Why Invest in a Sand Shot Blasting Machine for Your Business Productivity

In today's competitive manufacturing landscape, businesses are constantly seeking ways to enhance productivity and efficiency. One of the pivotal advancements in surface preparation technology is the Sand Shot Blasting Machine. This innovative equipment not only improves the quality of finished surfaces but also significantly accelerates production processes. According to industry expert Dr. Michael Anderson, a renowned specialist in surface finishing technology, “Investing in a Sand Shot Blasting Machine is not just a choice; it’s a necessity for businesses that aim to stay ahead in the market.”

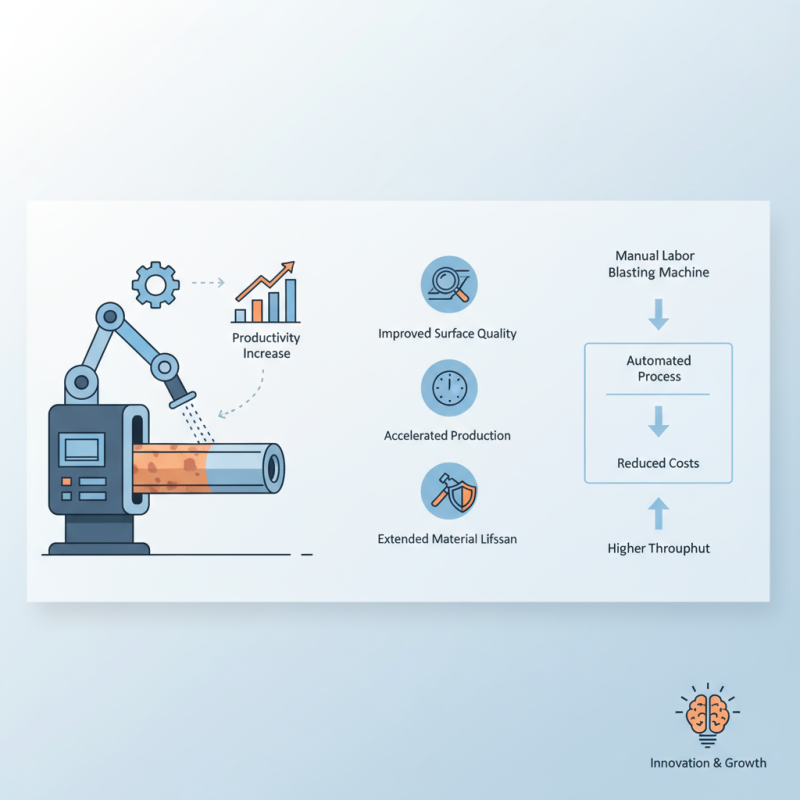

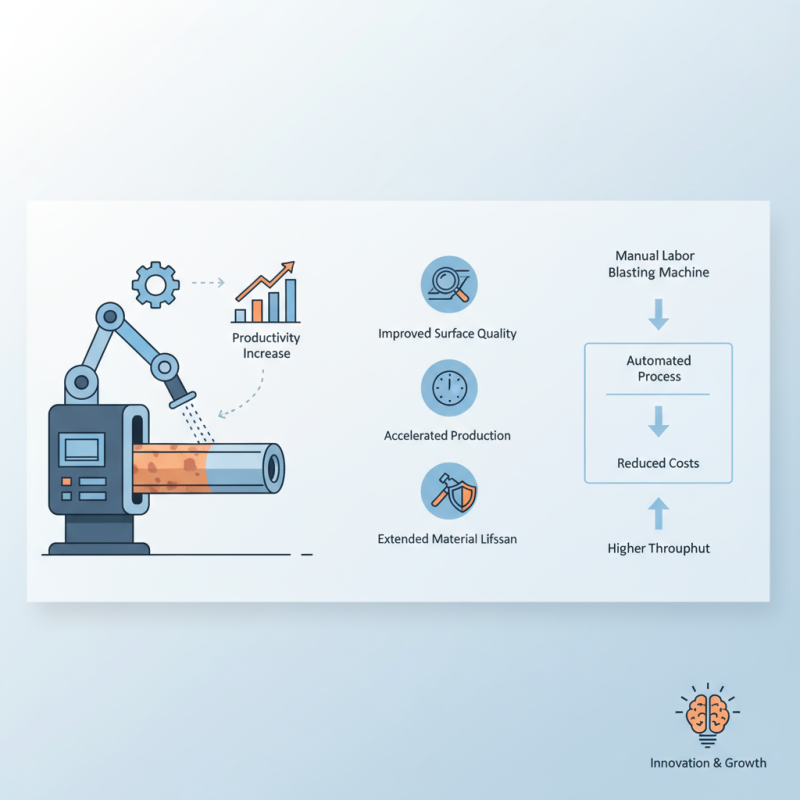

The transformative power of a Sand Shot Blasting Machine lies in its ability to remove imperfections, prepare surfaces for further processing, and extend the lifespan of various materials. As companies strive for operational excellence, integrating advanced machinery becomes crucial. This investment not only maximizes throughput but also reduces labor costs by automating time-consuming tasks. With the endorsement of professionals like Dr. Anderson, it’s clear that the right equipment can propel a business toward greater productivity and sustainability. Thus, embracing technology such as the Sand Shot Blasting Machine is essential for those looking to innovate and grow in an ever-evolving industry.

Benefits of Sand Shot Blasting Machines for Enhanced Efficiency

Investing in a sand shot blasting machine can significantly enhance your business's productivity by streamlining processes and improving surface finishing. One of the primary benefits of these machines is their ability to remove contaminants like rust, old paint, and debris with precision and efficiency. This not only prepares surfaces for further treatment or coating but also ensures a higher quality end product, which is crucial in maintaining competitive advantage in today's market.

Moreover, sand shot blasting machines contribute to time and cost savings. Unlike manual cleaning methods, these machines drastically reduce the time spent on surface preparation. This efficiency allows businesses to allocate labor to other critical processes, maximizing workforce utilization. Additionally, the long-term durability of the blasting machines means less frequent maintenance and replacement costs, further improving the overall return on investment. By enhancing operational efficiency, these machines empower businesses to meet production demands more effectively, leading to greater customer satisfaction and potentially increased revenue.

Productivity Benefits of Sand Shot Blasting Machines

Understanding the Mechanism of Sand Shot Blasting Technology

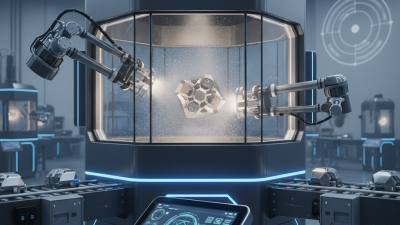

The mechanism of sand shot blasting technology plays a pivotal role in improving business productivity by enhancing surface preparation and finishing in various industrial applications. Sand shot blasting, a process involving the propulsion of abrasive materials at high speeds onto surfaces, is employed to clean, strengthen, and prepare surfaces for further treatment. According to a report by Research and Markets, the global shot blasting machines market was valued at over $420 million in 2021, with projections indicating a compound annual growth rate (CAGR) of approximately 5% from 2022 to 2027. This growth underscores the increasing adoption of sand shot blasting technology across industries.

The efficiency of sand shot blasting technology lies in its ability to produce a uniform surface finish, which is crucial in sectors such as automotive and aerospace manufacturing. The process removes rust, contaminants, and old coatings, thereby increasing the adherence of paints and other treatments. A study published in the Journal of Surface Engineering revealed that components treated with sand blasting experienced a 30-50% improvement in coating adhesion compared to untreated surfaces. Additionally, advancements in automation and precision technology have optimized sand shot blasting systems, reducing operation time and labor costs while enhancing overall efficiency.

Why Invest in a Sand Shot Blasting Machine for Your Business Productivity

| Dimension |

Data |

Notes |

| Applications |

Metal Parts Cleaning, Surface Preparation, Surface Finishing |

Widely used in manufacturing industries |

| Efficiency Boost |

30-50% |

Can significantly speed up production times |

| Cost Savings |

Up to 20% reduction on labor costs |

Lower cleaning and finishing costs |

| Environmental Impact |

Minimized waste generation |

Recyclable materials can be used |

| Machine Lifespan |

10-15 years with maintenance |

Durable and built for heavy use |

Comparative Analysis: Traditional Methods vs. Sand Shot Blasting

When evaluating different surface preparation methods, traditional techniques like manual scraping or chemical cleaning often fall short in terms of efficiency and overall productivity. These methods can be labor-intensive, resulting in increased labor costs and longer project timelines. In contrast, sand shot blasting machines offer a much more efficient solution. They automate the abrasive cleaning process, significantly speeding up the surface preparation, which enhances productivity while lowering labor costs.

One important tip when considering the transition to sand shot blasting is to assess the specific needs of your business operations. Make sure to analyze the types of surfaces you typically work with and the degree of cleanliness required. This will help you choose the right equipment and abrasive material, ensuring optimal performance and surface quality.

Additionally, proper training for your team is crucial to maximize the benefits of sand shot blasting. Familiarizing them with the machine's operation and maintenance will lead to better results and minimize downtime. Investing in regular training sessions can enhance the proficiency and safety of your workforce, ultimately contributing to improved productivity and output quality.

Cost-Benefit Analysis of Investing in Sand Shot Blasting Equipment

Investing in a sand shot blasting machine can significantly enhance business productivity, particularly when analyzed through a cost-benefit lens. The initial capital outlay for this equipment may seem substantial, but it is essential to consider the long-term savings and efficiencies achieved through its use. Sand shot blasting equipment increases surface preparation efficiency, leading to faster project turnaround times. This quick processing helps eliminate bottlenecks in production lines, ultimately reducing labor costs and increasing overall output.

Moreover, the durability and effectiveness of sand shot blasting equipment contribute to improved product quality. By ensuring a perfect surface finish, companies can reduce the need for additional finishing processes, saving both time and materials. Additionally, higher quality products can lead to improved customer satisfaction and potentially higher pricing for finished goods. The return on investment becomes clear when considering these factors in conjunction with enhanced workplace safety, lower downtime, and reduced waste, making the case for investing in sand shot blasting machines strong from a financial perspective.

Applications of Sand Shot Blasting in Various Industries

Sand shot blasting is a versatile process used across various industries to enhance surface preparation and improve product quality. In construction, this technique is essential for cleaning and preparing metal surfaces, ensuring better adhesion of coatings. The construction of buildings, bridges, and infrastructure benefits significantly from sand shot blasting, as it removes contaminants like rust and old paint, leading to longer-lasting structures.

Similarly, the automotive and aerospace industries utilize sand shot blasting for surface finishing. This method is employed to achieve a uniform texture on metal components, such as engine parts and aircraft frames, allowing for improved performance and durability. Furthermore, the process is crucial in the manufacturing of molds used in casting, where a clean surface can lead to more accurate and effective reproduction of designs.

In the realm of manufacturing, sand shot blasting serves an essential role in preparing surfaces for welding and other processes. By creating a clean and roughened surface, the technique enhances the bond strength of welded joints, thus contributing to the overall integrity of the finished product. As industries continue to prioritize quality and efficiency, investing in sand shot blasting machines can significantly boost productivity and ensure superior results across various applications.

Home

Equipment

Vacuum Process Casting Molding Line

Automatic Flaskless Sand Molding Production Line

Sand Preparation Automation Line

Shot Blasting Peening Equipment

Stainless Steel Stripe Shot Blasting Machine

Steel Preservation Line

Roller Conveyor Shot Blasting Machine

Hook Type Shot Blasting Machine

Pass Through Monorail Shot Blasting Machine

Mesh Belt Shot Blasting Machine

Rotary Table Shot Blasting Machine

Trolley Type Shot Blasting Machine

Steel Pipe Shot Blasting Machine

Crawler Type Shot Blasting Machine

Rolling Drum Shot Blasting Machine

Automatic Titling Drum Shot Blasting Machine

Portable Shot Blasting Machine

Abrasive Blast Booth And Spray Paint Booth

Enviromental Dust Removal Equipment

Why Xinke

News Room

Blog

Contact Us