Revolutionizing Surface Preparation: The Role of Steel Pipe Blasting Machines in Industry Efficiency

In the ever-evolving landscape of industrial manufacturing, the efficiency of surface preparation processes plays a pivotal role in determining the overall productivity and longevity of finished products. A significant advancement in this arena is the Steel Pipe Blasting Machine, an equipment that has transformed how industries prepare surfaces for coating, welding, or other treatments. According to a recent report by the International Association of Cleaning and Surface Preparation (IACSP), companies utilizing automated blasting technologies can achieve up to a 30% increase in efficiency while simultaneously reducing waste material by 25%. This notable enhancement not only streamlines operations but also promotes sustainability—a growing concern for manufacturers worldwide. As industries strive to optimize performance and meet stringent quality standards, the incorporation of Steel Pipe Blasting Machines stands out as a crucial strategy to revolutionize surface preparation and drive sector-wide benefits.

Understanding Steel Pipe Blasting Machines and Their Mechanisms in Surface Preparation

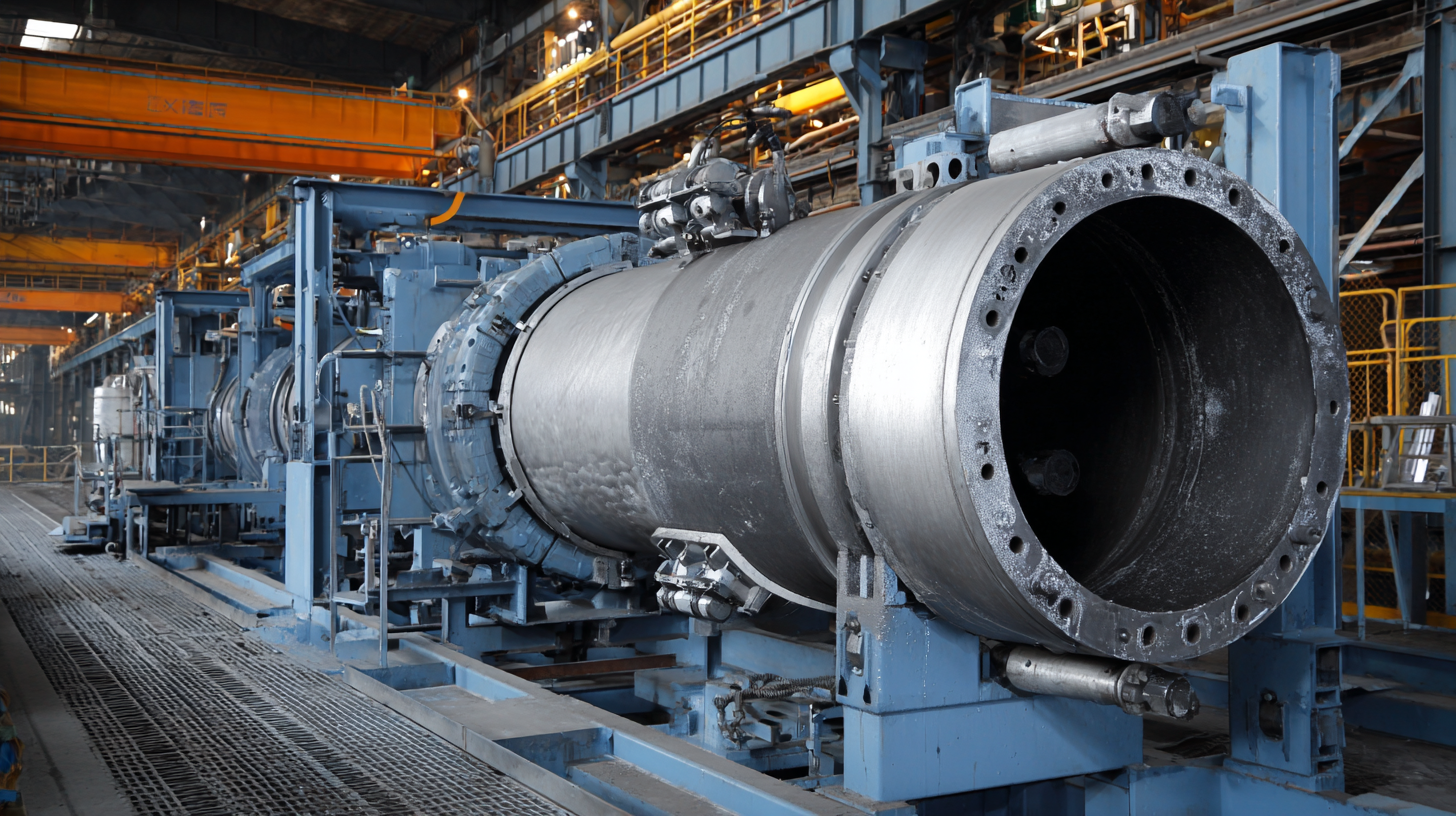

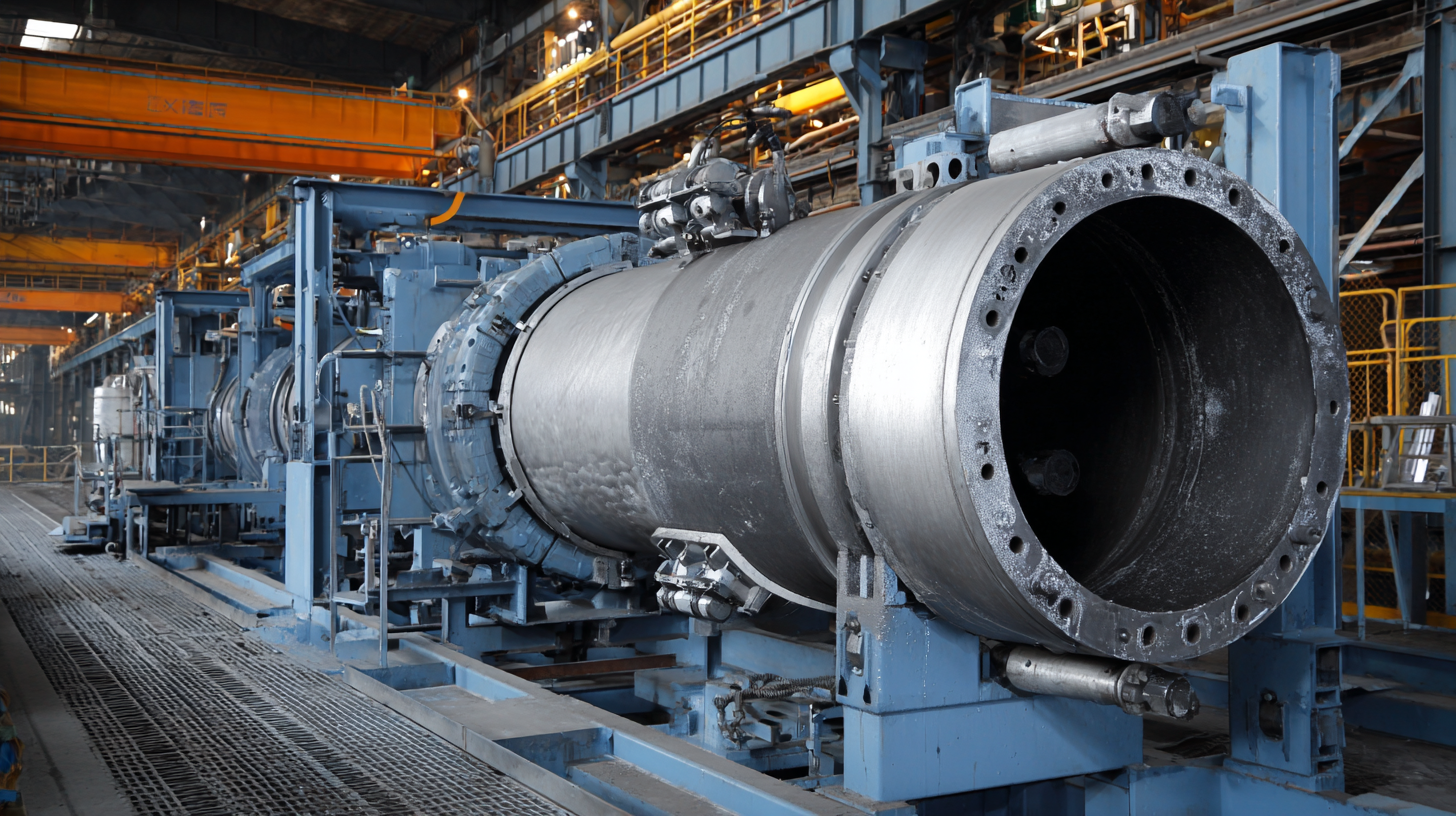

Steel pipe blasting machines have emerged as a crucial element in modern surface preparation, fundamentally enhancing the efficiency and quality of industrial processes. These machines utilize high-velocity abrasive materials to remove contaminants, rust, and old coatings from steel surfaces, preparing them for subsequent treatments or applications. According to a report from the Global Abrasive Blasting Equipment Market, the demand for such equipment is projected to grow at a CAGR of 6.5% through 2027, highlighting the increasing recognition of their importance within various industries, including oil and gas, construction, and manufacturing.

The mechanisms behind steel pipe blasting machines involve a combination of mechanical and pneumatic technologies that ensure a consistent and thorough surface finish. Equipped with advanced features such as automated controls and adjustable pressure settings, these systems can significantly reduce material waste and labor costs. A study published by the American Society for Testing and Materials indicates that proper surface preparation can increase the lifespan of protective coatings by up to 50%. This proves that investing in efficient blasting technologies not only optimizes operational workflows but also enhances the durability of coated products in harsh environments.

Key Benefits of Steel Pipe Blasting Machines for Enhanced Industrial Efficiency

The utilization of steel pipe blasting machines has greatly transformed the landscape of industrial surface preparation, offering significant benefits that enhance overall efficiency. One of the primary advantages is the ability to achieve superior surface cleaning and preparation. These machines utilize high-velocity abrasive materials to effectively remove contaminants, rust, and old coatings from surfaces, ensuring that the new finishes adhere properly. This results in longer-lasting coatings and reduced maintenance costs, thereby maximizing productivity.

Additionally, steel pipe blasting machines streamline the surface preparation process. Their automated systems allow for consistent and rapid operations, reducing manual labor and the time associated with surface treatments. This efficiency enables industries to accelerate production timelines and respond quickly to market demands. By minimizing downtime and labor costs while maximizing surface quality, these machines play a crucial role in enhancing operational efficiency across various sectors, including construction, manufacturing, and oil and gas. Overall, the implementation of steel pipe blasting technology represents a significant step towards optimizing industrial processes.

Key Benefits of Steel Pipe Blasting Machines for Enhanced Industrial Efficiency

This chart illustrates the key benefits of using steel pipe blasting machines in industrial applications, highlighting improvements in efficiency, cost savings, and surface quality.

Statistical Analysis of Time and Cost Savings Achieved with Blasting Technology

The integration of steel pipe blasting machines into industrial processes has dramatically enhanced time and cost efficiency. A recent statistical analysis revealed that companies utilizing blasting technology have reported up to a 40% reduction in surface preparation time compared to traditional methods. As equipment and labor costs can consume up to 60% of a project's budget, these advancements are not just beneficial but essential for competitiveness in the modern market.

Tips for maximizing the benefits of steel pipe blasting machines include regular maintenance and operator training. Ensuring your machinery receives timely upkeep can extend its lifespan and enhance its performance, ultimately leading to further savings. Additionally, investing in comprehensive training programs for staff can increase operational efficiency—operators familiar with the capabilities of the blasting machines can optimize their usage, reducing waste and downtime.

Furthermore, data from the Industrial Blasting Association indicates that companies employing blasting technology save an average of 25% on operational costs per project. This level of efficiency allows businesses to allocate resources to other critical areas, paving the way for innovation and growth while maintaining high standards in surface preparation and finishing.

Revolutionizing Surface Preparation: The Role of Steel Pipe Blasting Machines in Industry Efficiency

| Industry Sector |

Time Savings (Hours per Project) |

Cost Savings ($ per Project) |

Efficiency Improvement (%) |

| Oil & Gas |

120 |

5000 |

15 |

| Construction |

95 |

4200 |

12 |

| Manufacturing |

80 |

3000 |

10 |

| Automotive |

100 |

4500 |

14 |

| Shipbuilding |

110 |

5200 |

16 |

Comparative Study: Traditional Surface Preparation vs. Steel Pipe Blasting Approaches

In the realm of surface preparation, traditional methods often rely heavily on manual labor and straightforward techniques, such as hand sanding or chemical stripping. These approaches can be labor-intensive and time-consuming, potentially leading to inconsistent results. For industries that prioritize precision and efficiency, such drawbacks can hinder productivity and elevate costs. Furthermore, traditional methods may expose workers to hazardous materials, posing health risks that could be mitigated through modern alternatives.

Conversely, steel pipe blasting machines offer a revolutionary solution that optimizes surface preparation processes. These machines utilize abrasive blasting technology that effectively removes impurities, rust, and old coatings, preparing the surface for subsequent applications. The uniformity and efficiency of this method significantly reduce preparation time, allowing for faster project turnaround while ensuring high-quality results. By automating the blasting process, industries can minimize the exposure of workers to hazardous substances and reduce labor costs, ultimately enhancing overall operational efficiency. This comparative study underscores a critical shift towards more modern, effective techniques that align with the evolving demands of industrial standards.

Future Trends in Steel Pipe Blasting Technology and Industry Impact Predictions

The steel industry is poised for significant transformation as we look ahead to the 2025-2035 period, particularly with the advent of advanced technologies in steel pipe blasting. The global iron and steel market, valued at USD 1,453.4 billion in 2024, is expected to reach USD 1,707.1 billion by 2030, driven by increasing demand for efficient production methods. The integration of low-carbon technologies such as hydrogen direct reduction ironmaking (hydrogen-DRI) and electrochemical ironmaking is vital for achieving sustainability goals while enhancing operational efficiency.

India stands as a formidable player in this revolution, projecting a domestic steel demand growth of 9-10% with production reaching 51.46 million tons in FY26. However, the industry also faces challenges, notably a shortfall in scrap supply that could impede growth. As the industry strives to align with Net Zero Emissions by 2050, innovations in blasting technology and processing methods are critical for maintaining competitiveness and meeting regulatory standards. Such advancements not only promise to increase efficiency but also support the broader climate commitments outlined in the Paris Agreement.

Home

Equipment

Vacuum Process Casting Molding Line

Automatic Flaskless Sand Molding Production Line

Sand Preparation Automation Line

Shot Blasting Peening Equipment

Stainless Steel Stripe Shot Blasting Machine

Steel Preservation Line

Roller Conveyor Shot Blasting Machine

Hook Type Shot Blasting Machine

Pass Through Monorail Shot Blasting Machine

Mesh Belt Shot Blasting Machine

Rotary Table Shot Blasting Machine

Trolley Type Shot Blasting Machine

Steel Pipe Shot Blasting Machine

Crawler Type Shot Blasting Machine

Rolling Drum Shot Blasting Machine

Automatic Titling Drum Shot Blasting Machine

Portable Shot Blasting Machine

Abrasive Blast Booth And Spray Paint Booth

Enviromental Dust Removal Equipment

Why Xinke

News Room

Blog

Contact Us