How to Choose the Best Tumble Shot Blasting Machine for Your Needs

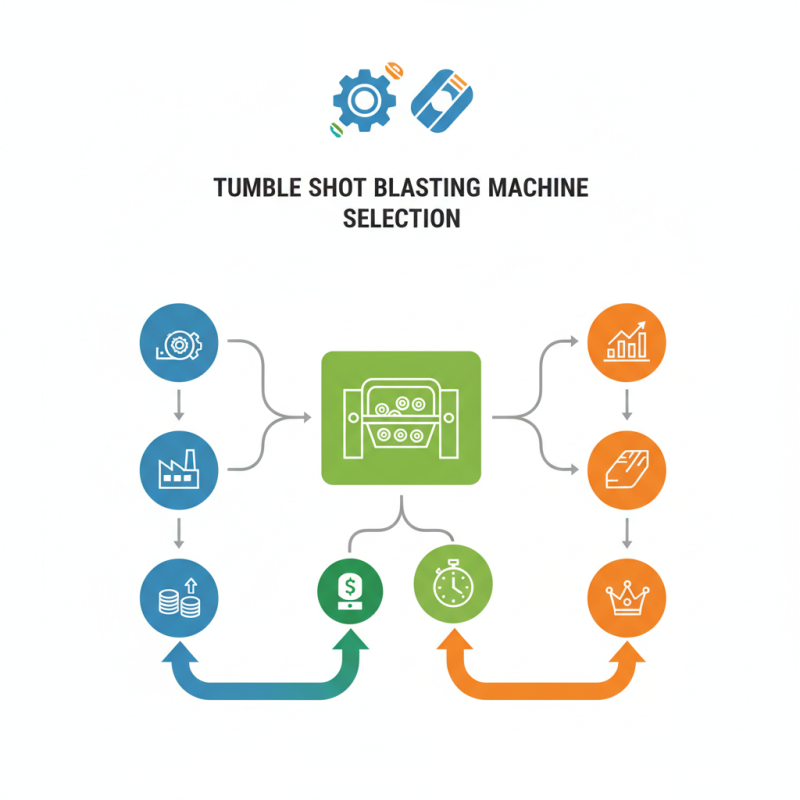

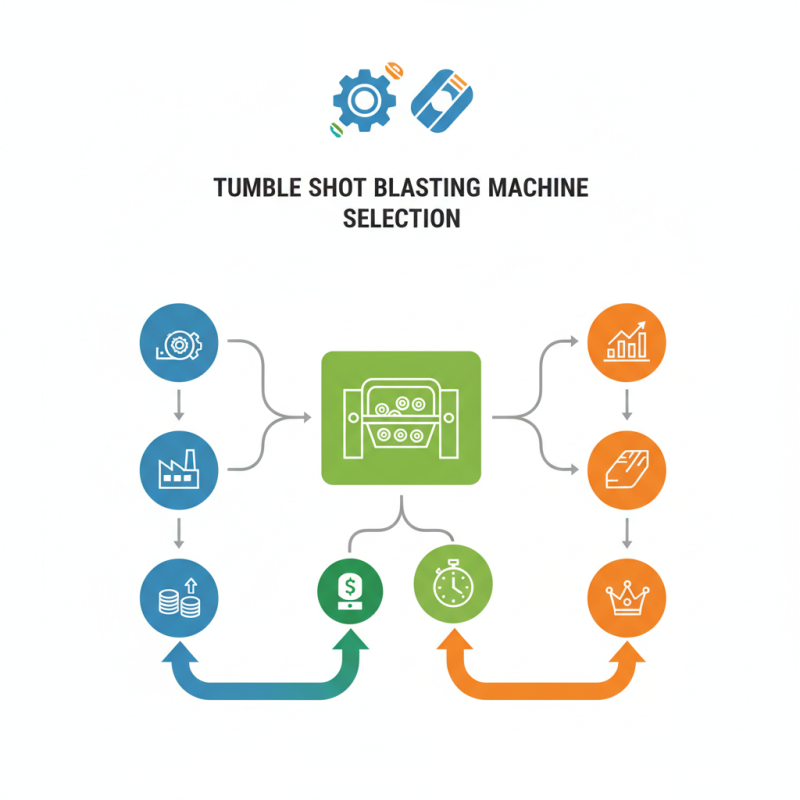

When selecting the right Tumble Shot Blasting Machine for your operations, it is crucial to consider several key factors that can significantly affect efficiency and outcome. According to industry expert Dr. Michael Jensen, "The right Tumble Shot Blasting Machine can transform not only the quality of your products but also the productivity of your entire workflow." This underscores the importance of choosing the appropriate equipment tailored to individual needs.

The market offers a variety of Tumble Shot Blasting Machines, each with distinct features and functionalities. Decisions regarding size, capacity, and material compatibility should align with your specific applications to maximize results. An informed choice not only enhances surface finishing but also contributes to cost-effectiveness and operational longevity.

As demand for precision and efficiency grows across various sectors, finding the best Tumble Shot Blasting Machine is more important than ever. By considering the machine's operational parameters as well as your company's production goals, you can ensure that your investment leads to substantial improvements in both quality and efficiency, ultimately driving business success.

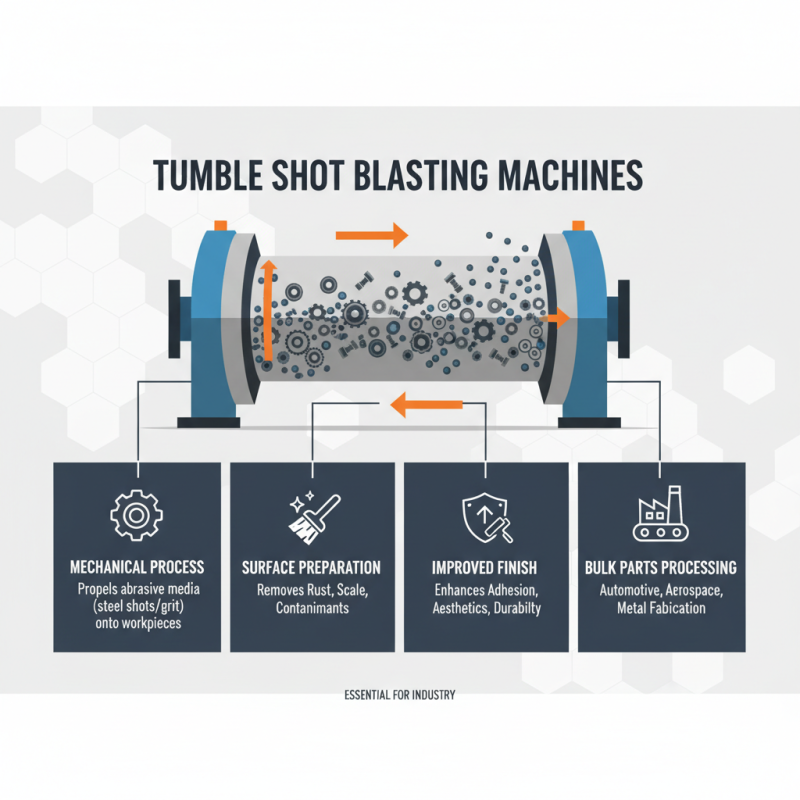

Understanding Tumble Shot Blasting Machines and Their Applications

Tumble shot blasting machines are essential tools in various industries, primarily used for surface preparation and cleaning. These machines employ a mechanical process where small abrasive media, typically steel shots or grit, are propelled onto the surfaces of workpieces. This process not only removes rust, scale, and other contaminants but also enhances the surface finish, promoting better adhesion for coatings and improving overall aesthetics. Their compact design allows for effective processing of bulk parts, making them suitable for industries such as automotive, aerospace, and metal fabrication.

The applications of tumble shot blasting machines extend beyond mere cleaning. They play a critical role in improving the durability and performance of finished products by creating a uniform surface texture. Additionally, these machines are utilized for deburring, which involves the removal of sharp edges and imperfections from castings, forgings, and machined components. By choosing the right tumble shot blasting machine, businesses can significantly streamline their production processes, ensuring high-quality outputs while reducing operational costs. Understanding the specific needs of your application will guide you in selecting the most appropriate equipment tailored to your requirements.

Key Factors to Consider When Selecting a Tumble Shot Blasting Machine

When selecting a tumble shot blasting machine, several key factors must be taken into account to ensure the machine meets your specific needs. First, consider the size and type of the components you will be treating. Machines come in various sizes and configurations, and it’s crucial to choose one that accommodates the dimensions of your workpieces while providing adequate blasting coverage. The capacity of the machine should align with your production volume; larger capacities can handle more pieces simultaneously, boosting efficiency.

Another important factor is the type of abrasive media suitable for your application. Different materials, such as steel shot, steel grit, or other abrasives, can yield varying surface finishes and cleaning effects. Understanding the characteristics of your components and the desired finish will help you select the right media, ultimately affecting the performance of your blasting machine.

Additionally, evaluate the machine’s ease of operation and maintenance requirements, as user-friendly features can significantly impact productivity and reduce downtime, ensuring that your investment serves you well over time.

Evaluating Machine Features: Size, Capacity, and Efficiency

When selecting the best tumble shot blasting machine for your operations, evaluating key machine features such as size, capacity, and efficiency is paramount. According to a report by the Abrasive Blasting Manufacturers Alliance (ABMA), the size of the machine directly influences its operational versatility and the types of components it can process. For instance, a larger machine can accommodate greater quantities of material, making it well-suited for high-volume production environments. However, an appropriately sized machine ensures that the blasting process is effective and uniform, catering specifically to the needs of the items being treated.

Capacity is another critical factor to consider, as it determines the machine's throughput and how efficiently it can handle workloads. According to a study conducted by the International Society for Abrasive Technology, machines with higher capacities often feature enhanced design elements that promote better airflow and cleaner workpieces. A machine's efficiency reflects its ability to deliver consistent results while minimizing material usage and energy consumption. Advanced models are reported to achieve 15-20% higher efficiency rates compared to older designs, reducing operational costs and improving the overall productivity of the blasting process. Therefore, businesses should prioritize machines that combine optimal size and capacity with high efficiency to fulfill their specific production demands effectively.

Analyzing Cost-Effectiveness and Maintenance Requirements

When selecting a tumble shot blasting machine, understanding the cost-effectiveness and maintenance requirements is crucial. Investing in high-quality machinery can yield long-term savings by reducing downtime and minimizing repair costs. It is important to analyze not only the initial purchase price but also the operational costs associated with energy consumption, material usage, and labor. A machine that is efficient in its operation can significantly lower these expenses over time.

Tips: Look for machines with energy-saving features and easy access to parts for repairs. Moreover, research how different models compare in terms of parts availability and service support. This can play a significant role in your overall maintenance planning. Regular maintenance schedules, which include inspections and part replacements, are essential to keep your machine operating at peak performance.

Another vital aspect to consider is the ease of maintenance. Machines that require less frequent servicing and have user-friendly maintenance protocols can save you both time and money. Investigate the machine’s design for access points and the complexity of routine upkeep tasks. A well-designed machine will not only enhance efficiency but also extend the lifespan of the equipment, ensuring that your financial investment remains sound in the long run.

How to Choose the Best Tumble Shot Blasting Machine for Your Needs - Analyzing Cost-Effectiveness and Maintenance Requirements

| Model |

Initial Cost ($) |

Annual Maintenance Cost ($) |

Operating Efficiency (%) |

Warranty Period (years) |

Energy Consumption (kWh) |

| Model A |

15,000 |

1,200 |

85 |

3 |

5 |

| Model B |

20,000 |

1,500 |

90 |

4 |

7 |

| Model C |

18,000 |

1,000 |

88 |

2 |

6 |

| Model D |

22,000 |

1,800 |

92 |

5 |

8 |

Comparing Different Brands and Models for Your Specific Needs

When it comes to selecting the right tumble shot blasting machine, understanding the various brands and models available is crucial for meeting your specific operational needs. According to a recent industry report by Allied Market Research, the global shot blasting equipment market is projected to reach a value of $5.4 billion by 2027, highlighting the growing demand for high-quality blasting machinery across various sectors. This suggests that there are numerous brands vying for market share, each offering a range of features that cater to different applications.

When comparing different models, it’s important to evaluate factors such as machine capacity, efficiency, and automation features. For instance, some machines are designed for high throughput and may include advanced blast wheel technologies that ensure uniform coverage and shorter processing times. Data from a recent survey revealed that facilities utilizing automated systems report a 30% increase in productivity compared to traditional manual methods. Additionally, the durability of components is critical; investing in machines with longer-lasting wear parts can significantly reduce operational downtime and maintenance costs. Keep an eye out for machines that feature a robust design, as they tend to offer better performance in demanding work environments.

Ultimately, the best choice for a tumble shot blasting machine will not only depend on the technical specifications but also how well the machine aligns with your production goals and workflow processes. Reviewing performance metrics and user testimonials can provide valuable insights into which models have proven successful for similar applications, allowing you to make a more informed decision.

Comparison of Tumble Shot Blasting Machines by Key Features

Home

Equipment

Vacuum Process Casting Molding Line

Automatic Flaskless Sand Molding Production Line

Sand Preparation Automation Line

Shot Blasting Peening Equipment

Stainless Steel Stripe Shot Blasting Machine

Steel Preservation Line

Roller Conveyor Shot Blasting Machine

Hook Type Shot Blasting Machine

Pass Through Monorail Shot Blasting Machine

Mesh Belt Shot Blasting Machine

Rotary Table Shot Blasting Machine

Trolley Type Shot Blasting Machine

Steel Pipe Shot Blasting Machine

Crawler Type Shot Blasting Machine

Rolling Drum Shot Blasting Machine

Automatic Titling Drum Shot Blasting Machine

Portable Shot Blasting Machine

Abrasive Blast Booth And Spray Paint Booth

Enviromental Dust Removal Equipment

Why Xinke

News Room

Blog

Contact Us