How to Effectively Use a Tumble Blasting Machine for Surface Finishing?

Surface finishing is crucial in various industries. A Tumble Blasting Machine offers an efficient solution for achieving high-quality finishes. This machine uses abrasive materials to remove imperfections from surfaces, making it a popular choice.

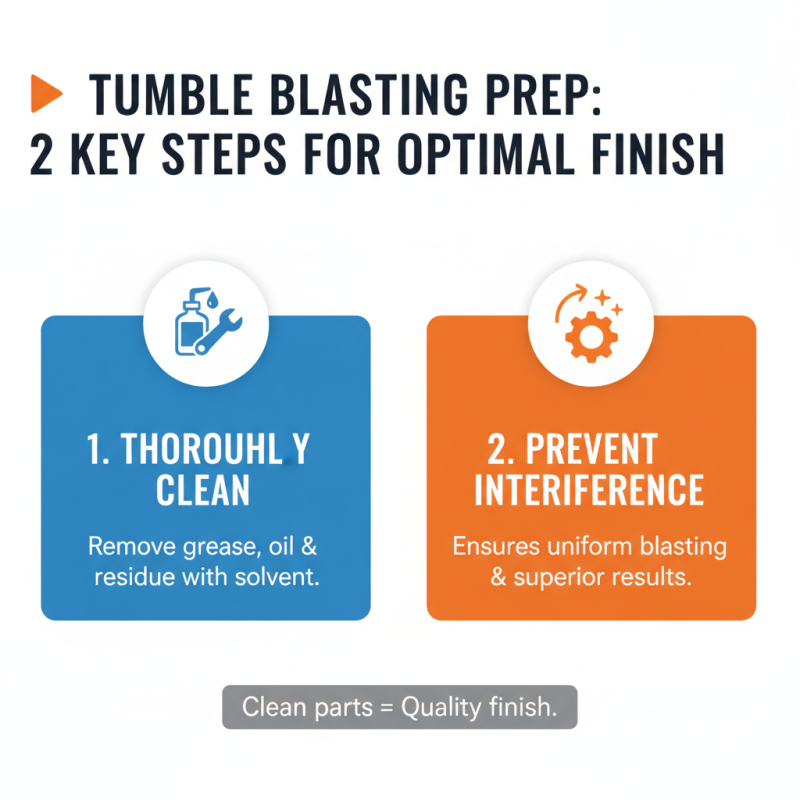

When using a Tumble Blasting Machine, preparation is key. Operators must select appropriate abrasives for the specific material being treated. This choice can significantly impact the final finish. It’s also important to regularly check machine settings to ensure optimal performance. Neglecting these aspects can lead to inconsistent results.

Experience with a Tumble Blasting Machine often reveals challenges. Many users struggle with achieving uniform surface finishes. This highlights the need for continuous monitoring and adjustment. It's not uncommon for operators to learn from mistakes. Reflecting on these experiences can lead to better practices in the future.

Understanding Tumble Blasting Machines and Their Applications

Tumble blasting machines are essential tools for surface finishing in various industries. They employ a unique method of abrasive blasting, utilizing projectiles to create a smooth, clean surface. According to recent industry reports, nearly 30% of manufacturers rely on tumble blasting for improving surface quality. This method is effective for components with complex geometries, such as brackets and housings.

In practice, the type of abrasive media used can significantly influence the results. Common options include steel shot, glass beads, and aluminum oxide. Each has distinct properties, affecting surface roughness and the overall finishing time. For example, steel shot provides a more aggressive finish but may require frequent media replacement. Operators frequently overlook the necessity of adjusting machine settings to align with media type.

Furthermore, the machine's capacity to handle varying batch sizes can present challenges. While some models efficiently process small parts, others are better for larger objects. Misuse or improper loading can lead to inconsistent results. The machine's design must match the intended application, emphasizing the importance of evaluating specific requirements before use. Regular calibration can also enhance performance but is often neglected.

Operating a Tumble Blasting Machine: Step-by-Step Guide

Operating a Tumble Blasting Machine requires careful attention to detail. Start by ensuring the workspace is clean and free from debris. Inspect the machine for any wear or damage before starting. This precaution helps prevent accidents. Safety gear is essential. Wear gloves, goggles, and ear protection consistently.

Load the components into the tumbler evenly. Overloading can lead to poor results. Observe how the parts interact with the abrasive material. Sometimes, parts may not receive uniform blasting. Adjust the position as needed. This can affect overall surface finish quality.

Tips: Regular maintenance is vital. Check for clogs in the abrasive system. This keeps the machine running smoothly. Experiment with different media types for varied finishes. Each part has unique characteristics; your approach should reflect that. Monitor the blasting time closely. Too long can cause unwanted wear on your components. A mistake in timing can lead to disappointing results.

Maintaining and Troubleshooting Tumble Blasting Equipment

Maintaining tumble blasting equipment is crucial for consistent performance. Regular inspection helps identify issues early. According to industry reports, equipment downtime can lead to a loss of up to 20% in productivity. Keeping a detailed log of maintenance activities is essential. This practice allows operators to track wear and tear, thus preventing unexpected failures.

Troubleshooting is a skill that operators must develop. Common problems include uneven surface finishes and excessive media consumption. These issues often signal improper machine settings. A startling statistic shows that nearly 30% of blasting defects result from setup errors. Visual inspections should be part of the troubleshooting regimen. Operators should look for signs of media buildup or misaligned components.

Improper visibility can hinder effective troubleshooting. Without sufficient light, operators might overlook critical signs of wear. The right lighting is just as vital as the equipment itself. Reflection on past maintenance practices can guide future improvements. Continuous education on newer techniques can help in resolving recurring problems.

Home

Equipment

Vacuum Process Casting Molding Line

Automatic Flaskless Sand Molding Production Line

Sand Preparation Automation Line

Shot Blasting Peening Equipment

Stainless Steel Stripe Shot Blasting Machine

Steel Preservation Line

Roller Conveyor Shot Blasting Machine

Hook Type Shot Blasting Machine

Pass Through Monorail Shot Blasting Machine

Mesh Belt Shot Blasting Machine

Rotary Table Shot Blasting Machine

Trolley Type Shot Blasting Machine

Steel Pipe Shot Blasting Machine

Crawler Type Shot Blasting Machine

Rolling Drum Shot Blasting Machine

Automatic Titling Drum Shot Blasting Machine

Portable Shot Blasting Machine

Abrasive Blast Booth And Spray Paint Booth

Enviromental Dust Removal Equipment

Why Xinke

News Room

Blog

Contact Us