Effective Tips for Using a Spinner Hanger Shot Blasting Machine Efficiently

The Spinner Hanger Shot Blasting Machine is a vital tool in various industries, particularly for surface preparation and cleaning processes. Its design allows for efficient blasting of components that are hung or suspended, ensuring comprehensive coverage and effective removal of contaminants. As industrial demands grow, optimizing the use of the Spinner Hanger Shot Blasting Machine becomes essential for enhancing productivity and maintaining quality standards.

In this article, we will explore effective tips for utilizing the Spinner Hanger Shot Blasting Machine more efficiently. From understanding the operational parameters to implementing best practices for the setup and maintenance, each aspect plays a crucial role in maximizing the machine's capabilities. By integrating these tips, operators can not only improve their workflow but also minimize downtime and extend the lifespan of the equipment, ultimately leading to cost savings and improved output.

As we delve into these strategies, we aim to equip users with the knowledge necessary to leverage the full potential of the Spinner Hanger Shot Blasting Machine, thereby elevating their operational efficiency and ensuring superior surface finishing results.

Understanding the Basics of Spinner Hanger Shot Blasting Machines

Spinner hanger shot blasting machines

are essential tools in various industries for surface preparation and cleaning. These machines utilize a rotating hanger that holds workpieces in place while high-velocity steel shot is propelled towards the surface.

The process effectively removes contaminants such as rust, paint, and scale, while also providing a uniform finish. Understanding the mechanics behind these machines is crucial for achieving optimal results.

One key aspect of spinner hanger shot blasting machines is their ability to accommodate different sizes and shapes of workpieces. The adjustable fixtures on the hangers allow for a secure grip, ensuring that items remain stable during the blasting process. Additionally, the orientation of the hanger can be manipulated to target specific areas of the workpiece, enhancing the efficiency of the blasting operation. Proper maintenance of the machine and the shot media is also vital, as this ensures consistent performance and prolongs the equipment's lifespan, ultimately leading to cost savings and improved productivity.

Key Components and Features of Spinner Hanger Shot Blasting Machines

Spinner hanger shot blasting machines are engineered with several key components that play a crucial role in their efficiency and effectiveness. At the heart of these machines is the spinner hanger itself, which is designed to hold and rotate workpieces securely during the blasting process. This ensures comprehensive coverage and uniform treatment of surfaces, allowing for optimal clean-up and preparation. Additionally, the design of the spinner hanger allows for easy loading and unloading of parts, thereby significantly reducing downtime between operations.

Another vital feature of these machines is the high-velocity blast wheels, which propel abrasive materials at high speeds to achieve desired surface finishes. The blast wheels can often be adjusted to change the intensity and direction of the blasting, offering flexibility for different materials and cleaning requirements. Furthermore, an advanced dust collection system is often integrated into the machine to maintain a clean working environment by capturing spent abrasives and contaminants. This not only enhances operator safety but also minimizes environmental impact, showcasing the machine’s design for efficiency and user consideration.

Effective Tips for Using a Spinner Hanger Shot Blasting Machine Efficiently - Key Components and Features

| Component/Feature |

Description |

Importance |

| Blast Wheel |

Generates the centrifugal force to propel abrasive media. |

Critical for achieving efficiency and uniform surface coverage. |

| Hanger System |

Supports the items being blasted, allowing for better movement and coverage. |

Ensures even exposure of all surfaces to the abrasive media. |

| Abrasive Media |

Material used for surface preparation, available in various types and sizes. |

Choosing the right media ensures optimal cleaning and finishing results. |

| Dust Collection System |

Removes dust and debris from the environment to maintain clean working conditions. |

Improves visibility and worker safety during operation. |

| Control System |

Manages the operation settings, including timing and intensity of blasting. |

Allows for customization of the blasting process for different tasks. |

Best Practices for Loading and Operating Shot Blasting Machines

When operating a spinner hanger shot blasting machine, proper loading and operational techniques are crucial for maximizing efficiency and ensuring consistent results. Industry studies indicate that up to 30% of production time can be lost due to improper loading practices. Therefore, understanding how to load components effectively is essential. Ensure that the parts are securely hung on the spinner hangers to avoid movement during the blasting process, as even slight shifting can lead to uneven surface treatment and wasted materials.

Tips for efficient loading include balancing the weight of the components on the hangers, which not only improves blasting efficiency but also prolongs the life of the machine. Additionally, aligning the center of gravity with the axis of the spinner can enhance the overall stability throughout the blasting cycle. The optimal arrangement should allow for maximum exposure to the abrasive media while minimizing blast shadowing between the components.

When it comes to operation, maintaining the correct abrasive media flow rate is a key factor in achieving desired surface finishes. Research suggests that using a consistent flow rate, adjusted according to the specific type of material being treated, can improve productivity by up to 25%. Regularly checking and calibrating the machine’s components, such as the motor and control settings, can also prevent unforeseen downtimes. Prioritizing these best practices in loading and operation will lead to improved outcomes and greater longevity of your shot blasting machine.

Common Maintenance Tips for Enhancing Machine Efficiency

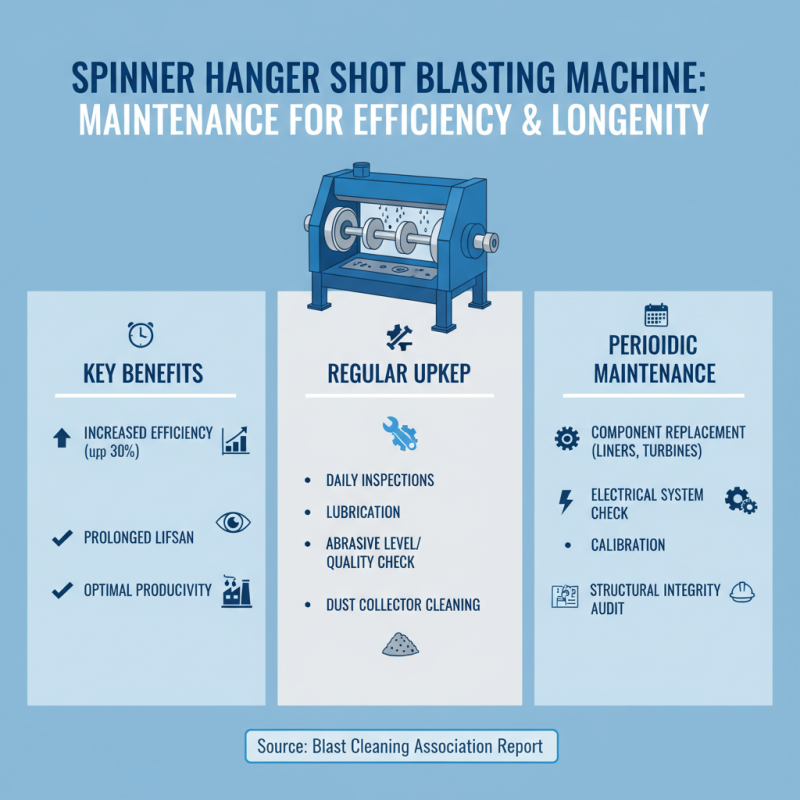

Maintaining a spinner hanger shot blasting machine is crucial for maximizing its efficiency and prolonging its lifespan. Regular upkeep not only enhances performance but also ensures optimal productivity in operational environments. According to a report by the Blast Cleaning Association, proper maintenance can increase machine efficiency by up to 30%, making it a worthwhile investment for manufacturers.

One essential maintenance tip is to routinely inspect and clean the blasting wheels. Accumulated debris and wear can significantly diminish their effectiveness. It is recommended to check the wheels weekly; replacing worn parts can lead to a noticeable improvement in blasting performance and ensure consistent surface preparation. Additionally, maintaining proper alignment and tension of the conveyor chain is vital to prevent excess strain on the machine components.

Another critical aspect is monitoring the quality of the abrasive media. Using the right type and clean abrasives not only enhances efficiency but also minimizes wear and tear on the machine. Regularly screening and replacing the abrasive can lead to cleaner surfaces and improved operational speeds. According to industry studies, maintaining high-quality abrasives can reduce rework rates by as much as 25%. By adhering to these maintenance tips, operators can optimize their spinner hanger shot blasting machines for better performance and reliability.

Safety Precautions When Using Spinner Hanger Shot Blasting Machines

When operating a spinner hanger shot blasting machine, safety precautions are paramount to ensure not only the well-being of the operators but also the integrity of the equipment and the quality of the work performed. One of the fundamental steps is to ensure that all personnel wear appropriate personal protective equipment (PPE). This includes safety goggles, gloves, and respiratory protection, as these machines can create flying debris and dust that poses significant health risks if inhaled or if it contacts the skin.

Additionally, it is crucial to conduct regular maintenance checks on the machine before every use. Inspecting components such as the blast wheel, enclosure, and safety guards can prevent malfunctions that might lead to accidents. Operators should be trained in the correct operating procedures, emphasizing the importance of not bypassing safety features or guards. Proper training not only reduces the likelihood of accidents but also fosters a safety-first culture among workers. Maintaining a clean and organized workspace is equally important, as clutter can lead to slips and falls, further ensuring a safe working environment.

Efficiency Metrics for Spinner Hanger Shot Blasting Machines

Home

Equipment

Vacuum Process Casting Molding Line

Automatic Flaskless Sand Molding Production Line

Sand Preparation Automation Line

Shot Blasting Peening Equipment

Stainless Steel Stripe Shot Blasting Machine

Steel Preservation Line

Roller Conveyor Shot Blasting Machine

Hook Type Shot Blasting Machine

Pass Through Monorail Shot Blasting Machine

Mesh Belt Shot Blasting Machine

Rotary Table Shot Blasting Machine

Trolley Type Shot Blasting Machine

Steel Pipe Shot Blasting Machine

Crawler Type Shot Blasting Machine

Rolling Drum Shot Blasting Machine

Automatic Titling Drum Shot Blasting Machine

Portable Shot Blasting Machine

Abrasive Blast Booth And Spray Paint Booth

Enviromental Dust Removal Equipment

Why Xinke

News Room

Blog

Contact Us