How to Choose the Best Automatic Shot Blasting Machine for Your Needs

In the world of surface preparation and finishing, selecting the right Automatic Shot Blasting Machine is crucial for achieving optimal results. As industry expert John Smith, a leading figure in blasting technology, once stated, "The effectiveness of your surface treatment largely hinges on the quality and specification of your blasting equipment." This sentiment resonates throughout the industry, highlighting the importance of making an informed choice when investing in such machinery.

Choosing the best Automatic Shot Blasting Machine involves understanding your specific needs, including the type of materials you work with, the scale of your operations, and the desired finish. With an array of options available, from compact models for small workshops to large, high-capacity machines for industrial applications, navigating this landscape can be daunting. However, with the right knowledge and guidance, you can identify the machine that will not only meet your requirements but also enhance productivity and efficiency.

In this guide, we will explore the top 10 factors to consider when selecting an Automatic Shot Blasting Machine, ensuring you are well-equipped to make a decision that aligns with your operational goals and market needs. From technological advancements to cost-effectiveness, set the stage for your success in the competitive field of blasting and surface preparation.

Key Features to Look for in an Automatic Shot Blasting Machine

When selecting the best automatic shot blasting machine for your needs, it's essential to focus on

key features that ensure

efficiency, durability, and versatility. One of the

foremost attributes to consider is the machine's blasting system, which should effectively minimize

abrasive consumption while maximizing cleaning performance. According to a report by

The Abrasive Engineering Society, machines with optimized

blasting patterns can reduce material costs by up to 30%,

making them a wise investment for long-term operations.

Another critical feature to examine is the machine's

automation capabilities. Advanced systems often come

equipped with programmable controllers that can adapt to various cleaning tasks without needing manual

intervention. Research published in the Journal of Manufacturing Processes

indicates that automating shot blasting processes can enhance throughput by as much as

50%, significantly boosting productivity and reducing

labor costs. Additionally, look for machines with robust dust collection systems, as effective dust

management is crucial for maintaining a clean working environment and ensuring compliance with industry

health standards.

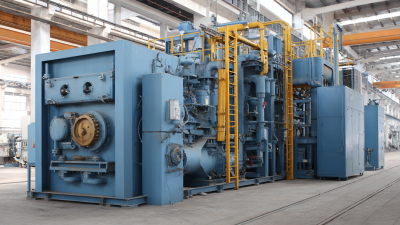

Understanding Different Types of Shot Blasting Machines Available

When choosing the best automatic shot blasting machine for your needs, it's essential to understand the various types available in the market. Each type of shot blasting machine serves a distinct purpose and comes with its unique specifications. Common types include tumble blast machines, which are ideal for processing small to medium-sized components; cabinet blast machines, designed for manual operation and precise finishing; and conveyor blast systems that allow for continuous processing of larger items. Understanding these differences helps in selecting the right equipment that aligns with your production requirements.

The increasing demand for efficiency in surface preparation is driving advancements in shot blasting technology. For instance, newer models are integrating automated controls and enhanced safety measures, which not only improve operational efficiency but also reduce labor costs. Furthermore, developments in materials used for abrasive media are making the blast process more environmentally friendly. As the market for shot blasting machines is expected to grow significantly in the coming years, staying informed about these variations will be crucial for businesses aiming to enhance their surface treatment processes.

How to Choose the Best Automatic Shot Blasting Machine for Your Needs

| Type of Shot Blasting Machine |

Application |

Media Used |

Production Capacity (kg/hr) |

Cost Range (USD) |

| Spinner Hanger |

Automotive Parts |

Steel Shot |

300-500 |

$25,000 - $50,000 |

| Tumble Blast |

Metal Fabrication |

Aluminum Oxide |

200-600 |

$15,000 - $35,000 |

| Continuous Blast |

Heavy Equipment |

Steel Grit |

400-700 |

$30,000 - $70,000 |

| Room Size Blast |

Large Components |

Glass Bead |

500-800 |

$40,000 - $80,000 |

| Portable Blast |

Surface Preparation |

Sand |

50-150 |

$5,000 - $10,000 |

Evaluating the Cost vs. Performance of Shot Blasting Machines

When selecting an automatic shot blasting machine, it’s essential to evaluate the cost versus performance to ensure you’re making a wise investment. While cheaper machines may seem attractive, they often compromise on durability, efficiency, and quality of work. Higher-priced models might offer advanced features and greater efficiency, leading to lower operating costs in the long run. It is crucial to analyze both the initial cost and the operating expense, factoring in maintenance, energy consumption, and expected lifespan.

Tips: Before making a decision, conduct a thorough analysis of the machine specifications. Look for models that provide the best balance between performance and cost-effectiveness. Reading user reviews and seeking recommendations from industry colleagues can help identify reliable options. Additionally, consider the compatibility of the machine with your existing operations to avoid additional costs related to integration.

Moreover, consider the type of materials you will be blasting and the required surface finish. Different machines are designed for specific applications, so aligning your needs with the capabilities of the machine is key. Investing in a versatile model that can adapt to various processes might save you money and time in the future. Remember, prioritizing performance over just the purchase price can lead to better outcomes in your blasting operations.

Top Brands and Models to Consider for 2025

When selecting the best automatic shot blasting machine for your operations in 2025, it's essential to consider leading brands and their standout models. Companies like Graco, Wheelabrator, and Pangborn have established a reputation for delivering high-quality machines tailored to various industrial needs. Graco's EcoQuip line, for example, offers advanced features that allow for efficient and effective surface preparation, making it a favorite among professionals looking for both quality and eco-friendliness.

Another notable brand is Wheelabrator, known for its robust lineup of shot blasting machines, including the HP Series, which is designed for heavy-duty use in demanding environments. These machines are optimized for performance and durability, ensuring long-term investment returns.

Lastly, Pangborn's innovative technology and customizable solutions offer flexibility for businesses of different sizes, allowing you to choose models that best fit your operational requirements. By focusing on these top brands and models, you can make a more informed decision that aligns with your specific blasting needs for the upcoming year.

Maintenance and Support: Ensuring Longevity of Your Shot Blasting Equipment

Proper maintenance and support play a pivotal role in ensuring the longevity and efficiency of your automatic shot blasting equipment. Regular maintenance routines should be established to inspect and replace worn-out parts, clean components, and calibrate the machine. This not only prevents unexpected breakdowns but also extends the lifespan of the equipment, ensuring consistent performance over time. Following the manufacturer's maintenance guidelines is crucial, as these often include specific procedures tailored to the unique needs of the machine.

Additionally, investing in reliable support services is essential. When choosing a shot blasting machine, consider the availability of professional technicians who can provide troubleshooting, repairs, and timely service. A manufacturer that offers comprehensive support plans can significantly ease the burden of ownership, allowing operators to focus on production rather than equipment issues. Furthermore, training and resources provided by the manufacturer can empower your team to perform basic maintenance and troubleshooting, further enhancing the longevity and efficiency of your shot blasting equipment.

Home

Equipment

Vacuum Process Casting Molding Line

Automatic Flaskless Sand Molding Production Line

Sand Preparation Automation Line

Shot Blasting Peening Equipment

Stainless Steel Stripe Shot Blasting Machine

Steel Preservation Line

Roller Conveyor Shot Blasting Machine

Hook Type Shot Blasting Machine

Pass Through Monorail Shot Blasting Machine

Mesh Belt Shot Blasting Machine

Rotary Table Shot Blasting Machine

Trolley Type Shot Blasting Machine

Steel Pipe Shot Blasting Machine

Crawler Type Shot Blasting Machine

Rolling Drum Shot Blasting Machine

Automatic Titling Drum Shot Blasting Machine

Portable Shot Blasting Machine

Abrasive Blast Booth And Spray Paint Booth

Enviromental Dust Removal Equipment

Why Xinke

News Room

Blog

Contact Us