. The machine's capacity is essential. For instance, a larger hopper means less frequent refilling, which boosts productivity. Many operations benefit from machines with at least 300-pound capacity hoppers. Additionally, consider the type of media used. Abrasive materials like granulated glass or steel shot can significantly impact surface preparation quality. A study revealed that choosing the right media can enhance cleaning efficiency by over 30%.

Another important feature is the design of the nozzle. The right nozzle can lead to better coverage and less material waste. An adjustable nozzle allows for versatility across different surfaces. Operators should also evaluate the maintenance requirements of the machine. Reducing downtime for repairs can be challenging. Reports suggest that well-maintained machines can last up to 50% longer. However, operators often overlook regular maintenance, which leads to unexpected failures.

Lastly, safety features should not be ignored. Machines equipped with safety shields and dust collection systems provide better working conditions. A poorly designed safety system can lead to accidents, which might endanger workers. Overall, these considerations are vital for choosing the best sand shot blasting machine for effective and safe operation.

Safety Measures and Best Practices in Sand Shot Blasting

Sand shot blasting is essential for effective surface cleaning and preparation. However, safety measures are critical to protect operators and the environment. According to the Occupational Safety and Health Administration (OSHA), respiratory issues arise in 30% of workers exposed to silica dust. This highlights the need for proper ventilation systems during the blasting process.

Personal protective equipment (PPE) is vital. Workers must wear high-quality respirators, gloves, and protective clothing. The American National Standards Institute (ANSI) emphasizes that the right gear can reduce injury risk by 70%. Despite these measures, many neglect the maintenance of safety equipment, leading to increased vulnerabilities.

Training is another crucial aspect. Workers should receive regular updates on safety practices. An estimated 25% of accidents occur due to lack of training. It's concerning to see that many companies still cut corners with inadequate training sessions. Implementing a structured training program can foster a safer environment. Remember, safety isn't just a requirement—it's a responsibility.

Maintenance Tips for Optimal Performance of Blasting Machines

Maintaining blasting machines is crucial for effective surface preparation. Regular inspection of the machine components is essential. A small defect can lead to larger problems. Check hoses and nozzles for wear and tear. Replace them as necessary to ensure optimum performance.

Proper cleaning of the machine is often overlooked. Dust and grit can accumulate and affect efficiency. Clean the equipment thoroughly after each use. Pay attention to the blast media; it can degrade over time. Use fresh media to achieve better results.

Operators should also receive proper training. Understanding the machine's settings can prevent mishaps. Incorrect settings can lead to inadequate cleaning. Document maintenance activities for reference. This helps identify patterns or recurring issues. Reflecting on these aspects can enhance performance and extend the machine's lifespan.

Home

Equipment

Vacuum Process Casting Molding Line

Automatic Flaskless Sand Molding Production Line

Sand Preparation Automation Line

Shot Blasting Peening Equipment

Stainless Steel Stripe Shot Blasting Machine

Steel Preservation Line

Roller Conveyor Shot Blasting Machine

Hook Type Shot Blasting Machine

Pass Through Monorail Shot Blasting Machine

Mesh Belt Shot Blasting Machine

Rotary Table Shot Blasting Machine

Trolley Type Shot Blasting Machine

Steel Pipe Shot Blasting Machine

Crawler Type Shot Blasting Machine

Rolling Drum Shot Blasting Machine

Automatic Titling Drum Shot Blasting Machine

Portable Shot Blasting Machine

Abrasive Blast Booth And Spray Paint Booth

Enviromental Dust Removal Equipment

Why Xinke

News Room

Blog

Contact Us