Understanding the Efficiency of Pipe Blasting Machines in Industrial Applications

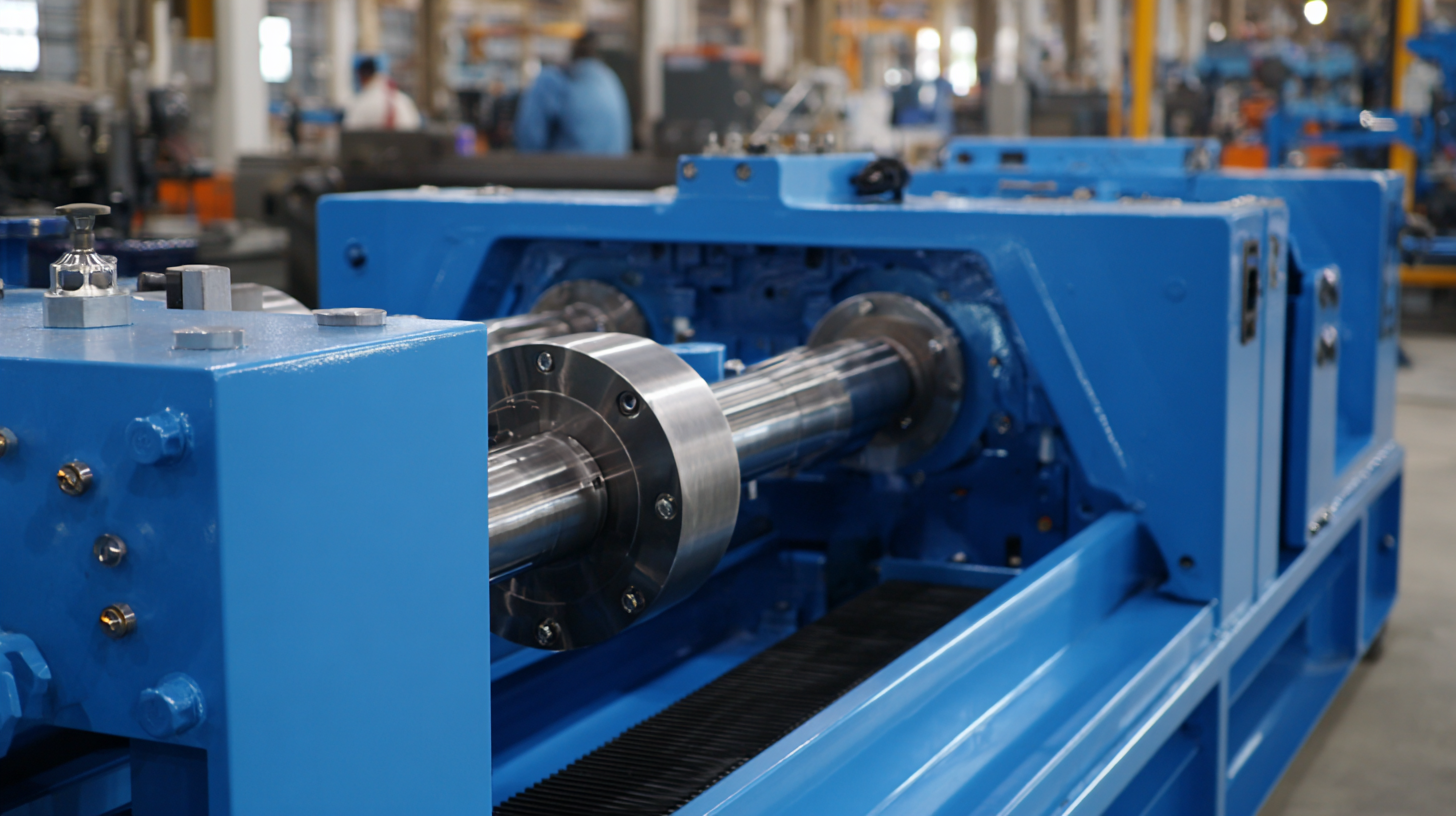

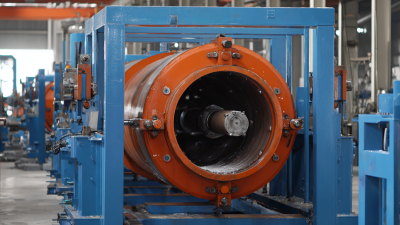

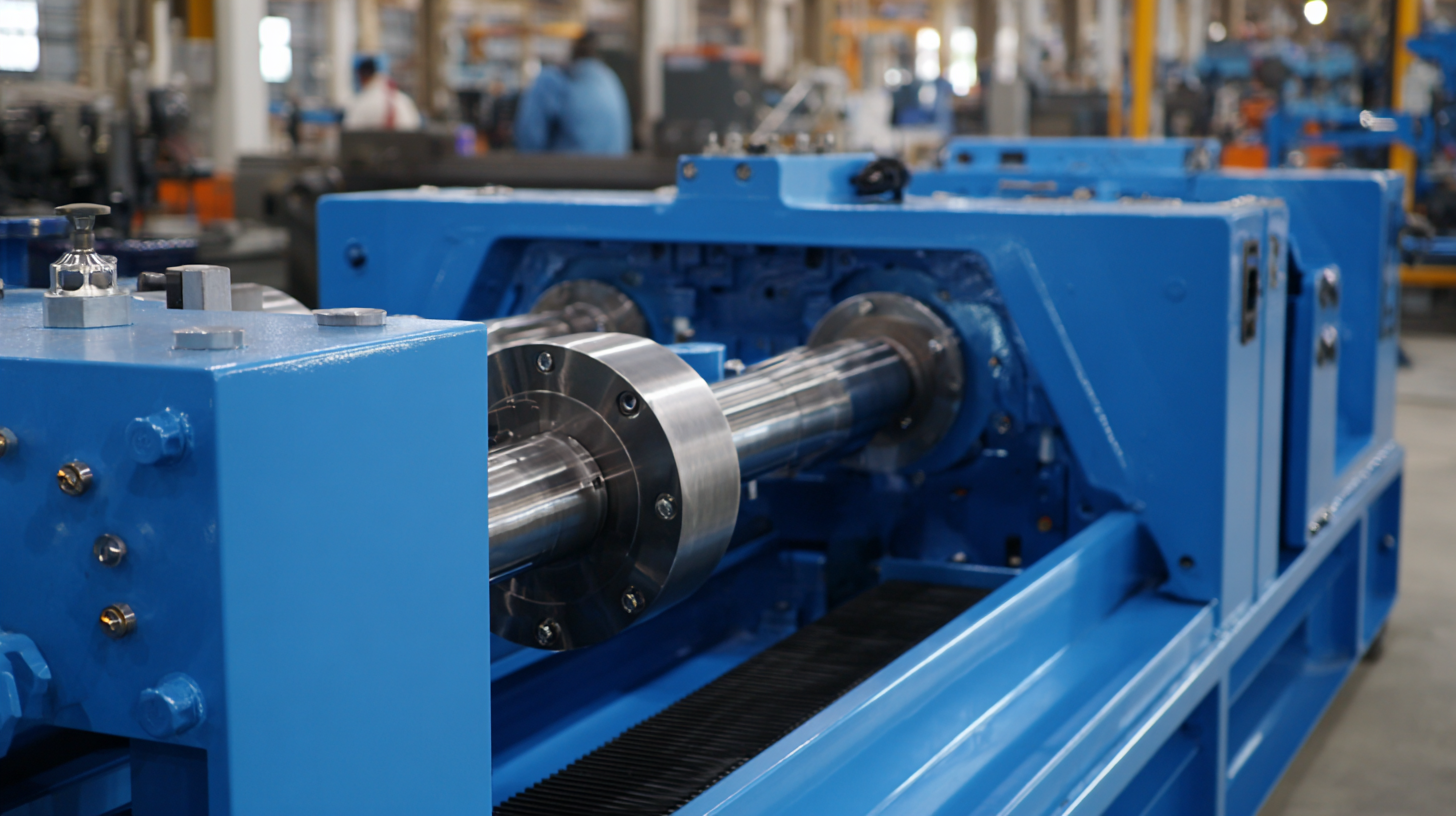

In the ever-evolving landscape of industrial applications, the efficiency and effectiveness of various machinery play a pivotal role in determining operational success. Among these, the Pipe Blasting Machine has emerged as a critical tool for enhancing surface preparation and ensuring the longevity of pipelines across various sectors. This "How to" guide delves into the mechanics, capabilities, and best practices associated with Pipe Blasting Machines, illuminating their significance in both maintenance and new construction projects. By understanding the operational principles and optimal usage of these machines, industry professionals can streamline their processes, reduce downtime, and maximize productivity. Whether you are looking to improve coating adhesion, remove corrosion, or prepare surfaces for welding, mastering the utilization of Pipe Blasting Machines is paramount for achieving superior results in today's competitive industrial environment.

Advantages of Pipe Blasting Machines in Various Industries

Pipe blasting machines have become indispensable in various industries due to their efficiency and effectiveness in surface preparation. One key advantage is their ability to significantly reduce the time required for cleaning and preparing surfaces, which is critical in sectors like aerospace and automotive manufacturing. A study from the International Journal of Surface Engineering Technology highlights that pipe blasting can enhance cleaning speed by up to 40%, allowing businesses to streamline their operations and improve overall productivity.

In addition to time savings, pipe blasting machines provide superior cleaning results compared to traditional methods. Research indicates that these machines can achieve a surface profile that is optimal for adhesion, which is crucial for a robust coating application. Industries such as oil and gas have reported a 30% increase in corrosion resistance when using pipe blasting for surface preparation, as it effectively removes contaminants like rust and scales.

Tip: When selecting a pipe blasting machine, consider the specific material and surface requirements of your project to ensure optimal performance. Regular maintenance of the equipment can also prevent unexpected downtimes, thereby improving operational efficiency. It's crucial to stay updated on industry standards to choose the right machine that meets safety and effectiveness benchmarks.

Key Technical Specifications Enhancing Machine Efficiency

In the realm of industrial applications, the efficiency of pipe blasting machines is significantly enhanced by various key technical specifications. These machines are engineered to optimize not only their performance but also the overall workflow within an industrial setting. Technical advancements such as automated control systems, precise pressure management, and advanced material selection for the blasting nozzles play a crucial role in boosting efficiency. By incorporating real-time data analytics, operators can fine-tune processes and achieve better outcomes with reduced operational costs, aligning with broader industry trends of embracing digital solutions.

Moreover, just as artificial intelligence is revolutionizing sectors like healthcare and human resources by enhancing efficiency and productivity, the integration of intelligent systems in pipe blasting technology is paving the way for smarter industrial practices. The use of predictive maintenance software can anticipate machine failures before they occur, minimizing downtime and ensuring consistent output quality. These innovations reflect a growing emphasis on sustainability and energy efficiency in industrial applications, showcasing the potential for advanced technology to transform traditional processes into more streamlined and effective operations.

Comparative Analysis: Pipe Blasting vs. Traditional Cleaning Methods

The comparative analysis of pipe blasting machines against traditional cleaning methods showcases the efficiency and effectiveness of modern abrasive technologies in industrial applications. Unlike conventional cleaning techniques that often rely on manual labor and chemical solvents, pipe blasting utilizes high-pressure systems to remove rust, scale, and contaminants. This method not only enhances the speed of the cleaning process but also ensures a uniform finish, significantly improving the quality of surface preparation prior to coatings or repairs.

Moreover, in various sectors such as manufacturing and construction, the adaptability of pipe blasting machines offers significant advantages. The controlled environment enables operators to optimize operational parameters, similar to how rigorous methodologies are employed in studies evaluating the effectiveness of pollutant control measures in industries like steel manufacturing. By employing precision techniques akin to those used for biosynthetic gene cluster identification in marine actinomycetes, pipe blasting can achieve measurable results that traditional methods often fail to deliver, thereby making it a preferred choice for maintaining industrial standards and environmental compliance.

Economic Impact of Implementing Pipe Blasting Technology

The economic impact of implementing pipe blasting technology in industrial applications is significant, offering both cost savings and enhanced productivity. By utilizing advanced blasting machines, companies can automate the cleaning process of pipes, thus reducing labor costs and minimizing downtime. This efficiency translates into quicker turnaround times for maintenance and production schedules, allowing businesses to operate more swiftly and effectively in competitive markets.

Furthermore, the precision of pipe blasting technology leads to lower material waste and decreased environmental impact. The clean surfaces achieved through this method ensure better adhesion in subsequent processes, such as coating and welding, which not only enhances product quality but also promotes longer service life for the pipelines. Overall, the initial investment in pipe blasting machines leads to substantial long-term savings and contributes positively to a company's bottom line while fostering an eco-friendly approach to industrial operations.

Efficiency of Pipe Blasting Machines in Industrial Applications

Future Trends and Innovations in Pipe Blasting Machine Design

The future of pipe blasting machine design is poised for significant transformation, driven by innovative technologies and a focus on digital integration. With advancements in automation and data analytics, these machines are expected to become more precise and efficient, minimizing material wastage and enhancing productivity in industrial applications. The incorporation of smart technologies will allow for real-time monitoring and adjustments, ensuring optimal performance under varying conditions.

Furthermore, industry leaders are recognizing the importance of collaboration with customers to tailor solutions that meet specific operational needs. As companies explore new product lines, there will likely be an emphasis on environmentally friendly materials and practices, aligning with global sustainability goals. As the market evolves, ongoing research and development efforts will contribute to a more sophisticated understanding of blasting processes, ultimately leading to innovative designs that set new standards in the industry.

Understanding the Efficiency of Pipe Blasting Machines in Industrial Applications - Future Trends and Innovations in Pipe Blasting Machine Design

| Parameter |

Current Value |

Future Projection |

Technological Innovation |

| Efficiency Rate (%) |

75 |

85 |

Automated control systems |

| Average Noise Level (dB) |

95 |

85 |

Noise reduction technology |

| Maintenance Frequency (months) |

6 |

12 |

Predictive maintenance software |

| Energy Consumption (kWh) |

250 |

200 |

Energy-efficient motors |

| Material Removal Rate (cm³/h) |

1200 |

1500 |

Advanced nozzle design |

Home

Equipment

Vacuum Process Casting Molding Line

Automatic Flaskless Sand Molding Production Line

Sand Preparation Automation Line

Shot Blasting Peening Equipment

Stainless Steel Stripe Shot Blasting Machine

Steel Preservation Line

Roller Conveyor Shot Blasting Machine

Hook Type Shot Blasting Machine

Pass Through Monorail Shot Blasting Machine

Mesh Belt Shot Blasting Machine

Rotary Table Shot Blasting Machine

Trolley Type Shot Blasting Machine

Steel Pipe Shot Blasting Machine

Crawler Type Shot Blasting Machine

Rolling Drum Shot Blasting Machine

Automatic Titling Drum Shot Blasting Machine

Portable Shot Blasting Machine

Abrasive Blast Booth And Spray Paint Booth

Enviromental Dust Removal Equipment

Why Xinke

News Room

Blog

Contact Us