7 Essential Tips for Optimizing Your Industrial Shot Blasting Machine Performance

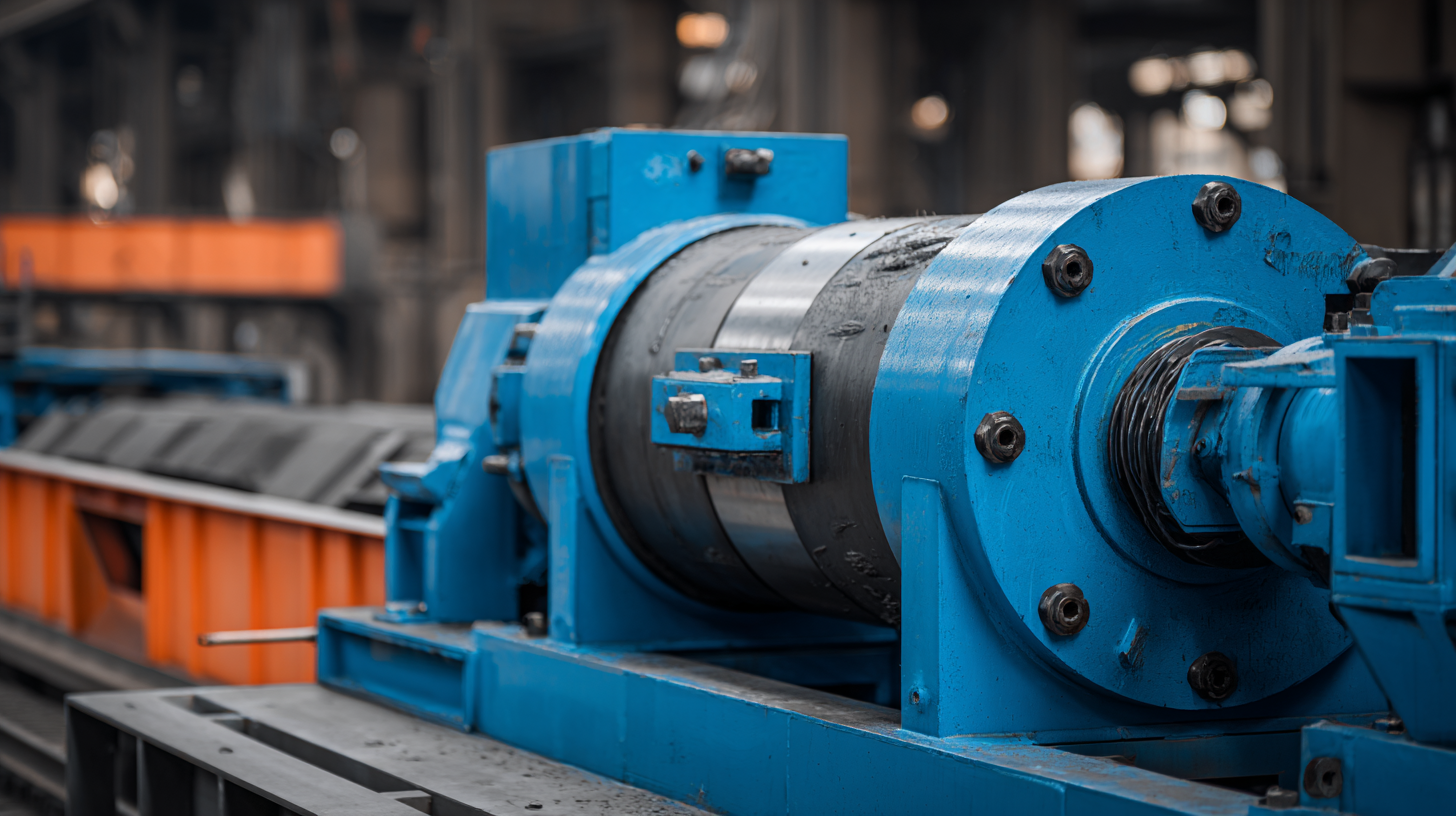

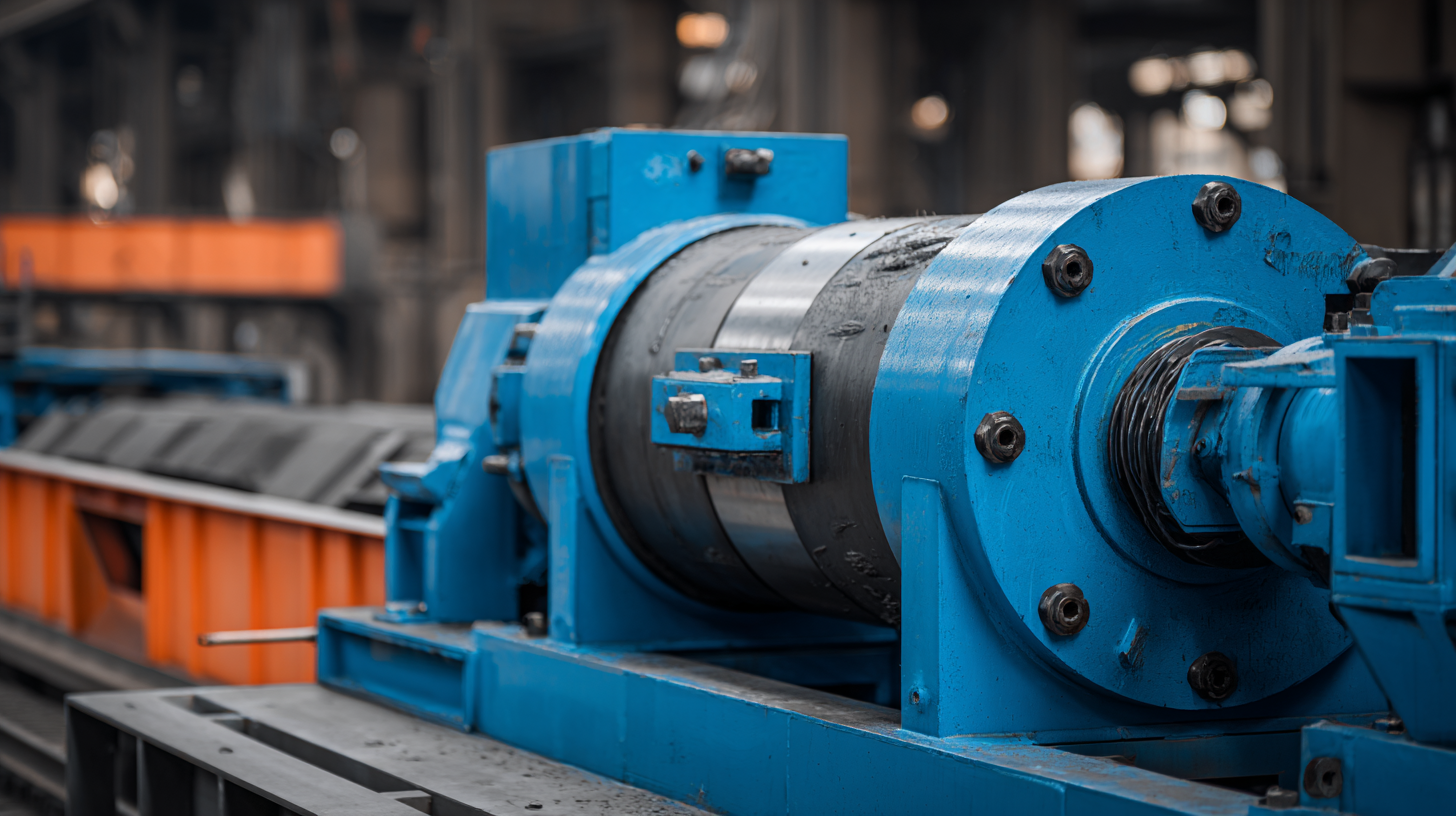

Optimizing the performance of your Industrial Shot Blasting Machine is crucial for enhancing efficiency and achieving high-quality results in your manufacturing processes. This vital equipment plays a significant role in surface preparation, cleaning, and finishing, making it essential to not only understand its functionality but also implement strategies for its optimal operation. In this guide, we will explore seven essential tips that will empower you to maximize the effectiveness of your Industrial Shot Blasting Machine. By addressing factors such as maintenance routines, operational parameters, and the selection of appropriate blasting media, you can ensure that your machine operates at peak performance, ultimately leading to improved productivity and reduced operational costs.

Whether you are new to industrial blasting or looking to refine your existing practices, these insights will provide valuable guidance for achieving optimal results.

Key Factors Impacting Shot Blasting Machine Efficiency and Longevity

Optimizing the efficiency and longevity of your industrial shot blasting machine involves several key factors. First and foremost, the maintenance of the equipment is crucial. Regular inspections and timely repairs can prevent minor issues from escalating into major problems, which could otherwise lead to prolonged downtime and costly repairs. Lubrication of moving parts and cleaning of the equipment after use are also essential practices that ensure smooth operation and prolong the life of the machine.

Another significant factor is the choice of abrasive materials. Using the correct type and size of abrasives can significantly impact the performance of your shot blasting machine. Inappropriate abrasives can lead to faster wear and tear on components, reducing efficiency and increasing maintenance costs. Additionally, optimizing the blast pattern and adjusting the machine's speed to match the specific requirements of the materials being processed can enhance productivity. By focusing on these elements, operators can achieve a greater return on investment and improve the overall performance of their shot blasting operations.

Understanding the Role of Abrasive Materials in Shot Blasting Performance

In shot blasting, the choice of abrasive materials plays a crucial role in determining the efficiency and effectiveness of the machine’s performance. Abrasive materials like steel shots, sand, and glass beads each possess distinct properties that influence the surface finish and cleaning capabilities. For instance, steel shots are typically used for heavy-duty applications due to their durability and ability to withstand repeated impacts, making them ideal for removing rust and scaling from tough metal surfaces. In contrast, softer abrasives like glass beads are used for lighter applications, such as cleaning or preparing surfaces without causing significant damage.

The size and shape of the abrasive also significantly impact the blasting process. Uniformly sized abrasives ensure a consistent surface finish, while angular shapes can enhance the cutting action, increasing cleaning efficiency. Moreover, understanding the wear characteristics of different abrasive materials can help operators optimize their shot blasting machine by selecting the right medium for specific applications and prolonging equipment life. This strategic selection leads to improved performance, reduced maintenance costs, and ultimately, better results in industrial cleaning and surface preparation tasks.

Importance of Regular Maintenance and Calibration for Optimal Operations

Regular maintenance and calibration of industrial shot blasting machines are crucial for ensuring optimal performance and longevity. Over time, wear and tear can lead to decreased efficiency and increased operational costs. By establishing a routine maintenance schedule, operators can identify potential issues before they escalate, thus avoiding unexpected downtime. Activities such as checking the wear components, inspecting the abrasive media, and ensuring proper airflow can significantly contribute to smoother operations.

Calibration is another essential aspect that should not be overlooked. Proper calibration ensures that the machine operates within its designed parameters, optimizing blasting patterns and achieving uniform surface finishes. Regularly calibrating the machine not only enhances productivity but also reduces the risk of material wastage and enhances worker safety. By prioritizing maintenance and calibration, businesses can maximize their investment in shot blasting technology, leading to improved efficiency and higher-quality results.

Analyzing Energy Consumption Patterns to Enhance Cost Efficiency

Analyzing energy consumption patterns is crucial for enhancing cost efficiency in industrial shot blasting operations. By meticulously tracking energy usage, operators can identify peak consumption periods and potential inefficiencies in the system. This analysis allows for informed adjustments in the blasting schedule, optimizing machine operations during off-peak hours when energy costs are lower. Such strategies not only reduce expenses but also extend the lifespan of the equipment by preventing excessive strain during high-energy demand periods.

Another important aspect is the implementation of energy-efficient technologies and practices. Upgrading to variable frequency drives, for instance, can significantly decrease energy consumption while maintaining performance levels. Regular maintenance checks also play a vital role in ensuring that machines operate at optimal efficiency, as worn components can lead to increased energy demands. By fostering a culture of energy awareness and continuous improvement, businesses can achieve substantial cost savings, making energy consumption analysis a key component of successful shot blasting machine management.

Measuring and Improving Surface Finish Quality in Industrial Applications

Achieving optimal surface finish quality in industrial applications is paramount for enhancing the durability and functionality of manufactured components. One effective method to assess surface finish is through the use of profilometers, which provide detailed measurements of surface texture and roughness. By regularly monitoring these parameters, operators can identify deviations from desired specifications, enabling timely adjustments to the shot blasting process. This proactive approach not only improves product quality but also minimizes costly rework.

Furthermore, improving surface finish quality involves optimizing various parameters of the shot blasting machine, such as the type of abrasives used, the blasting pressure, and the machine's operational speed. Selecting the right media specific to the material being processed can significantly affect the outcome. Additionally, fine-tuning the angle and distance of the nozzle from the workpiece ensures a uniform distribution of abrasive particles, which directly influences the surface finish. By systematically analyzing these factors, operators can enhance the efficiency of their shot blasting operations while achieving superior surface finishes that meet stringent industry standards.

7 Essential Tips for Optimizing Your Industrial Shot Blasting Machine Performance - Measuring and Improving Surface Finish Quality in Industrial Applications

| Tip No. |

Optimization Tip |

Expected Improvement (%) |

Surface Finish Quality (Ra, µm) |

Recommended Frequency of Maintenance (months) |

| 1 |

Regularly Replace Blasting Media |

15% |

0.8 |

3 |

| 2 |

Optimize Blast Angle |

20% |

0.6 |

6 |

| 3 |

Adjust Equipment Speed |

10% |

0.5 |

4 |

| 4 |

Monitor Dust Collection System |

5% |

0.7 |

2 |

| 5 |

Maintain Consistent Machine Settings |

18% |

0.4 |

5 |

| 6 |

Use Proper Personal Protective Equipment |

N/A |

N/A |

N/A |

| 7 |

Conduct Regular Training for Operators |

25% |

0.3 |

12 |

Home

Equipment

Vacuum Process Casting Molding Line

Automatic Flaskless Sand Molding Production Line

Sand Preparation Automation Line

Shot Blasting Peening Equipment

Stainless Steel Stripe Shot Blasting Machine

Steel Preservation Line

Roller Conveyor Shot Blasting Machine

Hook Type Shot Blasting Machine

Pass Through Monorail Shot Blasting Machine

Mesh Belt Shot Blasting Machine

Rotary Table Shot Blasting Machine

Trolley Type Shot Blasting Machine

Steel Pipe Shot Blasting Machine

Crawler Type Shot Blasting Machine

Rolling Drum Shot Blasting Machine

Automatic Titling Drum Shot Blasting Machine

Portable Shot Blasting Machine

Abrasive Blast Booth And Spray Paint Booth

Enviromental Dust Removal Equipment

Why Xinke

News Room

Blog

Contact Us