How to Choose the Right Rotary Shot Blasting Machine?

Choosing the right rotary shot blasting machine can be a daunting task. Industry expert John Smith once said, “Selecting the right equipment makes all the difference in efficiency and quality.” A rotary shot blasting machine is essential for industries focusing on surface preparation. It enhances durability and improves the overall finish of products.

When faced with numerous options, the key is understanding your specific needs. Each machine type serves different purposes. For instance, some machines are suitable for large-scale operations, while others are designed for smaller tasks. This distinction can profoundly affect your production line's efficiency.

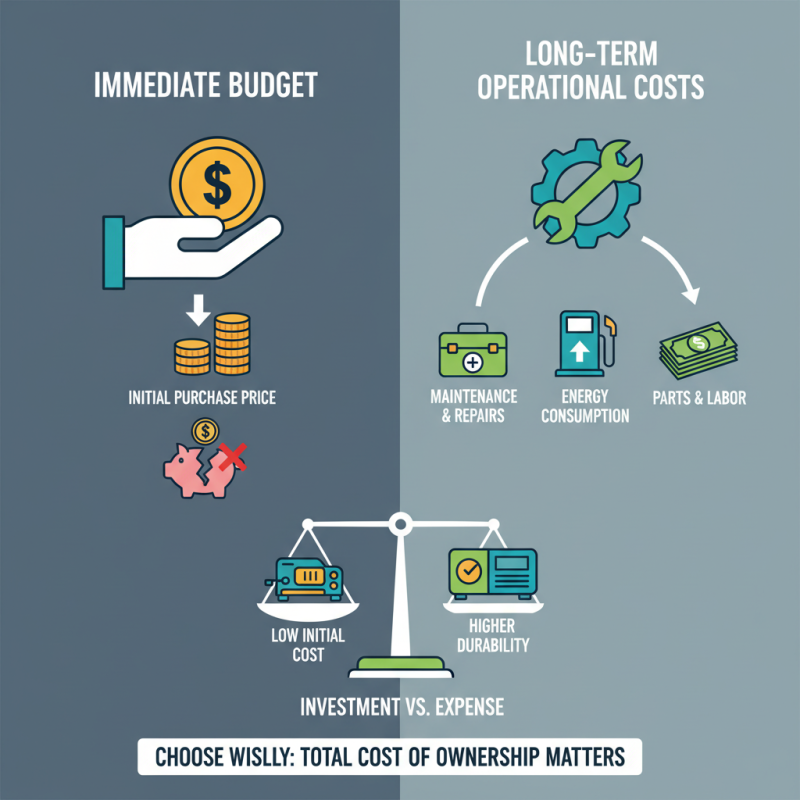

Ignoring machine specifications can lead to poor performance. Take time to consider factors like power, speed, and cost-effectiveness. Your choice will influence the longevity of your investment. Focusing solely on price may result in unexpected maintenance costs later. Reflect carefully on what you truly need before making a decision.

Understanding the Basics of Rotary Shot Blasting Machines

Rotary shot blasting machines are essential for surface preparation. They work by propelling small steel shots at high speeds onto surfaces. This action cleans, deburrs, and strengthens the material. Understanding how they function can help you make better choices later. The process is simple yet powerful.

These machines come in various types and sizes. Each is suited for different tasks. You need to consider your specific needs when choosing one. For example, larger machines handle bigger projects. Smaller machines are perfect for detail work. However, cost and space may affect your decision. Sometimes, what you need isn’t what you think.

When choosing a rotary shot blasting machine, reflect on your priorities. Quality and speed often clash. Higher quality may take longer, while fast options might not meet your standards. Finding balance is crucial. Think about the kind of materials you will be working with. Also, consider how frequently the machine will be used. Ask yourself, will this machine still serve my needs in the long run? These reflections lead to more informed choices.

Identifying Your Project Requirements and Specifications

When selecting a rotary shot blasting machine, understanding your project requirements is crucial. Consider the materials you will be working with. Different materials require different levels of cleaning and surface preparation. This is important for achieving the desired finish.

Tip: Analyze the size of the components you plan to blast. Smaller machines may not accommodate larger pieces effectively. You might end up with uneven results if the machine is too small. Aim for a balance between power and size.

Evaluate the specific tasks your project demands. Will you need high pressure or a gentle touch? Each task can call for a unique approach. A one-size-fits-all solution may lead to subpar outcomes. Taking time to reflect on this will pay off later.

Tip: Don’t forget to factor in ease of use and maintenance. Complicated machinery can slow down your progress. Machines that seem simple may have hidden complexities. Look for user-friendly options that fit your workflow.

Evaluating Different Types of Rotary Shot Blasting Machines

When selecting a rotary shot blasting machine, understanding the types available is crucial. There are various models in the market, each with specific features and capabilities. Machines differ in size, power, and method. Some machines are designed for heavy-duty work, while others are more suitable for lighter tasks. Assessing the scope of your projects will guide your choice.

Consider your workspace. A larger machine might be beneficial for scaling, yet it could limit mobility. Compact models often fit into tighter spaces easily. Evaluate your production needs. If you're handling continuous workloads, an efficient and durable model is key. Thicker materials may require a more robust machine.

Tips: Look into maintenance needs. Some machines require less upkeep. This can save time and costs. Also, check the machine's compatibility with the abrasives you plan to use. Not all machines handle every type of shot. Take notes on your findings and reflect on your requirements. This can direct you toward the best fit for your needs.

Performance Comparison of Different Rotary Shot Blasting Machines

Key Features to Look for in a Quality Shot Blasting Machine

When selecting a rotary shot blasting machine, key features are essential. Look for a robust construction. A heavy-duty frame ensures longevity and stability during operation. The material used should resist wear and tear from abrasives. A machine that can handle multiple abrasive types is a plus. This flexibility can save costs in the long run.

Dust collection systems are vital. A quality shot blasting machine should have an efficient dust removal feature. This keeps the workspace clean and reduces health hazards. Noise levels are another aspect to consider. A quieter model can improve worker comfort.

Adjustable speed settings are beneficial. They allow for customized blasting based on the task. This can optimize efficiency but might require careful calibration. Operators must be trained, as improper use could lead to poor results. Reflecting on these aspects can help you make a more informed choice.

How to Choose the Right Rotary Shot Blasting Machine? - Key Features to Look for in a Quality Shot Blasting Machine

| Feature |

Description |

Importance |

| Durability |

Made from high-quality materials to withstand wear and tear. |

High |

| Efficiency |

Ability to clean surfaces quickly with minimal energy consumption. |

High |

| Versatility |

Suitable for various applications, including different materials and sizes. |

Medium |

| Ease of Use |

User-friendly controls and maintenance features. |

High |

| Safety Features |

Incorporates safety mechanisms to protect users. |

High |

| Customizability |

Ability to adjust settings for specific blasting requirements. |

Medium |

Home

Equipment

Vacuum Process Casting Molding Line

Automatic Flaskless Sand Molding Production Line

Sand Preparation Automation Line

Shot Blasting Peening Equipment

Stainless Steel Stripe Shot Blasting Machine

Steel Preservation Line

Roller Conveyor Shot Blasting Machine

Hook Type Shot Blasting Machine

Pass Through Monorail Shot Blasting Machine

Mesh Belt Shot Blasting Machine

Rotary Table Shot Blasting Machine

Trolley Type Shot Blasting Machine

Steel Pipe Shot Blasting Machine

Crawler Type Shot Blasting Machine

Rolling Drum Shot Blasting Machine

Automatic Titling Drum Shot Blasting Machine

Portable Shot Blasting Machine

Abrasive Blast Booth And Spray Paint Booth

Enviromental Dust Removal Equipment

Why Xinke

News Room

Blog

Contact Us