What is a Shot Blasting Machine and How Does It Work?

In the industrial world, a Shot Blasting Machine plays a crucial role in surface preparation. Experts like John Smith, a leader in surface finishing technology, emphasize, “Efficiency and precision are the heart of shot blasting.” This machine uses high-velocity shots to clean or strengthen materials, ensuring they meet quality standards.

Shot blasting is important for various industries, including automotive and construction. By removing contaminants, it improves surface bonding and durability. However, it's essential to consider the operator's safety and the machine's maintenance. Regular downtime for upkeep can be frustrating yet necessary for optimal performance.

While a Shot Blasting Machine offers great benefits, not every application is straightforward. In some cases, improper settings could lead to surface damage. Understanding the machine's capabilities and limitations is key. As the industry evolves, so does the technology, challenging users to adapt and innovate continuously.

What is a Shot Blasting Machine?

A shot blasting machine is an industrial tool used for surface preparation. It employs high-pressure air to propel abrasive materials against surfaces. This process cleans, strengthens, and improves the finish of various materials, such as metal and concrete.

Inside the machine, an abrasive medium, like steel shots or sand, is stored and used to propel against the workpiece. The impact removes rust, scale, and coatings. Operators often adjust the speed and angle of the shots for efficiency. However, this adjustment can be tricky. Finding the right balance between effectiveness and surface damage requires practice.

The versatility of shot blasting machines is remarkable. They can clean small parts and large structural components. Yet, despite their benefits, there are challenges. Overuse can lead to surface erosion. Some operators may rush the process, risking quality. It’s essential to reflect on each shot blasting session to ensure the desired results are achieved.

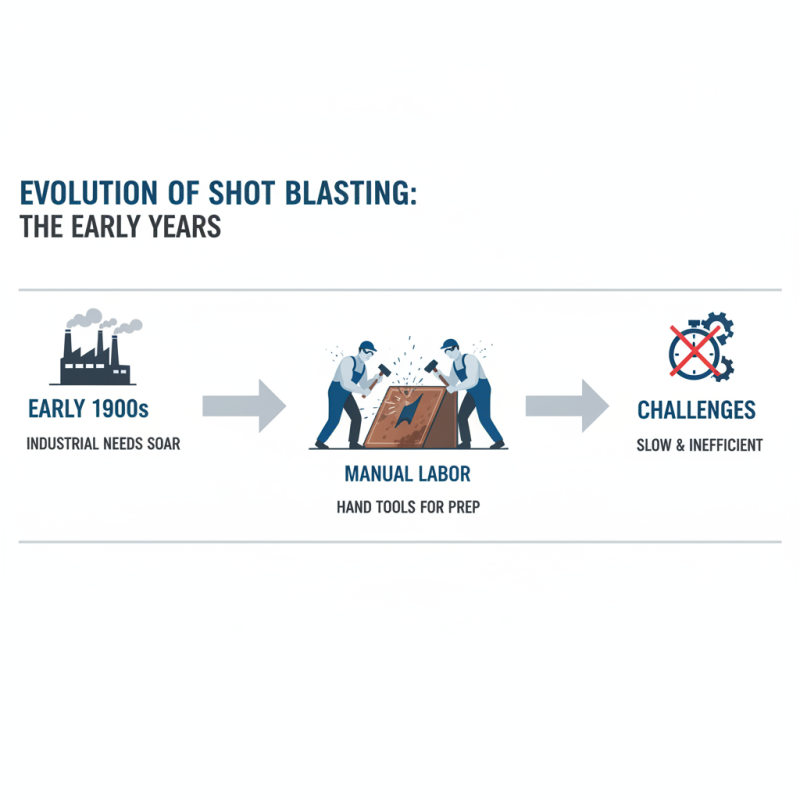

The History and Evolution of Shot Blasting Technology

The history of shot blasting technology is intriguing. It dates back to the early 20th century, when industrial needs skyrocketed. Initially, it involved simple manual systems. Laborers used hand tools to remove rust and prepare surfaces. This was time-consuming and inefficient.

Over the decades, advancements transformed shot blasting. The introduction of machines revolutionized the process. By the 1930s, automated shot blasting systems became more common. They increased productivity dramatically. According to a recent industry report, machinery efficiency improved by 50% compared to manual methods. Still, challenges remained. Some machines had issues with uneven blasting. This inconsistency sometimes led to surface imperfections, requiring additional work.

The evolution did not stop there. In the 1970s, the focus shifted to environmental concerns. Companies began to adopt closed-loop systems to manage waste. Reports show that these systems reduced dust emissions by up to 90%. Despite this progress, many businesses still struggle with maintenance and operational costs. They need strategies to optimize their operations while ensuring quality. The journey of shot blasting technology reflects both innovation and ongoing challenges.

How Shot Blasting Machines Operate: Key Components and Mechanisms

Shot blasting machines are essential in

surface preparation. They use a powerful method to clean and

finish various materials. The main components include a blasting chamber,

a hopper, and the blasting wheel. The blasting chamber contains the material being treated, ensuring

that it receives even exposure to the shot media.

The operation begins with the hopper feeding small abrasive particles into the blasting wheel. The

wheel accelerates these particles, launching them at high speed towards the surface. This impact

removes impurities, rust, and old coatings.

Observing the process can be fascinating. However, it requires careful monitoring to avoid

damage to delicate surfaces.

The key mechanism is the regulation of media flow and impact speed. Improper settings can lead to

uneven surfaces, which is not desirable.

Regular maintenance is crucial. It helps prevent wear and ensures optimal performance. Operators

must remain vigilant. Small discrepancies in media choice or wheel speed can cause

significant issues.

Applications of Shot Blasting Machines in Various Industries

Shot blasting machines have diverse applications across various industries. In the automotive sector, they are used for cleaning and preparing metal surfaces. This process enhances paint adhesion and prevents corrosion. Parts like engine blocks and chassis benefit greatly from this treatment. A proper surface helps improve durability and longevity.

In construction and manufacturing, shot blasting plays a crucial role in surface finishing. Steel beams and plates undergo treatment to remove rust and contaminants. This process ensures a stronger bond with protective coatings. It can be a messy job; debris can scatter in all directions. Operators need to be vigilant and ensure safety protocols are followed.

While shot blasting is effective, it’s not without challenges. Operators must regularly maintain equipment to avoid wear and tear. Dust and noise can be problematic, impacting work environments. Regular training is essential for ensuring users are aware of potential issues. Proper planning can lead to a smoother operation and better results.

Advantages and Limitations of Using Shot Blasting Machines

Shot blasting machines are effective tools for surface preparation. They use high-velocity steel shots to remove contaminants, rust, or old paint from different surfaces. This process enhances the metal’s adherence to finishes or coatings. However, the benefits come with certain limitations.

One significant advantage is the efficiency of shot blasting. It can cover large areas quickly, saving time. The process also produces a smooth surface, ideal for painting or coating. The removal of impurities improves the quality of finished products. However, the noise level can be high during operation. Workers need proper hearing protection, which adds to safety concerns.

Another limitation is equipment maintenance. Shot blasting machines require regular upkeep. Abrasives can cause wear and tear, leading to downtime. Operating these machines heavily relies on skilled personnel. Training is necessary to handle them correctly. Without trained staff, the risk of inefficiency and accidents increases.

What is a Shot Blasting Machine and How Does It Work? - Advantages and Limitations

| Dimension |

Description |

| Type of Shot |

Steel shot, glass beads, aluminum oxide |

| Common Applications |

Cleaning, surface preparation, deburring |

| Advantages |

Efficient cleaning, improved surface finish, increased adhesion |

| Limitations |

Dust generation, material fatigue, limited to certain materials |

| Safety Measures |

Use of PPE, proper ventilation, dust control systems |

| Maintenance |

Regular inspection, cleaning of chambers, replacement of worn parts |

Home

Equipment

Vacuum Process Casting Molding Line

Automatic Flaskless Sand Molding Production Line

Sand Preparation Automation Line

Shot Blasting Peening Equipment

Stainless Steel Stripe Shot Blasting Machine

Steel Preservation Line

Roller Conveyor Shot Blasting Machine

Hook Type Shot Blasting Machine

Pass Through Monorail Shot Blasting Machine

Mesh Belt Shot Blasting Machine

Rotary Table Shot Blasting Machine

Trolley Type Shot Blasting Machine

Steel Pipe Shot Blasting Machine

Crawler Type Shot Blasting Machine

Rolling Drum Shot Blasting Machine

Automatic Titling Drum Shot Blasting Machine

Portable Shot Blasting Machine

Abrasive Blast Booth And Spray Paint Booth

Enviromental Dust Removal Equipment

Why Xinke

News Room

Blog

Contact Us