Exploring Industry Trends: Rotary Shot Blasting Machines at the 2025 China Import and Export Fair

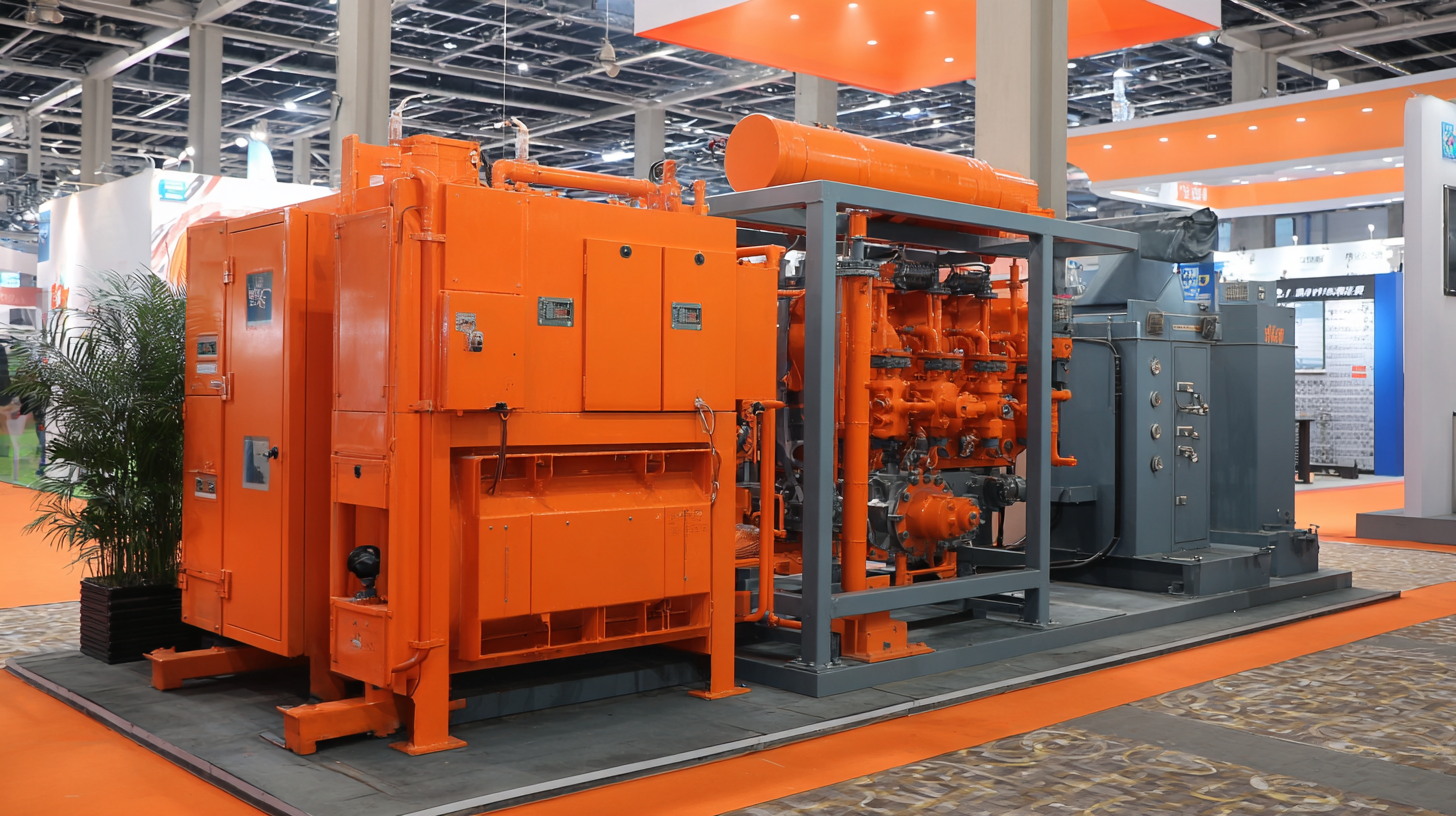

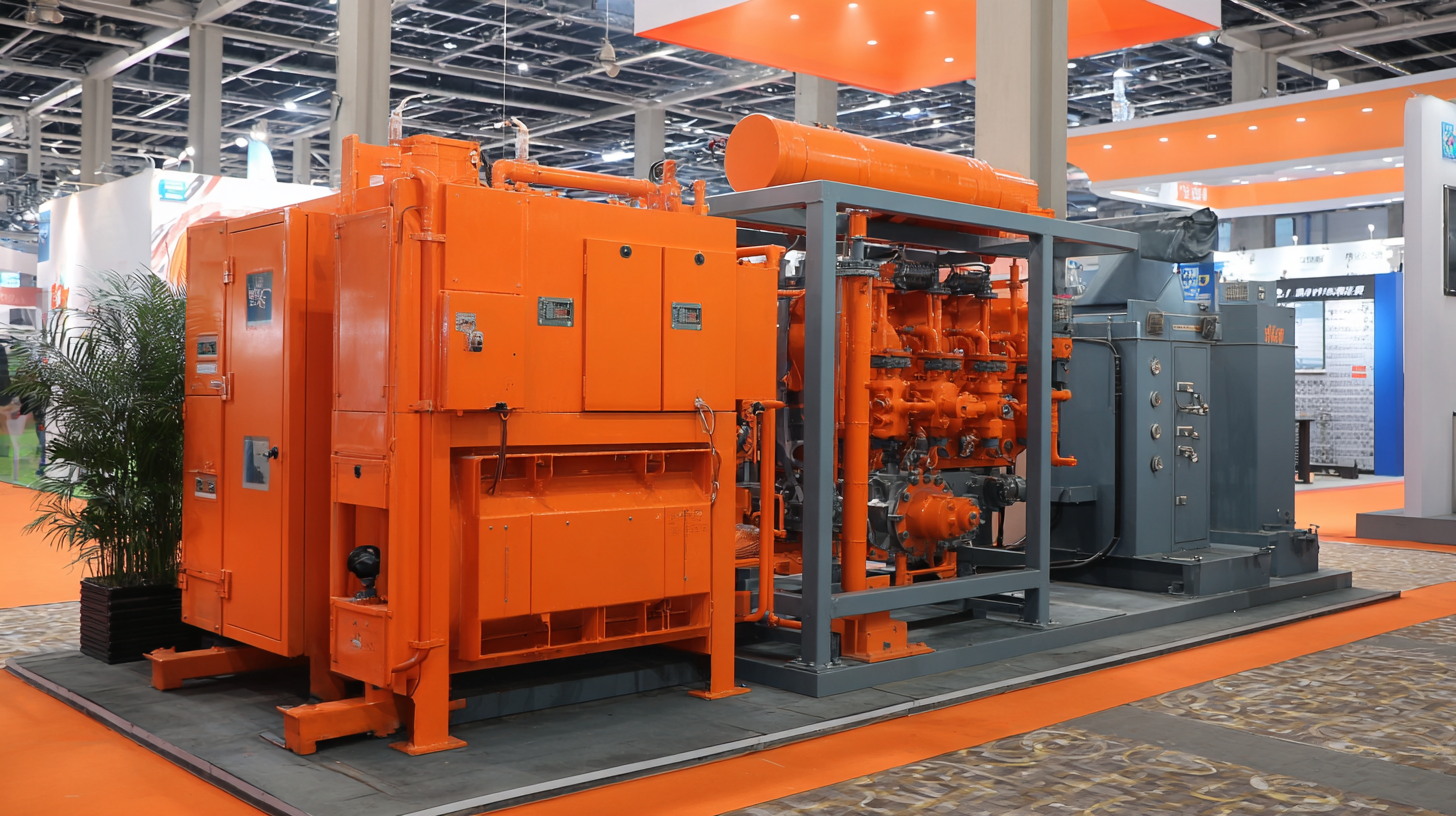

As industries continue to evolve, the significance of advanced machinery becomes increasingly prominent, particularly in sectors requiring precision and efficiency. At the 2025 China Import and Export Fair, or the 138th Canton Fair, one of the standout innovations on display will be the Rotary Shot Blasting Machine. This state-of-the-art equipment plays a crucial role in surface preparation and cleaning, enhancing the quality and longevity of various materials. The fair will serve as a pivotal platform where manufacturers and suppliers from around the globe converge to showcase the latest trends and technologies. Visitors will gain valuable insights into how Rotary Shot Blasting Machines are being integrated into modern manufacturing processes, driving productivity and fostering competitive advantage in an ever-changing market landscape. This exhibition not only highlights the capabilities of these machines but also underscores their importance in meeting the increasing demands of quality and efficiency in production lines across diverse industries.

Current Innovations in Rotary Shot Blasting Technology at the 2025 China Import and Export Fair

As the 2025 China Import and Export Fair approaches, the focus on innovations in rotary shot blasting technology is set to redefine industry standards. Recent industry reports indicate that the global shot blasting equipment market is projected to reach $1.5 billion by 2026, growing at a compound annual growth rate (CAGR) of 4.8% from 2021. This growth is attributed to advancements in automation and efficiency, with rotary shot blasting machines leading the charge due to their effectiveness in surface preparation and finishing.

At this year's fair, several key innovations are expected to be highlighted. For instance, the integration of smart technology in rotary shot blasting machines allows for real-time monitoring and control, optimizing the blasting process while reducing material waste. New designs featuring improved dust collection systems can potentially minimize environmental impact, aligning with global sustainability trends. Furthermore, the advent of more durable materials in machine construction enhances longevity and reduces maintenance costs, making these machines a preferred choice for manufacturers aiming to streamline operations in an increasingly competitive market.

Exploring Industry Trends: Rotary Shot Blasting Machines at the 2025 China Import and Export Fair

| Feature |

Description |

Technical Specifications |

Market Trends |

Innovations |

| Energy Efficiency |

Improved energy consumption rates |

Up to 30% reduction in power usage |

Growing demand for green technologies |

Integration of smart energy systems |

| Automation |

Increased automation capabilities |

Robotic loading and unloading |

Rise of Industry 4.0 practices |

AI-driven operational adjustments |

| Dust Control |

Enhanced dust and emissions management |

High-efficiency particulate air (HEPA) filters |

Regulatory pressures for cleaner production |

Advanced filtration technologies |

| Surface Finishing |

Improved surface finishing techniques |

Achieving finer surface textures |

Demand for high-quality finishes in various industries |

Revolutionary abrasive materials |

| Operator Safety |

Improved safety features during operations |

Protective enclosures and alert systems |

Increasing focus on workplace safety regulations |

Smart monitoring solutions for hazard detection |

Key Industry Players Showcasing Rotary Shot Blasting Machines

The 2025 China Import and Export Fair will serve as a pivotal platform for industry leaders to showcase their latest innovations in rotary shot blasting machines, reflecting a significant trend towards advanced surface treatment technologies. As manufacturers seek to enhance production efficiency and product durability, the emphasis on rotary shot blasting machines is expected to grow. These machines not only improve the finishing processes but also play a crucial role in industries such as automotive, aerospace, and construction, where high-quality surface standards are paramount.

Key industry players are preparing to present their state-of-the-art rotary shot blasting solutions, illustrating how they are addressing the evolving demands of the market. With increasing market competition, the focus on sustainability and reducing operational costs is driving innovation. The showcased technologies will likely highlight improvements in energy efficiency and reduced material waste, aligning with global trends towards sustainable manufacturing practices. This event is anticipated to bring together experts and businesses, fostering collaboration and the exchange of ideas that will shape the future of the rotary shot blasting machinery market.

Market Trends and Predictions for Rotary Shot Blasting Equipment Beyond 2025

The market for rotary shot blasting machines is poised for significant growth in the coming years, with projections indicating an increase from $1.41 billion in 2025 to $2.22 billion by 2032. This growth represents a compound annual growth rate (CAGR) of 6.7%, driven by rising demand across various industries such as automotive, aerospace, and metal fabrication. As manufacturers seek to enhance efficiency and surface preparation processes, the adoption of rotary shot blasting technology is expected to surge.

Furthermore, advancements in technology are contributing to this upward trend. Innovations in automation and smart machinery are making these systems more effective and user-friendly. Additionally, increasing emphasis on environmental sustainability is prompting manufacturers to adopt eco-friendly shot blasting solutions, further expanding market opportunities. The 2025 China Import and Export Fair will serve as a crucial platform to showcase these trends, with manufacturers and industries keen on leveraging rotary shot blasting machines for their operational benefits.

Comparative Analysis of Rotary Shot Blasting Machines Featured at the Fair

The 2025 China Import and Export Fair is set to showcase a wide array of rotary shot blasting machines, highlighting the latest innovations and trends within the industry. These machines play a vital role in surface preparation and finishing processes across various sectors, ensuring parts are free from defects and ready for further processing. This year's exhibition promises to feature an in-depth comparative analysis of different models, focusing on performance, efficiency, and cost-effectiveness to help businesses make informed decisions.

When evaluating rotary shot blasting machines at the fair, consider these essential tips: First, assess the machine's capacity and versatility, ensuring it can handle the specific materials and sizes your business requires. Pay close attention to energy consumption and maintenance needs, as these factors can significantly affect long-term operating costs. Lastly, leverage the opportunity to engage with manufacturers and industry experts on-site for insights into the latest technological advancements that could enhance your production processes.

Sustainability and Efficiency: The Future of Shot Blasting in Manufacturing

The future of manufacturing is increasingly leaning towards sustainability and efficiency, with rotary shot blasting machines playing a pivotal role in this transformation. A recent industry report indicates that the global shot blasting equipment market is projected to reach $4.5 billion by 2027, growing at a compound annual growth rate (CAGR) of 6.1%. This growth is fueled by the rising demand for eco-friendly surface treatment solutions that minimize waste and energy consumption.

Innovations in rotary shot blasting technology are helping manufacturers improve operational efficiency while reducing their environmental footprint. According to studies, modern shot blasting machines consume up to 30% less energy compared to traditional models, contributing to lower operating costs and enhanced productivity. Moreover, the integration of advanced automation and control systems ensures a precise and consistent cleaning process, which not only extends the life of the equipment but also optimizes material usage, thereby supporting manufacturers in their sustainable production goals. The focus on sustainability is not just a trend; it’s becoming a necessity as businesses strive to meet regulatory requirements and consumer expectations for greener practices.

Exploring Industry Trends: Rotary Shot Blasting Machines at the 2025 China Import and Export Fair

This bar chart compares key efficiency metrics between the rotary shot blasting machines industry averages from the years 2020 and 2025. The metrics include energy consumption, waste production, recycling rate, and operating cost, demonstrating trends towards greater sustainability and efficiency in manufacturing practices.

Home

Equipment

Vacuum Process Casting Molding Line

Automatic Flaskless Sand Molding Production Line

Sand Preparation Automation Line

Shot Blasting Peening Equipment

Stainless Steel Stripe Shot Blasting Machine

Steel Preservation Line

Roller Conveyor Shot Blasting Machine

Hook Type Shot Blasting Machine

Pass Through Monorail Shot Blasting Machine

Mesh Belt Shot Blasting Machine

Rotary Table Shot Blasting Machine

Trolley Type Shot Blasting Machine

Steel Pipe Shot Blasting Machine

Crawler Type Shot Blasting Machine

Rolling Drum Shot Blasting Machine

Automatic Titling Drum Shot Blasting Machine

Portable Shot Blasting Machine

Abrasive Blast Booth And Spray Paint Booth

Enviromental Dust Removal Equipment

Why Xinke

News Room

Blog

Contact Us