How to Choose the Best H Beam Shot Blasting Machine for Your Project

When embarking on a project that requires the precision and efficiency of an H Beam Shot Blasting Machine, selecting the right equipment is crucial. According to industry expert John Smith, a renowned specialist in metal surface treatment technologies, "Choosing the correct shot blasting machine can significantly enhance the quality of the finish and extend the lifespan of H beams." This insight underscores the importance of a well-informed selection process for businesses aiming to improve their operational performance.

The decision-making process involves understanding the specific requirements of your project, including the size, type, and volume of H beams you will be working with. An H Beam Shot Blasting Machine not only ensures thorough cleaning and surface preparation, but it also plays a vital role in improving the adhesion of subsequent coatings, thus enhancing the overall quality of the final product. Recognizing the diverse models and features available on the market will empower project managers and engineers to make informed choices that align with their operational goals.

In summary, investing time in evaluating different H Beam Shot Blasting Machines will yield significant benefits in productivity and finished product quality. As the industry continues to evolve with technological advancements, staying abreast of the latest developments and expert recommendations will serve as an invaluable asset for any project.

Factors to Consider for Selecting H Beam Shot Blasting Machines

When selecting an H Beam shot blasting machine for your project, there are several key factors to consider to ensure you make the best choice. Firstly, evaluate the machine’s capacity and size compatibility with your specific H Beam dimensions. It is essential to choose a model that can efficiently process the largest beams you plan to use while fitting within your operational space. Additionally, the machine's throughput capacity should align with your production needs to minimize downtime and maximize efficiency.

Another critical aspect to consider is the type of abrasive material used in the blasting process. Different projects may require different types of abrasives depending on the level of cleaning or surface preparation needed. It's also important to assess the machine’s automation features, as advanced controls can enhance ease of operation and consistency in blast results.

Furthermore, consider the machine's energy consumption and maintenance requirements to ensure long-term operational sustainability and cost-effectiveness. By focusing on these factors, you can make an informed decision that will meet your project's demands effectively.

Understanding Different Types of H Beam Shot Blasting Technologies

When selecting the best H beam shot blasting machine for your project, it is crucial to understand the different types of shot blasting technologies available. The two primary types include turbine shot blasting and airless shot blasting. Turbine shot blasting systems utilize a series of rotating turbines to propel abrasive materials towards the H beam surface, providing effective and uniform cleaning. According to recent industry reports, turbines can achieve higher efficiencies and better coverage, often reducing processing times by 30% compared to traditional methods.

Airless shot blasting, on the other hand, relies on compressed air to propel abrasives at high velocities. This method can be advantageous for projects requiring precision and control over the blasting process. Data from a 2022 market analysis indicates a growing demand for airless systems due to their versatility and lower overall operational costs, which can be up to 20% less than turbine systems for certain applications. Selecting the right technology involves considering factors such as project scale, required surface finish, and available budget, ensuring optimal performance and results tailored to specific production needs.

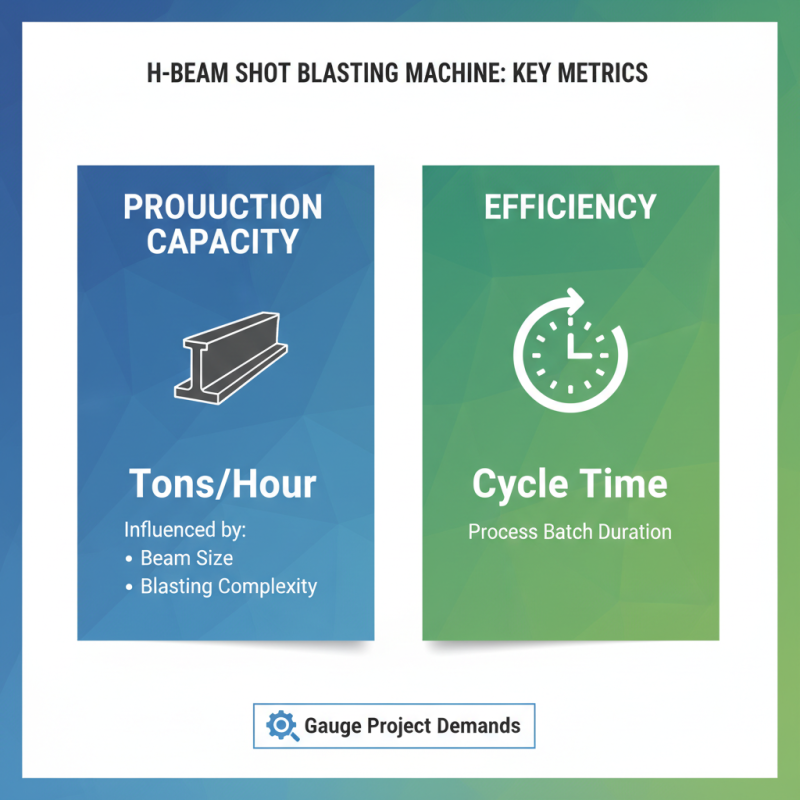

Evaluating Production Capacity and Efficiency Metrics in Machines

When selecting the best H beam shot blasting machine, understanding production capacity and efficiency metrics is crucial. These metrics help to gauge how well a machine can meet the specific demands of your project. A machine's production capacity is typically measured in tons per hour and is influenced by factors such as the size of the H beams and the complexity of blasting required. Additionally, evaluating the cycle time—how long it takes to process a batch—can give you insights into its overall efficiency.

Tips: When assessing machines, consider their material handling capabilities. Machines that can accommodate different beam sizes and feed rates can enhance flexibility in production.

Another important metric to examine is the energy consumption of the machine. Efficient machines should use less power while maintaining high output levels. Look for technologies that optimize this balance, as they can lead to significant cost savings over time.

Tips: Conduct a thorough analysis of machine features that promote energy efficiency, such as automatic dust collection systems and variable speed controls, to ensure you select a model that aligns with your operational goals.

Cost Analysis: Budgeting for H Beam Shot Blasting Equipment

When budgeting for H beam shot blasting equipment, it's essential to consider both the initial investment and the long-term operational costs. The price of H beam shot blasting machines can vary significantly depending on their size, features, and production capacity. A thorough cost analysis should account for not only the purchase price but also installation fees, maintenance expenses, and the potential costs of downtime. By carefully assessing these factors, you can avoid unexpected financial strains and ensure that your project stays on budget.

In addition to the direct costs, consider the return on investment (ROI) associated with the efficiency and longevity of the equipment. High-quality shot blasting machines may come at a higher upfront price but can lead to reduced labor costs, lower material waste, and increased throughput. Therefore, it is crucial to balance the initial expenditure against the potential savings and increased productivity over time. A well-planned budget that includes all of these elements will help you make an informed decision and select the best H beam shot blasting machine suitable for your project's specific needs.

Safety Standards and Compliance for Shot Blasting Operations

In any shot blasting operation, adhering to safety standards and compliance regulations is paramount to ensuring not only the well-being of workers but also the efficiency of the entire process. According to the Occupational Safety and Health Administration (OSHA), approximately 2.3 million workplace injuries occur annually, with a significant number related to abrasive blasting tasks. Proper safety measures, such as utilizing personal protective equipment (PPE) and ensuring that machines meet industry safety standards, can greatly reduce these incidents.

Moreover, compliance with standards set forth by organizations such as the American National Standards Institute (ANSI) and the National Fire Protection Association (NFPA) is essential for shot blasting operations. For instance, ANSI Z49.1 provides guidelines for safety in welding and allied processes, which includes the operation of shot blasting machines. Ensuring that equipment complies with these regulations not only mitigates risks but also promotes a culture of safety that can improve productivity. According to a report from the National Institute for Occupational Safety and Health (NIOSH), workplaces that prioritize safety compliance can experience a 20-30% reduction in operational downtime, ultimately leading to cost savings and enhanced project outcomes.

Home

Equipment

Vacuum Process Casting Molding Line

Automatic Flaskless Sand Molding Production Line

Sand Preparation Automation Line

Shot Blasting Peening Equipment

Stainless Steel Stripe Shot Blasting Machine

Steel Preservation Line

Roller Conveyor Shot Blasting Machine

Hook Type Shot Blasting Machine

Pass Through Monorail Shot Blasting Machine

Mesh Belt Shot Blasting Machine

Rotary Table Shot Blasting Machine

Trolley Type Shot Blasting Machine

Steel Pipe Shot Blasting Machine

Crawler Type Shot Blasting Machine

Rolling Drum Shot Blasting Machine

Automatic Titling Drum Shot Blasting Machine

Portable Shot Blasting Machine

Abrasive Blast Booth And Spray Paint Booth

Enviromental Dust Removal Equipment

Why Xinke

News Room

Blog

Contact Us