Maximizing Efficiency: How Hanger Shot Blasting Machines Enhance Surface Preparation with 30% Time Savings

In the fast-paced manufacturing industry, efficiency and precision in surface preparation are critical to maintaining a competitive edge. Recent studies indicate that optimized surface preparation techniques can lead to a remarkable increase in production performance, with a potential reduction in processing time by up to 30%. This is particularly evident in the utilization of advanced technologies such as the Hanger Shot Blasting Machine, which has revolutionized traditional methods of surface finishing. According to a comprehensive report from the International Journal of Surface Engineering, the adoption of automated blasting solutions not only enhances throughput but also significantly improves the quality of the finished product.

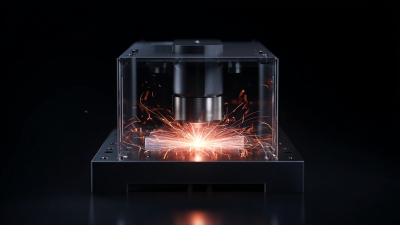

The Hanger Shot Blasting Machine, designed to cater to complex geometries and large components, streamlines the blasting process through a systematic approach that minimizes manual intervention. This efficiency translates into substantial cost savings and shorter lead times, which are crucial for manufacturers aiming for rapid response to market demands. As industries increasingly focus on sustainability and waste reduction, the ability of Hanger Shot Blasting Machines to optimize abrasive use while achieving high cleanliness and uniform surface finish positions them as a vital asset in modern manufacturing operations. Collectively, these benefits underline the profound impact that innovative shot blasting technologies have on elevating production efficiency and quality, paving the way for a more productive future in surface preparation.

The Hanger Shot Blasting Machine, designed to cater to complex geometries and large components, streamlines the blasting process through a systematic approach that minimizes manual intervention. This efficiency translates into substantial cost savings and shorter lead times, which are crucial for manufacturers aiming for rapid response to market demands. As industries increasingly focus on sustainability and waste reduction, the ability of Hanger Shot Blasting Machines to optimize abrasive use while achieving high cleanliness and uniform surface finish positions them as a vital asset in modern manufacturing operations. Collectively, these benefits underline the profound impact that innovative shot blasting technologies have on elevating production efficiency and quality, paving the way for a more productive future in surface preparation.

Benefits of Hanger Shot Blasting Machines for Industrial Applications

Hanger shot blasting machines are revolutionizing surface preparation across various industrial applications by significantly enhancing efficiency and reducing processing times. Recent investments by companies in advanced shot blasting systems have demonstrated a substantial commitment to improving production capabilities. For instance, a notable foundry has transformed its operations with high-volume shotblasting solutions, yielding considerable improvements in both performance and output.

The advantages of incorporating hanger shot blasting machines extend beyond time savings. These systems not only facilitate faster surface treatments but also ensure superior finish quality. By upgrading to modern blast wheel technologies, organizations are seeing their cycle times halved, enabling them to manage higher volumes without compromising on quality. In addition, the introduction of cost-effective machines designed for flexibility means that even smaller operations can benefit from enhanced blast capabilities, making these machines essential investments for boosting overall operational efficiency.

Key Features of Hanger Shot Blasting Technology and Their Impact

Hanger shot blasting technology is revolutionizing surface preparation by significantly enhancing efficiency. One of its key features is the ability to handle multiple components simultaneously, allowing for uniform cleaning and profiling. This not only speeds up the workflow but also reduces labor costs, contributing to time savings of up to 30%. The automation capabilities of these machines ensure consistent quality across batches, minimizing the risk of human error and increasing productivity in various industries.

Additionally, the robust design of hanger shot blasting machines allows for the processing of heavy and complex parts that traditional methods struggle to accommodate. This versatility opens up new opportunities in sectors like automotive and aerospace, where high standards for surface conditions are crucial. As the shot blasting machine market continues to grow, projected to reach USD 2.22 billion by 2032, the impact of such advanced technologies becomes increasingly pivotal, driving both innovation and efficiency in surface preparation processes.

Time Efficiency: How Shot Blasting Machines Reduce Surface Preparation Duration

The shot blasting machine market is witnessing significant growth, with projections indicating an increase from $1.41 billion in 2025 to $2.22 billion by 2032. This translates to a compound annual growth rate (CAGR) of 6.7%, reflecting the rising demand for efficient surface preparation solutions across various industries. Shot blasting machines are becoming essential tools for manufacturers aiming to enhance productivity and reduce project turnaround times.

One of the key advantages of shot blasting machines is their ability to substantially decrease surface preparation duration. By automating the cleaning and finishing process, these machines can save up to 30% in time compared to traditional methods. This efficiency not only accelerates production schedules but also improves the overall quality of surface treatments, making them ideal for sectors such as automotive, aerospace, and construction. As industries continue to prioritize efficiency, the adoption of shot blasting technology is expected to play a critical role in streamlining operations and maximizing output.

Cost Savings Realized through Enhanced Surface Preparation Techniques

The advancement of surface preparation techniques, particularly through the use of innovative machines like hanger shot blasting systems, has garnered attention for delivering significant cost savings. By enhancing the efficiency of surface preparation processes, these machines can reduce the time required by up to 30%. This efficiency not only accelerates production timelines but also decreases operational costs, making it a valuable investment for manufacturers seeking to improve their bottom line.

Moreover, modern surface treatment advancements, such as the use of ceramic blasting media and laser surface texturing, have a profound impact on the strength and durability of adhesive bonded parts. By optimizing surface morphology, manufacturers can achieve better adhesion and performance in their products. The integration of these advanced techniques into manufacturing processes illustrates the broader trend of leveraging technology to confine costs while enhancing product quality, thereby positioning companies for competitive advantage in an increasingly demanding marketplace.

Choosing the Right Hanger Shot Blasting Machine for Your Business Needs

When selecting a hanger shot blasting machine for your business, it’s essential to consider your specific needs and operational workflow. The right machine can significantly enhance surface preparation efficiency, often resulting in time savings of up to 30%. Start by assessing the types of materials you will be working with and the required surface finish. Different machines come with various capabilities that cater to distinct applications—ensure you choose one that aligns with the demands of your projects.

Tips: Always evaluate the machine's production capacity to match your output requirements. Conduct a thorough comparison of features including automation level, maintenance needs, and compatibility with your existing equipment. Additionally, seek out user reviews and case studies to gain insights into real-world performance, which can inform your decision-making process.

Moreover, consider the after-sales support and warranty packages offered by manufacturers. A reliable support system can ensure that your operations run smoothly and help alleviate any downtime caused by maintenance issues. Investing in a hanger shot blasting machine is significant, so equip yourself with as much information as possible to make a well-informed choice.

Home

Equipment

Vacuum Process Casting Molding Line

Automatic Flaskless Sand Molding Production Line

Sand Preparation Automation Line

Shot Blasting Peening Equipment

Stainless Steel Stripe Shot Blasting Machine

Steel Preservation Line

Roller Conveyor Shot Blasting Machine

Hook Type Shot Blasting Machine

Pass Through Monorail Shot Blasting Machine

Mesh Belt Shot Blasting Machine

Rotary Table Shot Blasting Machine

Trolley Type Shot Blasting Machine

Steel Pipe Shot Blasting Machine

Crawler Type Shot Blasting Machine

Rolling Drum Shot Blasting Machine

Automatic Titling Drum Shot Blasting Machine

Portable Shot Blasting Machine

Abrasive Blast Booth And Spray Paint Booth

Enviromental Dust Removal Equipment

Why Xinke

News Room

Blog

Contact Us

The Hanger Shot Blasting Machine, designed to cater to complex geometries and large components, streamlines the blasting process through a systematic approach that minimizes manual intervention. This efficiency translates into substantial cost savings and shorter lead times, which are crucial for manufacturers aiming for rapid response to market demands. As industries increasingly focus on sustainability and waste reduction, the ability of Hanger Shot Blasting Machines to optimize abrasive use while achieving high cleanliness and uniform surface finish positions them as a vital asset in modern manufacturing operations. Collectively, these benefits underline the profound impact that innovative shot blasting technologies have on elevating production efficiency and quality, paving the way for a more productive future in surface preparation.

The Hanger Shot Blasting Machine, designed to cater to complex geometries and large components, streamlines the blasting process through a systematic approach that minimizes manual intervention. This efficiency translates into substantial cost savings and shorter lead times, which are crucial for manufacturers aiming for rapid response to market demands. As industries increasingly focus on sustainability and waste reduction, the ability of Hanger Shot Blasting Machines to optimize abrasive use while achieving high cleanliness and uniform surface finish positions them as a vital asset in modern manufacturing operations. Collectively, these benefits underline the profound impact that innovative shot blasting technologies have on elevating production efficiency and quality, paving the way for a more productive future in surface preparation.