10 Effective Tips for Choosing the Right Shot Peening Machine for Your Needs

In the world of industrial manufacturing, selecting the right Shot Peening Machine is crucial for enhancing the durability and performance of components. Industry expert Dr. James Turner, a leading authority in surface optimization technologies, emphasizes that “the efficiency of your production line can greatly depend on the quality of your shot peening process.” With this in mind, businesses must carefully evaluate their specific needs and the capabilities of various machines available on the market.

This guide presents ten effective tips for choosing the most suitable Shot Peening Machine tailored to your unique requirements. Whether you are seeking increased operational efficiency, precision in surface treatment, or compliance with industry standards, understanding the essential features and functionalities of these machines is paramount. From material selection to operational costs, every aspect plays a vital role in making an informed choice.

As you embark on the journey to identify the right Shot Peening Machine, consider the insights shared by experts in the field, as well as the latest technological advancements. With careful consideration and research, you can ensure that your investment will provide significant returns in both product longevity and overall productivity.

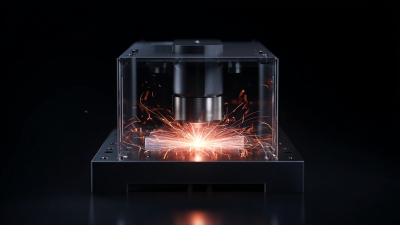

Understanding the Different Types of Shot Peening Machines Available in 2025

In 2025, the market for shot peening machines is set to experience significant growth, with experts projecting an expansion from $664.7 million in 2024 to approximately $1,005.6 million. This robust increase reflects a growing recognition of the critical role shot peening plays in enhancing the durability and performance of components across various industries, particularly aerospace, automotive, and manufacturing. As the demand for these machines rises, understanding the different types available becomes essential for businesses seeking to invest wisely.

There are several types of shot peening machines tailored to meet specific operational needs. These include wheel-type, air-operated, and robotic shot peening machines, each offering unique advantages in terms of efficiency, precision, and flexibility. As the industry evolves, advancements in technology will introduce more innovative solutions, making it crucial for companies to evaluate their requirements carefully. By doing so, they can select a machine that not only aligns with their operational goals but also positions them competitively in an expanding market projected to reach between $1.33 billion and $2.22 billion over the next decade.

10 Effective Tips for Choosing the Right Shot Peening Machine for Your Needs

| Type of Shot Peening Machine |

Application |

Media Used |

Control System |

Cost Range ($) |

| Centrifugal Wheel |

Heavy-duty applications |

Steel shot, glass beads |

Automated |

20,000 - 50,000 |

| Air Blast |

Precision applications |

Alumina oxide, ceramic media |

Manual or semi-automated |

5,000 - 15,000 |

| Continuous Flow |

High-volume production |

Steel shot, stainless steel |

Fully automated |

30,000 - 80,000 |

| Robotic Peening |

Complex geometries |

Ceramic beads, glass beads |

Advanced robotics |

50,000 - 100,000 |

| Portable Peener |

Field use |

Steel shot, plastic media |

Basic control |

2,000 - 8,000 |

Evaluating the Key Features of Shot Peening Machines for Enhanced Performance

When selecting a shot peening machine, it is essential to evaluate its key features to ensure optimal performance for specific applications. The effectiveness of the machine largely hinges on parameters such as intensity control, coverage, and media type. According to a report by the International Journal of Precision Engineering and Manufacturing, machines that offer adjustable intensity levels can enhance the process by allowing operators to tailor the peening effect to the materials being treated. This adaptability is crucial in industries like aerospace and automotive, where precision and surface integrity are paramount.

Moreover, machines with advanced automation capabilities can significantly boost productivity. A study from the Society for Protective Coatings noted that automated shot peening machines reduce labor costs by up to 30% while increasing throughput and consistency in operation. In addition to automation, the choice of media—be it steel shot, glass beads, or ceramic beads—plays a pivotal role in achieving the desired surface finish and fatigue resistance.

Experts suggest that selecting the appropriate media can lead to improvements in component lifespan by as much as 25%, making it vital to thoroughly assess these factors when choosing a shot peening machine.

Assessing the Importance of Media Type in Shot Peening Processes and Costs

When selecting a shot peening machine, understanding the media type is crucial. Different media materials can significantly influence the effectiveness of the peening process. For instance, steel shot offers durability and strength, making it ideal for tough materials that require deep surface treatment. Conversely, glass beads provide a gentler impact, which is beneficial for delicate surfaces that need a more controlled peening effect. The media type not only affects the peening results but also determines the overall cost and maintenance of the machine.

Additionally, the choice of media directly correlates with operational efficiency. Using the wrong type of media may lead to increased wear on the machinery and a higher frequency of replacement, raising costs over time. It’s essential to evaluate the materials and desired outcomes when choosing a peening machine, ensuring that the media selected aligns with the specific requirements of your project. A thoughtful approach to media selection can optimize performance while minimizing costs, making it an integral part of the shot peening process.

Analysis of Media Types Used in Shot Peening Processes

Comparing the Efficiency and Maintenance of Top Shot Peening Machines in 2025

In 2025, the shot blasting machine market is set to experience significant growth, with projections indicating an increase from $1.41 billion to $2.22 billion by 2032. This surge, corresponding to a compound annual growth rate (CAGR) of 6.7%, highlights the increasing demand for efficient surface treatment solutions across various industries.

When selecting a shot peening machine, it is crucial to compare the efficiency and maintenance requirements of available systems to ensure optimal performance and cost-effectiveness.

Efficiency in shot peening machines is primarily determined by their operational capabilities and the quality of the finished surface. Machines that offer adjustable parameters for shot size, speed, and impact angle can provide superior outcomes while accommodating a range of materials. Moreover, maintenance is a critical factor; machines designed with ease of access for routine checks and repairs will not only reduce downtime but also enhance longevity. By focusing on these elements, businesses can make informed decisions that align with their production needs and budget constraints for the year ahead.

Choosing the Right Supplier: Evaluating Warranty, Support, and Industry Reputation

When selecting a shot peening machine, choosing the right supplier is as critical as the machine itself. A supplier's warranty can indicate the quality and reliability of their equipment. According to a recent industry report by the Machinery Manufacturers Association, 85% of manufacturers consider warranty length as a significant factor in their purchasing decisions. A robust warranty not only protects your investment but also reflects the manufacturer's confidence in their product's durability and efficiency.

Support services offered by the supplier should also be carefully evaluated. A manufacturer that provides comprehensive technical support can significantly enhance your operational efficiency. The National Institute of Standards and Technology (NIST) reported that companies with access to responsive supplier support experience a 30% reduction in downtime. Additionally, assessing the supplier’s industry reputation can help ensure you’re making an informed choice. According to a survey conducted by the Association for Manufacturing Technology, 70% of businesses prefer suppliers with a proven track record of reliability and customer satisfaction. Thus, thorough research into warranty, support, and reputation can lead to a well-rounded decision in selecting a shot peening machine supplier.

Home

Equipment

Vacuum Process Casting Molding Line

Automatic Flaskless Sand Molding Production Line

Sand Preparation Automation Line

Shot Blasting Peening Equipment

Stainless Steel Stripe Shot Blasting Machine

Steel Preservation Line

Roller Conveyor Shot Blasting Machine

Hook Type Shot Blasting Machine

Pass Through Monorail Shot Blasting Machine

Mesh Belt Shot Blasting Machine

Rotary Table Shot Blasting Machine

Trolley Type Shot Blasting Machine

Steel Pipe Shot Blasting Machine

Crawler Type Shot Blasting Machine

Rolling Drum Shot Blasting Machine

Automatic Titling Drum Shot Blasting Machine

Portable Shot Blasting Machine

Abrasive Blast Booth And Spray Paint Booth

Enviromental Dust Removal Equipment

Why Xinke

News Room

Blog

Contact Us