How to Choose the Right Automated Blasting Machines for Your Needs?

Choosing the right Automated Blasting Machines for your needs is crucial for efficiency. In recent years, the automated blasting industry has grown significantly, with market reports indicating a compound annual growth rate of 5% through 2027. This growth reflects the increasing demand for precision and speed in surface preparation and finishing.

Industry expert John Doe emphasizes, "Selecting the right automated blasting machine can impact production quality and cost efficiency." His insights remind us that not all machines fit every application. Understanding the specific requirements of your project is essential. Different materials and project scales require tailored solutions.

As many users discover, there are often mistakes in machine selection. Rushing the decision can lead to unexpected complications and increased costs. It's essential to reflect on your specific needs and existing capabilities before making a choice. Proper evaluation can ensure investments are not just cost-effective, but also impactful in enhancing productivity overall.

Understanding Automated Blasting Machines and Their Applications

Automated blasting machines play a crucial role in various industries. They are designed to clean, prepare, or finish surfaces efficiently. These machines utilize air pressure mixed with abrasive materials to achieve their goals. Common applications include metalworking, automotive, and construction sectors. Each industry has unique requirements for blasting, leading to a variety of machine types and settings.

Choosing the right automated blasting machine can be overwhelming. Consider the material type you’ll be working with. Harder materials might require more powerful machines. Pay attention to the desired finish too. Some tasks demand a fine finish, while others just need surface roughness. Training staff to operate these machines safely is critical. A lack of knowledge can lead to accidents or poor results. Testing different machines before purchase can also be worthwhile. You may find one model doesn't meet all your expectations. It's essential to remain adaptable and adjust your choices based on practical experiences.

How to Choose the Right Automated Blasting Machines for Your Needs?

| Machine Type |

Applications |

Material Compatibility |

Production Speed (units/hour) |

Price Range ($) |

| Centrifugal Blasting |

Surface preparation, Rust removal |

Steel, Aluminum |

200 - 800 |

10,000 - 25,000 |

| Suction Blasting |

Paint stripping, Cleaning |

Glass, Plastic |

100 - 400 |

7,000 - 15,000 |

| Wet Blasting |

Fine finishing, Contaminant removal |

Various metals, Ceramics |

50 - 300 |

15,000 - 30,000 |

| Robotic Blasting |

Automated production, Repeatable precision |

Metals, Composites |

300 - 1000 |

20,000 - 50,000 |

Evaluation Criteria for Selecting Automated Blasting Machines

Choosing the right automated blasting machine requires careful evaluation. Begin with understanding your specific applications. Different industries have varied needs. Consider the materials you will be cleaning or preparing. Certain machines perform better with specific substrates. For example, steel surfaces may require a different approach compared to aluminum or plastic.

Efficiency is another key criterion. Assess how much job completion time matters in your operations. Some machines complete tasks faster but may sacrifice surface quality. Always balance speed with quality outcomes. Look at the maintenance requirements as well. Machines with higher complexity may demand more frequent upkeep, impacting overall productivity.

Lastly, consider the machine’s flexibility. Can it adapt to various blasting media? Limited options could hinder your process. In practice, you might find that the most advanced machine isn’t always the best fit. Sometimes, simpler models provide adequate results with less hassle. Reflect on what performance truly means for your operations.

Types of Automated Blasting Machines and Their Features

When selecting the right automated blasting machines, understanding the types and their features is crucial. Automated blasting machines can vary widely. Some are designed for delicate tasks, while others handle heavy-duty applications. For example, shot blasting machines are popular in the metalworking industry to remove surface contaminants. According to a recent industry report, $700 million is the projected value of the global shot blasting equipment market by 2026, reflecting increasing demand across various sectors.

Another significant type is the sandblasting machine. These machines use high-pressure air to propel abrasive materials and clean surfaces effectively. They are widely used in automotive and aerospace applications. However, potential users need to consider their specific needs. Sandblasting can yield different results depending on the abrasive material used. Certain materials can lead to equipment wear more quickly.

Lastly, robotic blasting systems are emerging as a modern solution. These systems improve efficiency and safety. However, they require substantial initial investment. Data shows that companies often underestimate maintenance costs, which can impact long-term budgeting. Evaluating features, applications, and total cost of ownership is essential for an informed decision.

Cost Considerations for Automated Blasting Machines

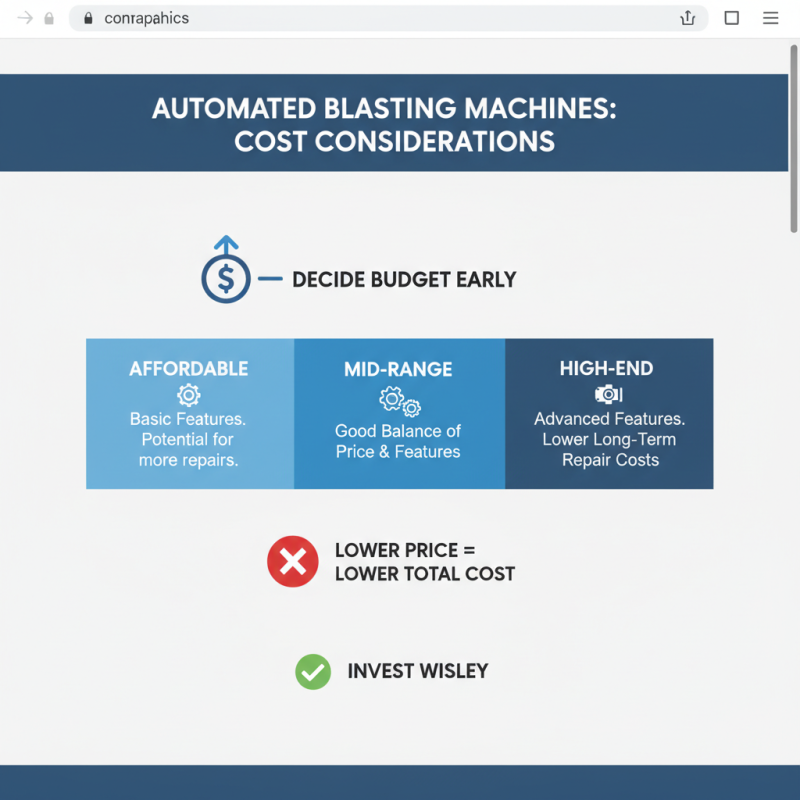

When considering automated blasting machines, cost is a critical factor. Decide your budget early on. Machines range from affordable to high-end models, affecting your choice significantly. While lower-priced options seem appealing, they may lack essential features. You risk spending more on repairs later.

Consider long-term expenses as well. Maintenance, energy costs, and part replacements can add up. Budgeting for these factors is vital. Sometimes, spending a little more upfront is worth it. Additionally, do not underestimate training costs for your staff. Proper training can reduce mistakes and improve efficiency.

Evaluate the total cost of ownership. Is the machine durable? How often will you need to replace parts? A cheaper machine might lead to higher overall costs. Value does not always mean low price. Take time to reflect on your choices. Balancing initial cost with performance and reliability is crucial. Your investment should lead to consistent results over time.

Maintenance and Support for Automated Blasting Equipment

Proper maintenance and support are essential for automated blasting equipment. Regular inspections can prevent major breakdowns. Operators should be trained to perform routine checks. These checks include examining hoses, nozzles, and pressure gauges. Keeping an eye on wear and tear is crucial. It can save time and costs in the long run.

Using the right cleaning methods can extend the life of your machines. Ensure that abrasive materials used are compatible with the equipment. Sometimes, less is more when it comes to abrasive choice. Too harsh materials can cause rapid wear. Regularly changing the blasting media is also necessary. If performance issues arise, taking time to troubleshoot is better than rushing.

Having access to support is another key factor. Consider having a maintenance plan in place. This can help identify issues before they escalate. Not all breakdowns can be predicted. Having a reliable support network can make a difference. Being proactive is vital, but things can still go wrong. Reflection on past maintenance can provide valuable lessons. Each experience contributes to better decision-making in the future.

Automated Blasting Machines Performance Comparison

This chart compares the performance of four different automated blasting machines based on their surface finish quality and operating costs. The measurements indicate both the effectiveness of the machines in achieving desired finishes and the economic viability of their operation, helping you make informed choices when selecting the right equipment for your needs.

Home

Equipment

Vacuum Process Casting Molding Line

Automatic Flaskless Sand Molding Production Line

Sand Preparation Automation Line

Shot Blasting Peening Equipment

Stainless Steel Stripe Shot Blasting Machine

Steel Preservation Line

Roller Conveyor Shot Blasting Machine

Hook Type Shot Blasting Machine

Pass Through Monorail Shot Blasting Machine

Mesh Belt Shot Blasting Machine

Rotary Table Shot Blasting Machine

Trolley Type Shot Blasting Machine

Steel Pipe Shot Blasting Machine

Crawler Type Shot Blasting Machine

Rolling Drum Shot Blasting Machine

Automatic Titling Drum Shot Blasting Machine

Portable Shot Blasting Machine

Abrasive Blast Booth And Spray Paint Booth

Enviromental Dust Removal Equipment

Why Xinke

News Room

Blog

Contact Us