Top 5 Automated Blasting Machines for Efficient Industrial Cleaning Solutions

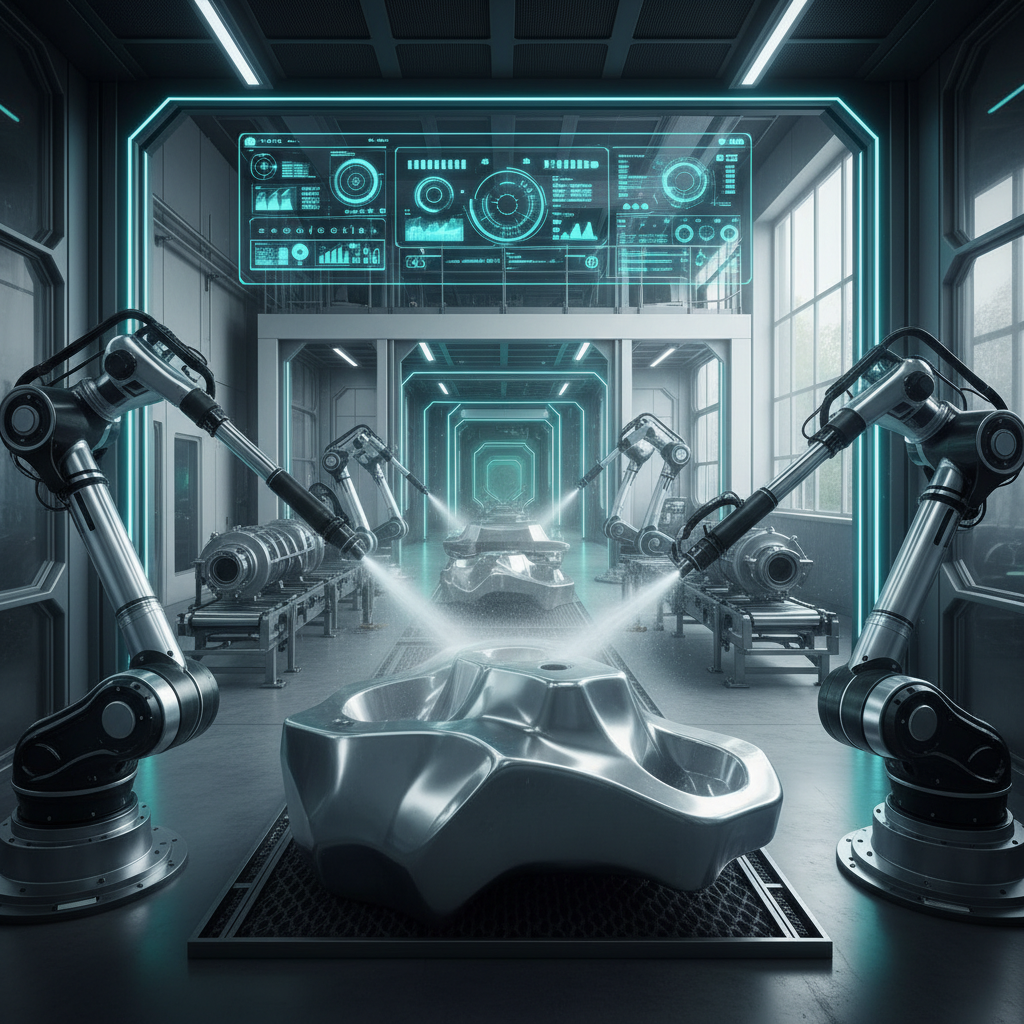

In the realm of industrial cleaning, the advent of

Automated Blasting Machines

has revolutionized operational efficiency and effectiveness. With industries increasingly focusing on

sustainability and

productivity, these innovative machines offer a compelling solution to meet the rigorous demands of modern manufacturing.

According to a recent report by MarketsandMarkets, the global automated blasting equipment market is projected to grow from

USD 1.5 billion in 2020 to

USD 2.3 billion by 2025, underscoring the rising adoption of automation in industrial processes.

Experts in the field, such as Dr. Michael Stone, an authority on industrial automation, emphasize the transformative impact of these machines.

He notes, “Automated Blasting Machines not only enhance cleaning precision but also significantly reduce labor costs and environmental impact,

making them indispensable in today’s manufacturing landscape.” As businesses strive for operational excellence, investing in automated technology is no longer just an option but a necessity for staying competitive.

This article explores the

top five Automated Blasting Machines available in the market,

focusing on their unique features, efficiencies, and the pivotal role they play in streamlining industrial cleaning processes.

By examining these leading solutions, we aim to provide valuable insights for organizations looking to improve their cleaning operations in

2025 and beyond.

Emerging Trends in Automated Blasting Technology for 2025

As we look towards 2025, the trends in automated blasting technology are set to reshape the landscape of industrial cleaning solutions. With an increasing emphasis on efficiency and productivity, companies are investing in advanced automated blasting systems that not only enhance cleaning performance but also reduce operational costs. According to a recent industry report by MarketsandMarkets, the global automated blasting equipment market is projected to grow from $4.2 billion in 2022 to $6.3 billion by 2025, driven by rising demand for eco-friendly surface preparation methods and the growing adoption of automation across various sectors.

One of the emerging trends is the integration of smart technologies, such as IoT and machine learning, which allow for real-time monitoring and data analysis. This not only increases efficiency but also enhances safety by minimizing human exposure to hazardous materials. Additionally, advancements in nozzle design and blasting media are leading to improved cleaning results with less waste.

**Tip:** When selecting an automated blasting machine, consider models that incorporate smart capabilities to optimize operations and improve maintenance schedules.

Another significant trend is the focus on sustainability. Automated blasting machines are now being designed to use recycled materials and minimize waste generation. Companies are increasingly prioritizing equipment that complies with environmental regulations while maintaining high performance standards.

**Tip:** Evaluate the sustainability features of any automated blasting system, as investing in greener technologies can enhance your company's brand reputation and compliance with regulations.

Key Features to Look for in Top Automated Blasting Machines

When considering automated blasting machines for industrial cleaning, it's essential to focus on key features that maximize efficiency and effectiveness. One crucial aspect is the machine's capability to adjust the abrasive material size and type. Machines that provide versatility in abrasive options can tackle various surfaces and contaminants, ensuring a thorough clean without damaging the underlying material. Another important feature is the machine's automation level; advanced machines often come with programmable settings that enhance precision and reduce operator intervention, resulting in consistent cleaning results.

Tips for choosing the right automated blasting machine include assessing the size and layout of your workspace. Compact models may work better in confined areas, while larger machines can cover extensive surfaces more quickly. Additionally, consider the machine's maintenance requirements. Models designed for easy cleaning and part replacement will save time and reduce downtime in the long run. Lastly, evaluate the support and training offered by manufacturers, as proper operation and upkeep are vital for maximizing the machine's lifespan and efficiency.

Top 5 Automated Blasting Machines - Efficiency Comparison

This bar chart illustrates the efficiency ratings of the top 5 automated blasting machines based on their cleaning speed (in square meters per hour) and material usage (in kilograms per hour). The data reflects the performance characteristics that industries should consider when selecting an automated blasting machine.

Comparative Analysis of the Top 5 Automated Blasting Solutions

The increasing demand for efficiency in industrial cleaning has led to the rise of automated blasting machines, which are revolutionizing how tasks are performed across various industries. A comparative analysis of the top automated blasting solutions reveals significant advancements in technology that enhance effectiveness and safety. For instance, recent data from industry reports indicates that automated blasting can increase productivity by up to 30%, while simultaneously reducing labor costs by as much as 25%. These machines utilize precision controls to optimize blasting parameters, leading to better surface finishes and reduced material waste.

In addition, new technologies being implemented, such as advanced monitoring systems, ensure that blasting operations adhere to the highest safety standards. As highlighted in expert insights on blasting safety, updated protocols are crucial in mining operations where automated systems are being increasingly integrated. Automating blasting processes not only minimizes the exposure of personnel to hazardous environments but also enhances overall operational safety by utilizing real-time data to manage risks effectively. The combination of efficiency, safety, and sustainability makes these automated solutions an essential investment for industries looking to modernize their cleaning operations.

Industry Applications: How Automated Blasting Enhances Cleaning Efficiency

Automated blasting machines are revolutionizing the industrial cleaning landscape, enabling companies to enhance their cleaning efficiency across various applications. With industries increasingly focusing on productivity and cost-effectiveness, automated blasting technology provides a solution that not only saves time but also ensures consistent cleaning results. By automating the cleaning process, these machines reduce the need for manual labor while improving safety and precision in operations. This is particularly beneficial in sectors such as manufacturing and oil and gas, where stringent cleanliness standards are required.

The versatility of automated blasting machines allows them to be tailored for specific industrial applications, making them suitable for diverse environments. Their ability to perform in challenging conditions enhances operational efficiency, whether for surface preparation, derusting, or residue removal. Moreover, advancements in technology have led to the development of machines that utilize different blasting techniques, ensuring optimal performance. As industries evolve, the integration of automated blasting solutions will likely continue to grow, driving innovation in cleaning practices and setting new standards for efficiency across the board.

Cost-Benefit Evaluation of Investing in Automated Blasting Machines

Investing in automated blasting machines can significantly enhance industrial cleaning processes while optimizing costs. The shot blasting machine market is forecasted to grow from $1.41 billion in 2025 to $2.22 billion by 2032, reflecting a compound annual growth rate (CAGR) of 6.7%. This growth underscores the increasing demand for efficient cleaning solutions across various industries. Moreover, the dry sand blasting segment leads the market, comprising 74.4% of the total due to its cost-effectiveness and adaptability in diverse industrial applications.

Tips: When considering an automated blasting machine, evaluate not only the initial investment but also the long-term maintenance and operational costs. Opting for machines that require less frequent maintenance can lead to higher efficiency and cost savings over time. Additionally, assess the versatility of the machine—those that can handle various materials will offer better value as they cater to different cleaning needs without the requirement for multiple machines.

Another aspect to consider is the technological advancements in this field, which contribute to better performance and efficiency. Machines equipped with innovative features often result in quicker job completion times, allowing for increased productivity and reduced downtime in operations.

Top 5 Automated Blasting Machines for Efficient Industrial Cleaning Solutions

| Machine Model |

Cleaning Efficiency (sq.ft/hour) |

Operating Cost (per hour) |

Initial Investment ($) |

Return on Investment (Years) |

| Model A |

500 |

$30 |

$25,000 |

2.5 |

| Model B |

450 |

$25 |

$20,000 |

2.2 |

| Model C |

600 |

$35 |

$30,000 |

2.8 |

| Model D |

550 |

$32 |

$27,000 |

2.6 |

| Model E |

400 |

$20 |

$15,000 |

2.0 |

Home

Equipment

Vacuum Process Casting Molding Line

Automatic Flaskless Sand Molding Production Line

Sand Preparation Automation Line

Shot Blasting Peening Equipment

Stainless Steel Stripe Shot Blasting Machine

Steel Preservation Line

Roller Conveyor Shot Blasting Machine

Hook Type Shot Blasting Machine

Pass Through Monorail Shot Blasting Machine

Mesh Belt Shot Blasting Machine

Rotary Table Shot Blasting Machine

Trolley Type Shot Blasting Machine

Steel Pipe Shot Blasting Machine

Crawler Type Shot Blasting Machine

Rolling Drum Shot Blasting Machine

Automatic Titling Drum Shot Blasting Machine

Portable Shot Blasting Machine

Abrasive Blast Booth And Spray Paint Booth

Enviromental Dust Removal Equipment

Why Xinke

News Room

Blog

Contact Us