Exploring How Shot Peening Machines Enhance Component Longevity by up to 50 Percent

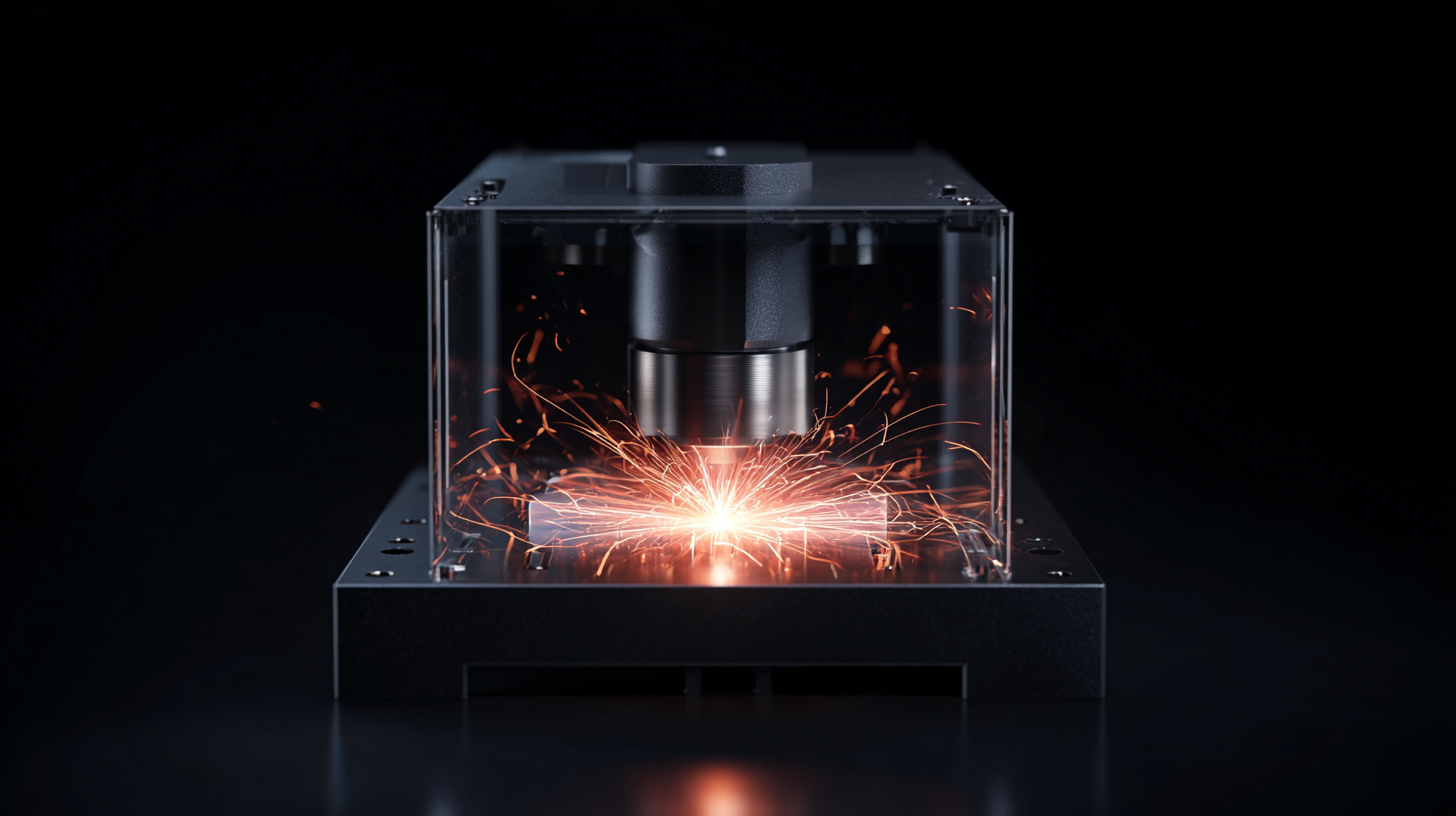

The increasing demand for higher performance and durability in engineering components has propelled the development of advanced manufacturing techniques. Among these, the Shot Peening Machine stands out as a crucial technology that significantly enhances component longevity. By employing high-velocity shot particles to induce compressive stresses on the surface of materials, shot peening not only mitigates the risk of fatigue failure but also enhances resistance to corrosion and wear. Recent studies highlight that components treated with shot peening can experience longevity improvements of up to 50 percent, making it an essential process in industries ranging from aerospace to automotive.

This exploration aims to delve into the intricacies of shot peening, elucidating its mechanisms, benefits, and the transformative impact it has on modern manufacturing and maintenance practices, ultimately driving innovation and cost-effectiveness across various sectors.

How Shot Peening Machines Improve Fatigue Resistance in Metal Components

Shot peening is a crucial process employed to enhance the fatigue resistance of metal components, particularly in industries demanding high-performance materials. By bombarding a surface with small spherical media, this technique induces compressive residual stresses within the material. These compressive stresses counteract the tensile stresses that typically lead to crack initiation and propagation under cyclic loading, effectively increasing the component's lifespan.

Furthermore, the process not only improves fatigue resistance but also induces a favorable surface roughness, contributing to better wear resistance. The microscopic indentations created during shot peening enhance the surface's ability to distribute stress more evenly, thereby minimizing points of weakness. As a result, components subjected to rigorous operational conditions exhibit remarkable improvements in durability, showing enhancements in longevity by up to 50 percent. This is particularly significant for industries such as aerospace, automotive, and manufacturing, where the reliability and performance of metal parts are critical for operational success.

The Mechanisms Behind Shot Peening and Their Impact on Component Durability

Shot peening is a surface treatment technique that significantly enhances the durability of components by inducing compressive residual stress in the material. The process involves bombarding the surface with small spherical media, known as shots, which creates a series of plastic deformations. These deformations improve fatigue resistance and help to prevent crack propagation, ultimately leading to a remarkable increase in the lifespan of various engineering components. The underlying mechanism hinges on the creation of a toughened surface layer, which can withstand mechanical stresses more effectively than untreated surfaces.

**Tips for Effective Shot Peening:**

1. **Choose the Right Media:** Selecting the appropriate size and hardness of shot is critical. Larger shots impart more stress but may damage delicate components, while finer shots are suited for more intricate parts.

2. **Optimize Peening Parameters:** Adjusting parameters like intensity, coverage, and time can enhance the peening effect. It's essential to balance these factors to achieve the desired level of surface treatment without overdoing it.

By understanding the mechanics of shot peening and its impact on component longevity, manufacturers can make informed choices that lead to improved performance and reliability in their products. The benefits extend beyond merely extending life; they also enhance overall system performance by reducing maintenance costs and downtime.

Quantifying Component Longevity: Up to 50% Improvement through Shot Peening

Shot peening is a process that significantly enhances the longevity of mechanical components, achieving improvements of up to 50%. This technique involves bombarding a surface with numerous small spherical pellets (shots) to induce compressive residual stress and improve fatigue resistance. As a result, components subjected to shot peening can withstand greater loads and endure harsher operating conditions, leading to a remarkable increase in their lifespan.

Shot peening is a process that significantly enhances the longevity of mechanical components, achieving improvements of up to 50%. This technique involves bombarding a surface with numerous small spherical pellets (shots) to induce compressive residual stress and improve fatigue resistance. As a result, components subjected to shot peening can withstand greater loads and endure harsher operating conditions, leading to a remarkable increase in their lifespan.

Tips for implementing shot peening effectively include selecting the appropriate media size and type based on the material and geometry of the component. Additionally, it is essential to determine the optimal intensity and duration of the peening process to achieve the desired surface profile. Regularly inspecting components after peening can also ensure that they meet the stringent specifications required for their intended application, preventing unexpected failures during operation.

Integrating shot peening into regular maintenance schedules can provide long-term cost savings and reliability. Industries such as aerospace, automotive, and manufacturing can greatly benefit from this technique, as it not only enhances component longevity but also ensures that equipment performs at its best, reducing downtime and increasing overall productivity.

Case Studies: Real-World Applications of Shot Peening in Aerospace and Automotive Industries

Shot peening has gained significant traction in the aerospace and automotive industries, where the longevity of components is paramount. In aerospace applications, components such as turbine blades and structural parts often face extreme conditions. Case studies reveal that shot peening these components can effectively enhance fatigue resistance, allowing them to endure stresses that would typically lead to failure after a comparatively short operational life. For instance, a major aircraft manufacturer implemented shot peening on their titanium landing gear components, resulting in a longevity increase of up to 50 percent, which not only improved reliability but also reduced maintenance costs.

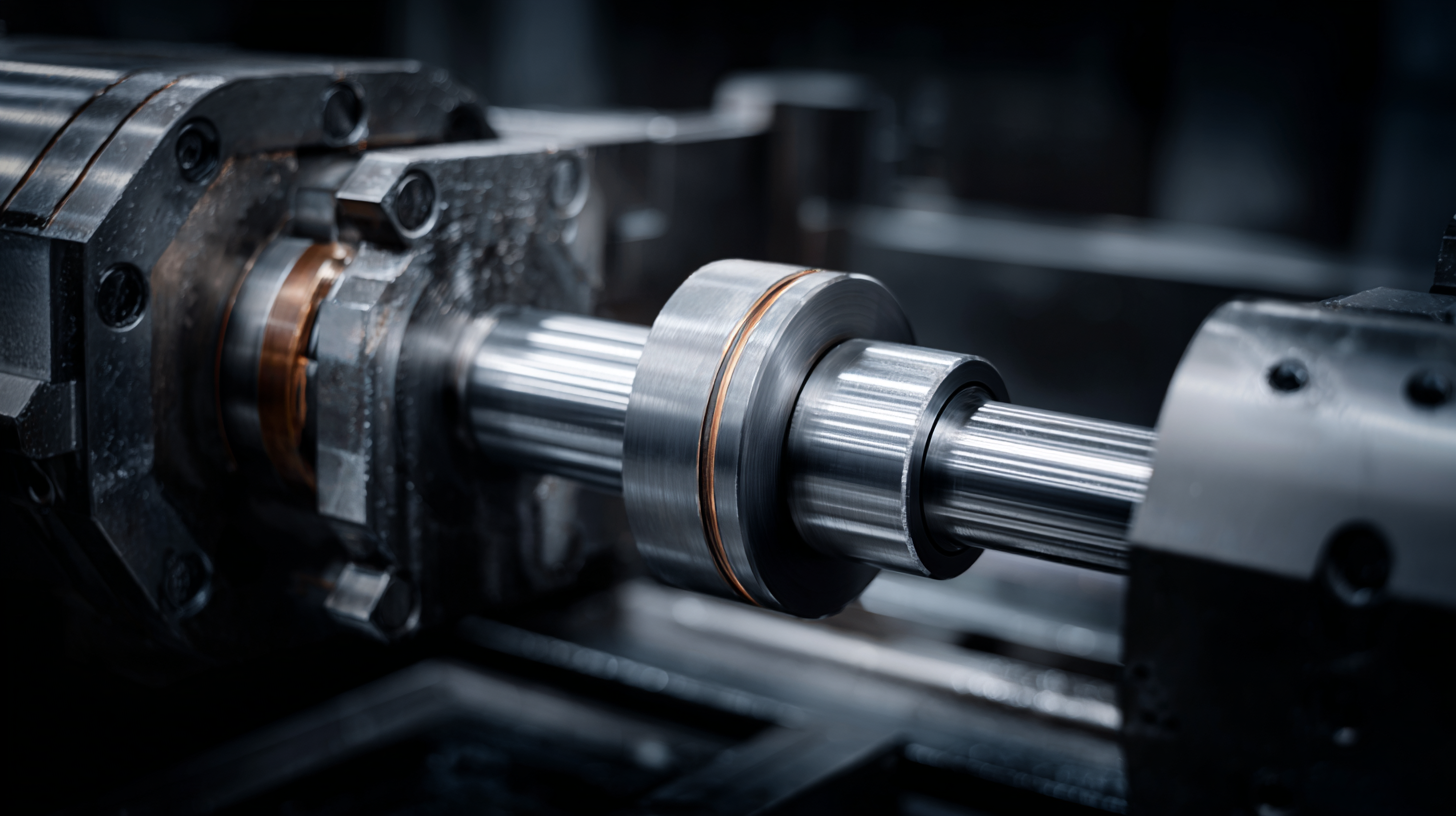

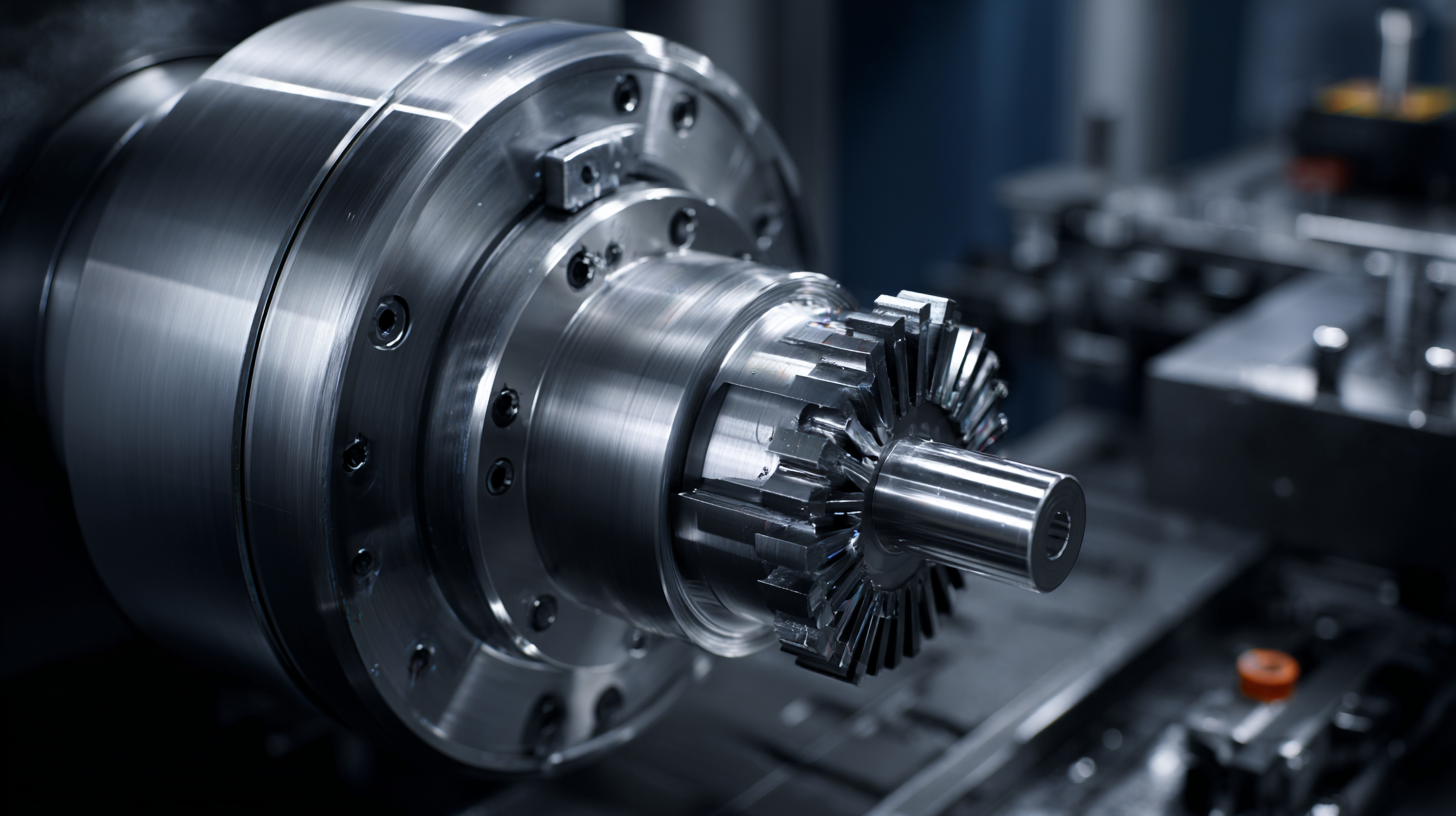

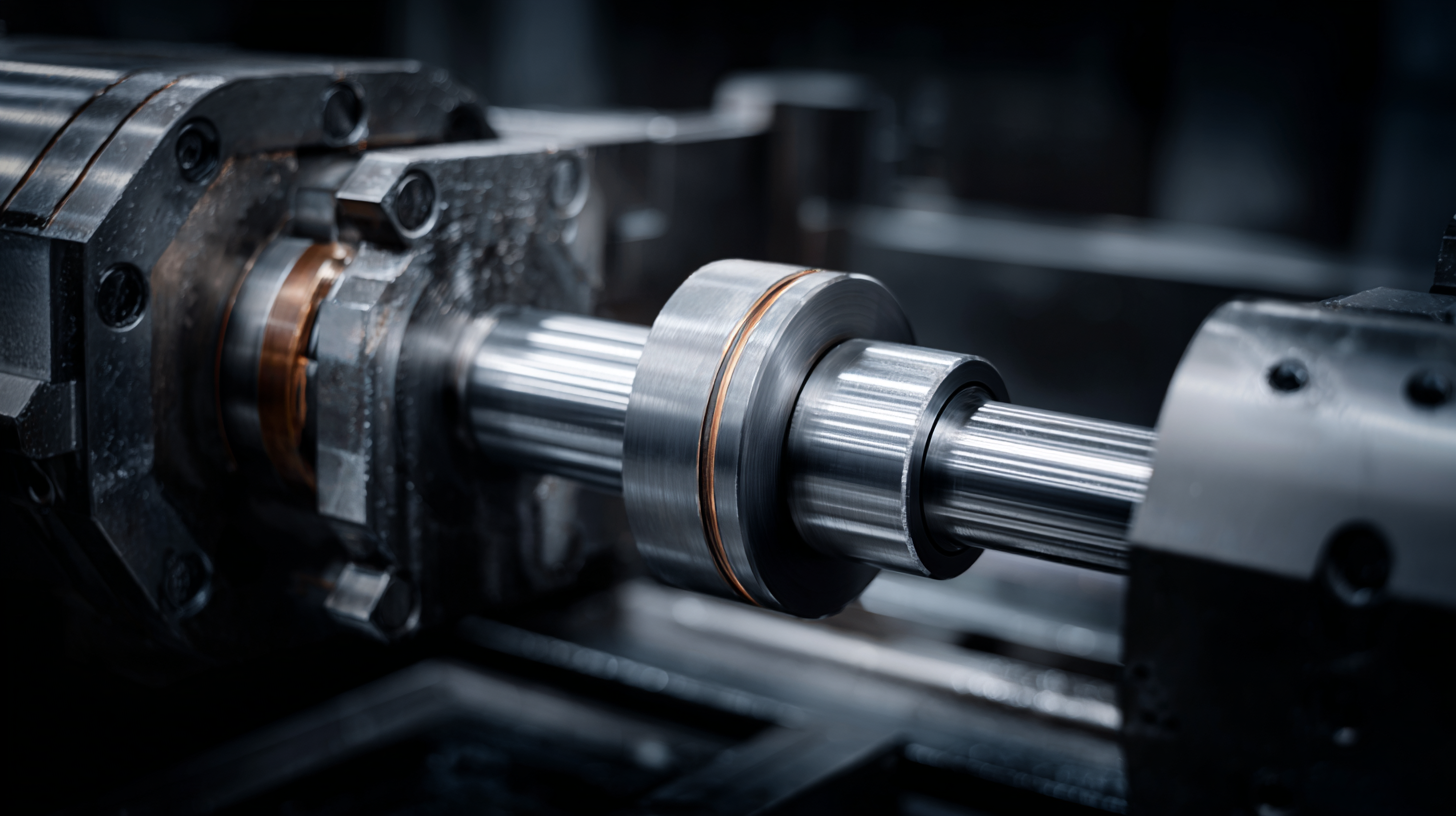

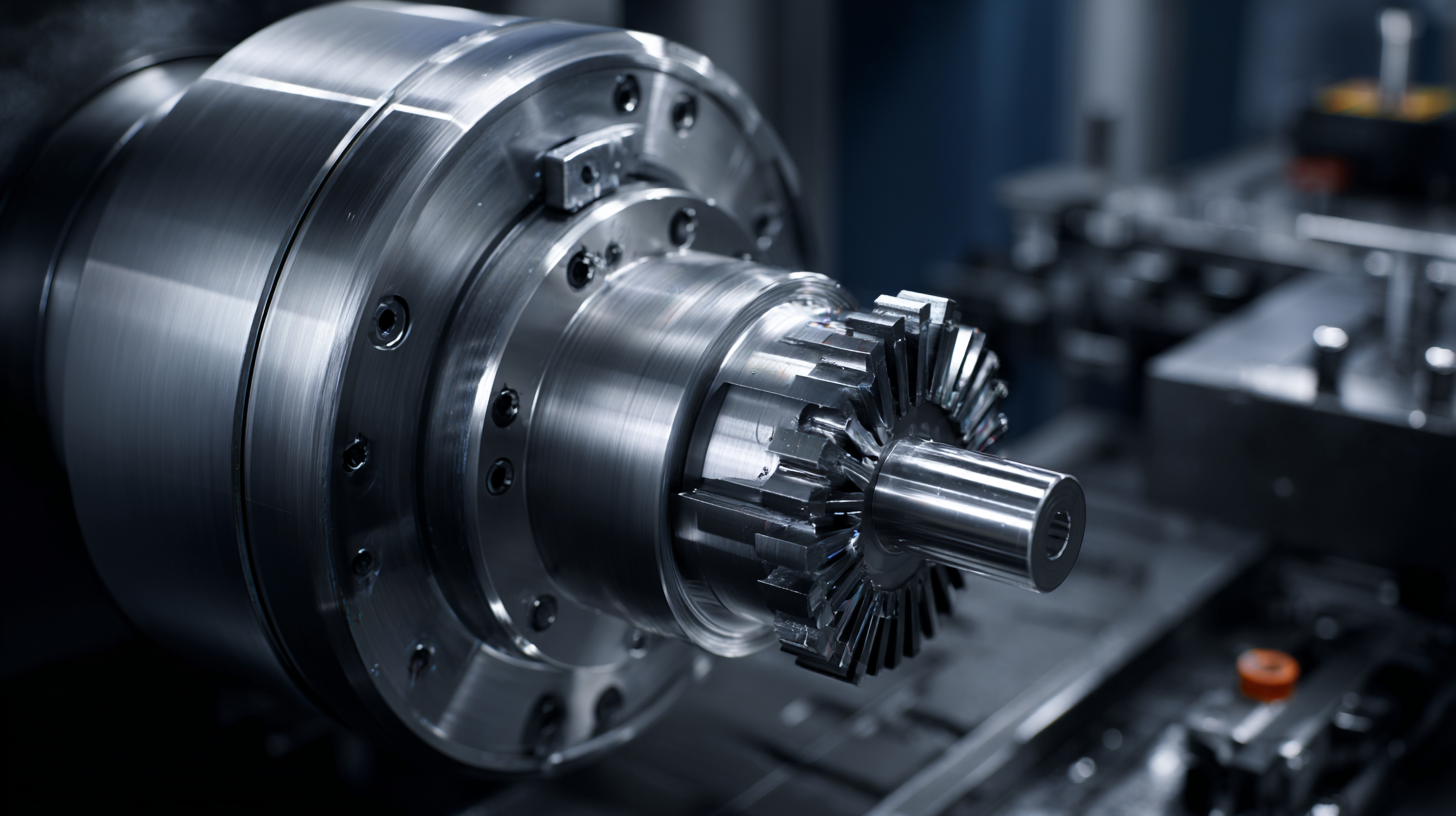

Similarly, in the automotive sector, shot peening is frequently utilized to strengthen critical parts such as crankshafts and gears. By inducing compressive residual stresses on the surface of these components, manufacturers have documented a significant decrease in wear rates and overall failure occurrences. A notable example involved a leading automotive manufacturer that adopted shot peening on their high-performance engine components, which led to a dramatic reduction in warranty claims related to engine malfunctions. This real-world application underscores the transformative impact of shot peening technology on both performance and durability in high-stakes industries.

Future Trends: Innovations in Shot Peening Technology for Enhanced Longevity

Recent advancements in shot peening technology are transforming the landscape of component longevity in various industries. Innovations such as automated shot peening processes and sophisticated control systems are enabling manufacturers to achieve more consistent and effective treatments. The integration of smart technology, including real-time monitoring and data analytics, allows for precise adjustments during the peening process, ensuring optimal performance and minimizing material fatigue. This level of control enhances the efficiency of shot peening, making it possible to extend the lifespan of components significantly.

Furthermore, the development of new peening materials and techniques is driving enhanced outcomes. For instance, researchers are experimenting with novel media that provide superior surface finish and increased residual compressive stress, ultimately leading to improved fatigue resistance. Additionally, eco-friendly shot peening solutions are gaining traction, reflecting a commitment to sustainability in manufacturing practices. As these innovations continue to evolve, they promise not only to bolster the durability of components but also to reduce maintenance costs and improve overall product reliability across numerous applications.

Impact of Shot Peening on Component Longevity

This chart illustrates the enhancement in component longevity due to various shot peening processes compared to untreated components. The data shows significant improvements with different peening intensities.

Home

Equipment

Vacuum Process Casting Molding Line

Automatic Flaskless Sand Molding Production Line

Sand Preparation Automation Line

Shot Blasting Peening Equipment

Stainless Steel Stripe Shot Blasting Machine

Steel Preservation Line

Roller Conveyor Shot Blasting Machine

Hook Type Shot Blasting Machine

Pass Through Monorail Shot Blasting Machine

Mesh Belt Shot Blasting Machine

Rotary Table Shot Blasting Machine

Trolley Type Shot Blasting Machine

Steel Pipe Shot Blasting Machine

Crawler Type Shot Blasting Machine

Rolling Drum Shot Blasting Machine

Automatic Titling Drum Shot Blasting Machine

Portable Shot Blasting Machine

Abrasive Blast Booth And Spray Paint Booth

Enviromental Dust Removal Equipment

Why Xinke

News Room

Blog

Contact Us