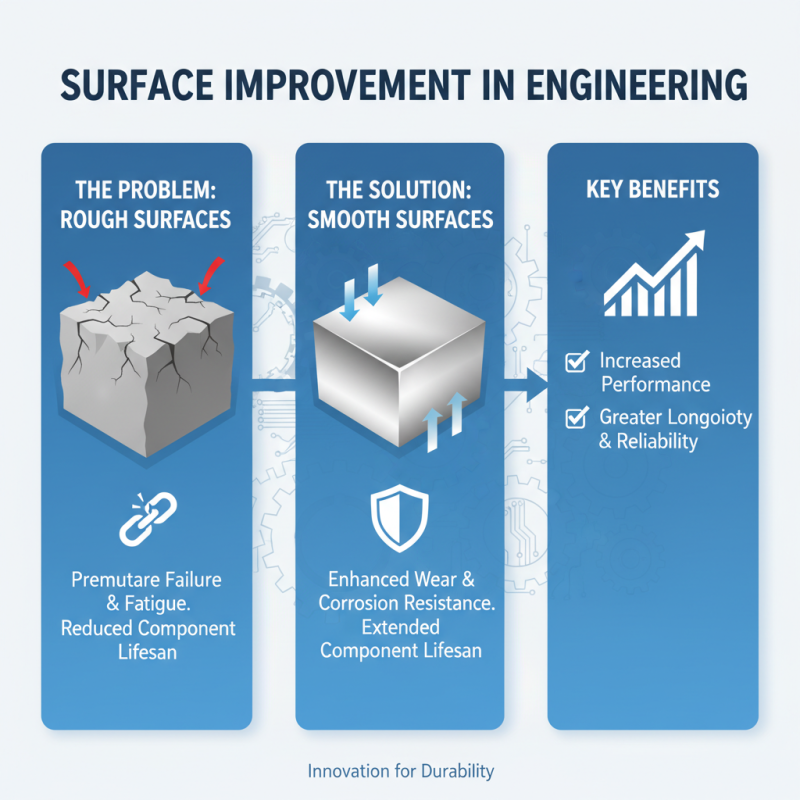

Why is a Shot Peening Machine Essential for Surface Improvement?

In the manufacturing sector, surface quality is crucial. A Shot Peening Machine plays a vital role in enhancing component durability. This machine uses high-velocity particles to impact a surface. The process creates residual stress, which strengthens the material.

Industries rely on shot peening to improve fatigue resistance. It transforms the surface, making parts more resilient. The benefits are evident in aerospace and automotive sectors. However, not every application may require a machine of this kind. Some may find it excessive or costly.

Ultimately, the decision to use a Shot Peening Machine is complex. It demands careful consideration of the specific needs. While this technology offers many advantages, it also calls for a reflective approach. The challenge lies in balancing cost with performance and quality.

Understanding Shot Peening and Its Principles

Shot peening is a process that enhances the surface of materials. This technique involves bombarding a surface with small spherical media. The results are significant. It can increase fatigue strength by up to 50%, according to a report by the Society of Manufacturing Engineers. This means longer-lasting components in various industries.

Understanding the principles of shot peening helps in setting up the process correctly. It applies compressive stresses to the surface. These stresses can prevent crack formation. Researchers have indicated that a well-controlled peening process reduces the likelihood of failures. However, if not executed properly, it can cause surface defects. The challenge lies in finding the right balance between intensity and coverage.

Many industries utilize this method, from aerospace to automotive. A study found that 70% of companies report improved performance after implementing shot peening. Nevertheless, the cost of machinery and expertise may be barriers for some. Companies must weigh these costs against the potential benefits. The truth is, neglecting surface improvement can lead to more significant issues down the line.

Key Benefits of Using a Shot Peening Machine

Shot peening machines are vital for improving the surface quality of various materials. They enhance fatigue resistance and reduce the risk of failure. This process involves bombarding a surface with small steel balls, called shots. They create a compressive layer that strengthens the material.

Using a shot peening machine offers several key benefits. It significantly increases the lifespan of components. For instance, in aerospace and automotive applications, peened parts show improved performance under stress. This can save costs on replacements over time. Additionally, it enhances surface finishes, which can be critical for specific applications.

Tips: Always ensure proper setup of the machine. Incorrect settings can lead to uneven peening. Regularly check shot size and hardness. This affects the effectiveness of the process. Remember, not all materials react the same way. Experiment with different techniques to find the best results. A little trial and error can lead to excellent improvements.

Applications of Shot Peening in Various Industries

Shot peening is a crucial process in various industries. It enhances the fatigue strength of materials by inducing compressive residual stresses. This improvement is significant in sectors like aerospace and automotive. For instance, research indicates that shot peening can increase component life by over 50%. In the aerospace industry, where safety is paramount, the use of shot peening on turbine blades has led to remarkable performance improvements.

In the automotive sector, shot peening prevents stress-related failures in critical components. The process is often applied to springs, gears, and crankshafts. Reports show that shot peened components can exhibit up to a 70% increase in life expectancy under cyclic loading conditions. However, not all applications benefit equally from shot peening. Some materials do not respond well. This inconsistency raises questions. Are manufacturers effectively utilizing the technique in all possible areas?

In addition to aerospace and automotive, shot peening finds applications in the oil and gas industry. Here, the technique is essential for improving the reliability of equipment subjected to harsh environments. Recent data reveals that shot peening can reduce fracture occurrences by 40% in pipeline components. As industries strive for efficiency, the need to explore and refine shot peening applications becomes vital.

Factors Influencing the Effectiveness of Shot Peening Processes

Shot peening is a vital process for enhancing surface properties. Several factors influence its effectiveness. These include the size and type of shot, peening intensity, and the material of the component. Each element plays a crucial role in achieving desired results.

Using the right shot size can make a big difference. Smaller shots reach tighter areas but may be less effective on larger surfaces. Larger shots provide more impact but can cause surface damage if not controlled. Adjusting the intensity of the process can also affect fatigue strength. Overdoing it can lead to undesirable indentations.

Tips: Always test different shot types before committing to a process. It might help to analyze existing materials for optimal shot selection. Monitor the peening intensity to avoid excessive wear. Understanding these factors will lead to better results in surface improvement. Reflection on past practices can refine your approach.

Home

Equipment

Vacuum Process Casting Molding Line

Automatic Flaskless Sand Molding Production Line

Sand Preparation Automation Line

Shot Blasting Peening Equipment

Stainless Steel Stripe Shot Blasting Machine

Steel Preservation Line

Roller Conveyor Shot Blasting Machine

Hook Type Shot Blasting Machine

Pass Through Monorail Shot Blasting Machine

Mesh Belt Shot Blasting Machine

Rotary Table Shot Blasting Machine

Trolley Type Shot Blasting Machine

Steel Pipe Shot Blasting Machine

Crawler Type Shot Blasting Machine

Rolling Drum Shot Blasting Machine

Automatic Titling Drum Shot Blasting Machine

Portable Shot Blasting Machine

Abrasive Blast Booth And Spray Paint Booth

Enviromental Dust Removal Equipment

Why Xinke

News Room

Blog

Contact Us