The Ultimate Guide to Rotary Shot Blasting Machine for Effective Surface Preparation

In the ever-evolving landscape of surface preparation technologies, the Rotary Shot Blasting Machine stands out as a leading solution for achieving optimal surface cleanliness and profile. According to a recent industry report by MarketsandMarkets, the global shot blasting equipment market is projected to reach USD 3.1 billion by 2027, growing at a CAGR of 4.5%. This robust growth is driven by the increasing demand for high-quality surface treatments in sectors such as automotive, aerospace, and construction. The efficiency and effectiveness of rotary shot blasting operations play a pivotal role in enhancing surface durability and adhesion, making it an indispensable tool in the manufacturing process.

As industries seek to meet stringent quality standards and improve operational productivity, the Rotary Shot Blasting Machine has gained prominence due to its ability to deliver consistent results. By utilizing high-velocity steel shots, this equipment effectively removes contaminants while preparing surfaces for further treatments like painting or coating. Moreover, insights from the Association for Manufacturing Technology reveal that proper surface preparation can increase paint adhesion by up to 50%, underscoring the importance of employing advanced techniques like rotary shot blasting. In this guide, we will explore the top five advantages of rotary shot blasting machines, highlighting their critical role in modern manufacturing environments.

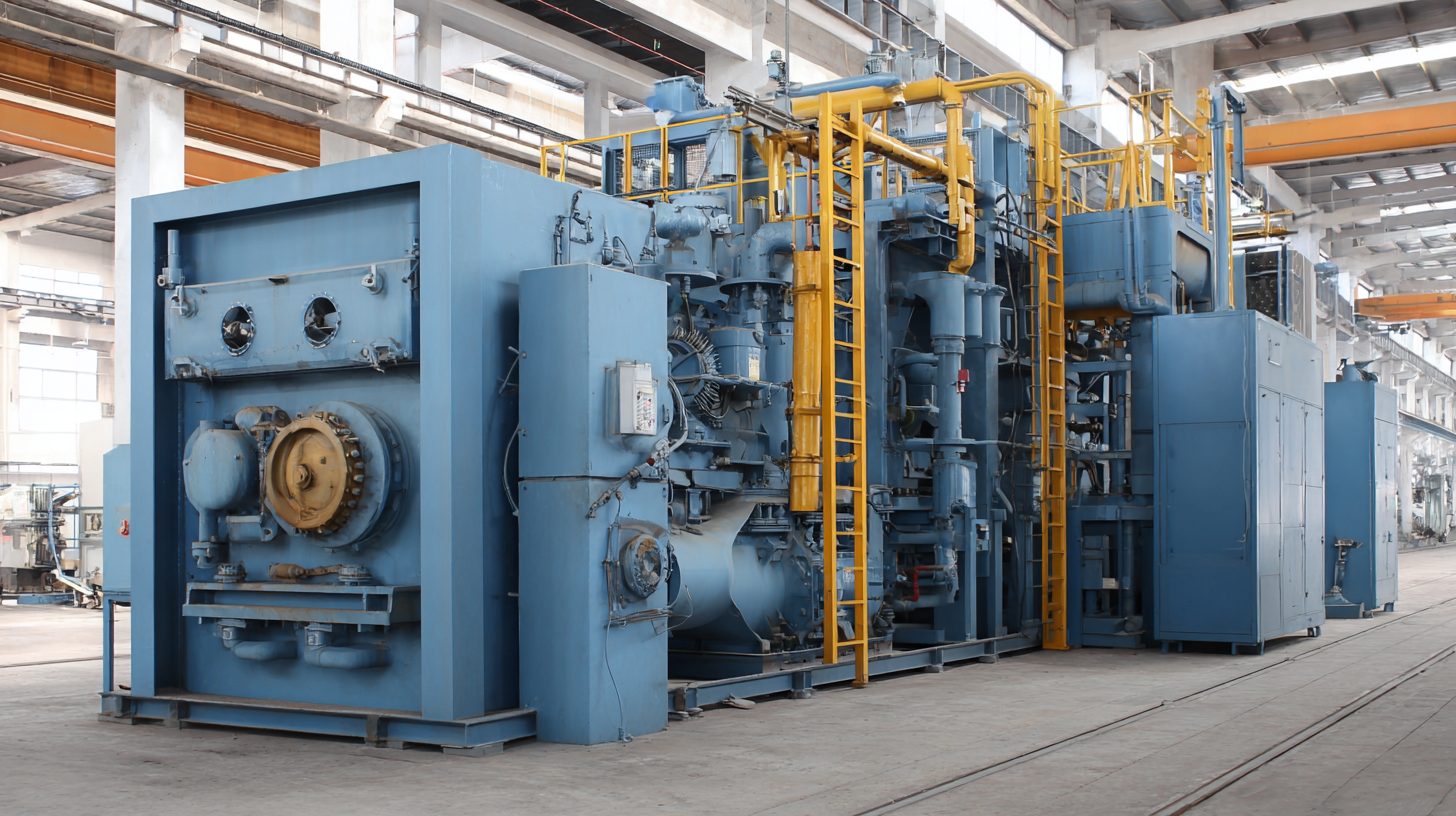

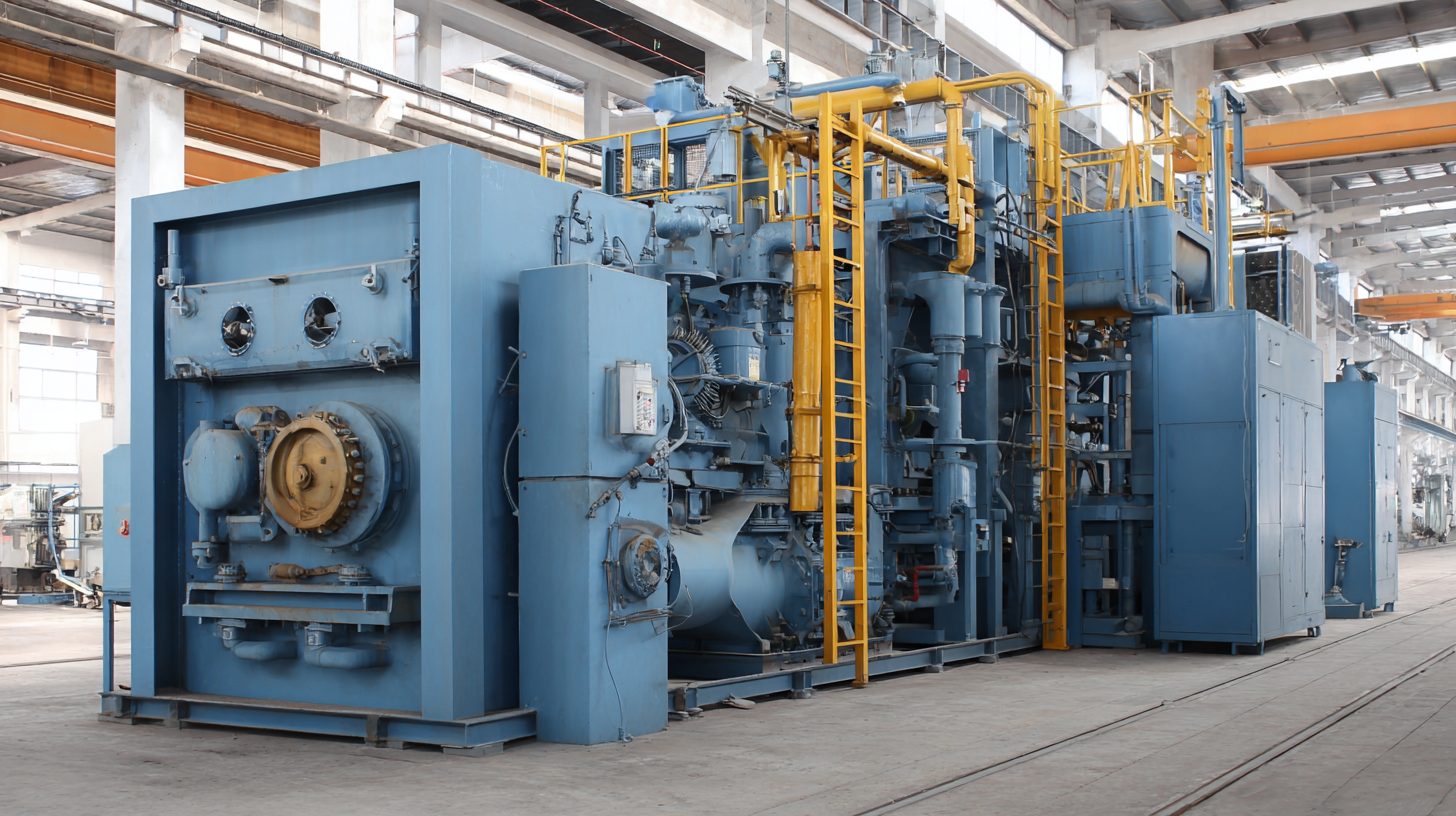

Understanding the Basics of Rotary Shot Blasting Machines

Rotary shot blasting machines are essential tools in the realm of surface preparation, providing an efficient method to clean and finish surfaces. Unlike traditional abrasives like sandblasting, rotary shot blasting utilizes high-velocity steel shots that impact surfaces uniformly to remove contaminants and enhance surface profiles. This method is particularly effective on materials such as metals, concrete, and even certain plastics, making it versatile for various industrial applications. According to industry reports, the global market for shot blasting machines was valued at approximately $350 million in 2021 and is projected to grow steadily due to increased demand for high-quality surface treatments in manufacturing and construction sectors.

Understanding the fundamentals of rotary shot blasting machines involves knowing their core components, including the blast wheel, housing, and control systems. The blast wheel generates the centrifugal force needed to propel the shots, while the housing directs the shots towards the workpiece at adjustable air pressures and volumes. The versatility in media selection corresponding to the specific cleaning requirements allows for optimal results without damaging the substrate. As highlighted in recent industry studies, choosing the right media and operating parameters significantly influences the quality of the finishing process, emphasizing the importance of mastery in rotary shot blasting techniques for effective surface preparation.

The Effectiveness of Rotary Shot Blasting Machines in Surface Preparation

This bar chart illustrates the effectiveness of different surface preparation methods, highlighting the benefits of rotary shot blasting in comparison to other techniques.

Key Features to Look for in Quality Shot Blasting Equipment

When selecting a quality rotary shot blasting machine, understanding key features is paramount for effective surface preparation. The shot blasting equipment market is anticipated to witness significant growth, with a projection of reaching $2.22 billion by 2032 from $1.41 billion in 2025, reflecting a compound annual growth rate (CAGR) of 6.7%. This uptick emphasizes the increasing demand for efficient and reliable surface preparation solutions across various industries.

One critical feature to look for is the integration of heavy-duty vacuum systems, which significantly enhance workplace safety by eliminating hazardous dust and debris. Notably, replacing manual removal of steel shot with vacuum systems can reduce unscheduled downtime by up to 80% and lower manpower requirements by more than 50%. Additionally, simulation software for shot blasting machines is becoming essential in the planning phases. Such software allows for the optimization of the blasting process by simulating every physical stage, ensuring that the equipment meets specific operational needs efficiently. These advancements in technology not only improve productivity but also enhance the overall efficacy of surface preparation processes.

Top 10 Applications of Rotary Shot Blasting in Surface Preparation

Rotary shot blasting is a highly effective method for surface preparation, boasting a variety of applications that make it essential across multiple industries. One of the top applications is concrete floor preparation, where shot blasting efficiently removes surface contaminants, allows for better adhesion of coatings, and provides a rough texture for improved grip. This process is crucial in spaces that require durability and safety, such as warehouses and manufacturing plants.

Another significant application is the cleaning of steel surfaces before coating or painting. The shot blasting process effectively removes rust, mill scale, and other impurities, ensuring a clean substrate that promotes optimum bonding of protective coatings. This is particularly important in industries such as construction and shipbuilding, where the longevity of metal components is paramount. Additionally, rotary shot blasting is commonly used in refurbishing old surfaces, rejuvenating them for new finishes and extending their lifespan. The versatility and efficiency of rotary shot blasting machines are driving their market growth, projected to reach $2.22 billion by 2032, signifying the growing importance of effective surface preparation techniques in various sectors.

The Ultimate Guide to Rotary Shot Blasting Machine for Effective Surface Preparation - Top 10 Applications of Rotary Shot Blasting in Surface Preparation

| Application |

Description |

Benefits |

Industries |

| Steel Surface Preparation |

Cleans and profiles steel surfaces prior to painting or coating. |

Improved adhesion of paints, extended lifecycle of coatings. |

Construction, Shipbuilding |

| Concrete Surface Cleaning |

Removes contaminants and roughens concrete for better bonding. |

Prepares surfaces for adhesives and sealants. |

Construction, Maintenance |

| Foundry Casting Cleaning |

Removes sand and oxide from foundry castings. |

Enhances surface finish of castings. |

Metal Casting |

| Rust Removal |

Effectively strips rust from various metal surfaces. |

Prepares surfaces for further treatment. |

Marine, Automotive |

| Surface Texturing |

Creates textured surfaces for better grip or aesthetic purposes. |

Improved functionality and design appeal. |

Aerospace, Defense |

| Restoration of Machinery |

Cleans and repairs machinery surfaces. |

Prolongs machine life and performance. |

Manufacturing, Heavy Equipment |

| Surface Preparation for Adhesives |

Prepares surfaces for optimal adhesive bonding. |

Ensures strong and reliable bonding. |

Electronics, Automotive |

| De-coating |

Removes old coatings and paint from surfaces. |

Facilitates surface restoration. |

Construction, Restoration |

| Recycling of Metal Components |

Cleans and prepares scrap metal for recycling. |

Increases quality of recycled metals. |

Recycling, Metalworks |

| Preparation for Protective Coatings |

Prepares surfaces for applying protective coatings. |

Enhances longevity of protective layers. |

Industrial, Transportation |

Maintenance Tips for Longevity of Rotary Shot Blasting Machines

Proper maintenance of rotary shot blasting machines is crucial for ensuring their longevity and efficiency in surface preparation tasks. Regular inspection and cleaning are essential to prevent the accumulation of dust and debris that can hinder performance. Checking and replacing worn parts, such as hoses or nozzles, can significantly extend the life of the machinery. It's important to follow the manufacturer's guidelines for maintenance schedules and to ensure that all equipment is operated within the recommended parameters.

Additionally, implementing proper safety procedures while using these machines cannot be overstated. Operators should be equipped with appropriate safety gear to protect against the potential hazards associated with abrasive blasting. These precautions help minimize the risk of injuries and ensure that the equipment operates safely and effectively. By adhering to maintenance and safety tips, users can maximize the performance and durability of rotary shot blasting machines, thereby enhancing overall efficiency in surface preparation tasks.

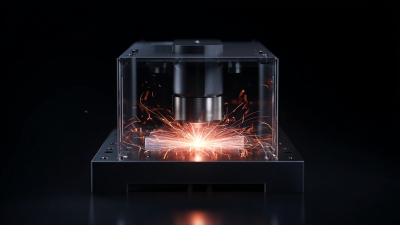

Comparing Rotary Shot Blasting with Other Surface Preparation Techniques

Rotary shot blasting is emerging as a preferred method for surface preparation due to its efficiency and effectiveness compared to traditional techniques such as hand sanding, chemical stripping, and grinding. This method utilizes centrifugal force to propel abrasive materials against a surface, resulting in a clean, uniform finish that is particularly beneficial for large-scale projects. The consistent surface tempering achieved with rotary shot blasting ensures better adhesion for coatings, making it a popular choice in industries such as aerospace, construction, and automotive.

Meanwhile, alternative techniques like laser cleaning are gaining traction due to their environmentally friendly approach and ability to handle delicate surfaces without wear. Laser cleaning offers a high level of precision and can effectively remove contaminants without abrasive impact, presenting a significant advantage for applications that require high-quality surface preparation. As the market for abrasive blasting equipment continues to expand, driven by innovations in both rotary shot blasting and laser technologies, businesses are increasingly evaluating their options to determine the most suitable method for their specific needs.

Home

Equipment

Vacuum Process Casting Molding Line

Automatic Flaskless Sand Molding Production Line

Sand Preparation Automation Line

Shot Blasting Peening Equipment

Stainless Steel Stripe Shot Blasting Machine

Steel Preservation Line

Roller Conveyor Shot Blasting Machine

Hook Type Shot Blasting Machine

Pass Through Monorail Shot Blasting Machine

Mesh Belt Shot Blasting Machine

Rotary Table Shot Blasting Machine

Trolley Type Shot Blasting Machine

Steel Pipe Shot Blasting Machine

Crawler Type Shot Blasting Machine

Rolling Drum Shot Blasting Machine

Automatic Titling Drum Shot Blasting Machine

Portable Shot Blasting Machine

Abrasive Blast Booth And Spray Paint Booth

Enviromental Dust Removal Equipment

Why Xinke

News Room

Blog

Contact Us