Top Steel Pipe Blasting Machine Types for Efficient Surface Preparation?

In the world of industrial cleaning and surface preparation, the importance of effective machinery cannot be overstated. As John Smith, an expert in the Steel Pipe Blasting Machine industry, once said, “Choosing the right blasting machine can significantly affect the efficiency of surface preparation.” This statement highlights the crucial role that these machines play in ensuring high-quality finish and durability of steel pipes.

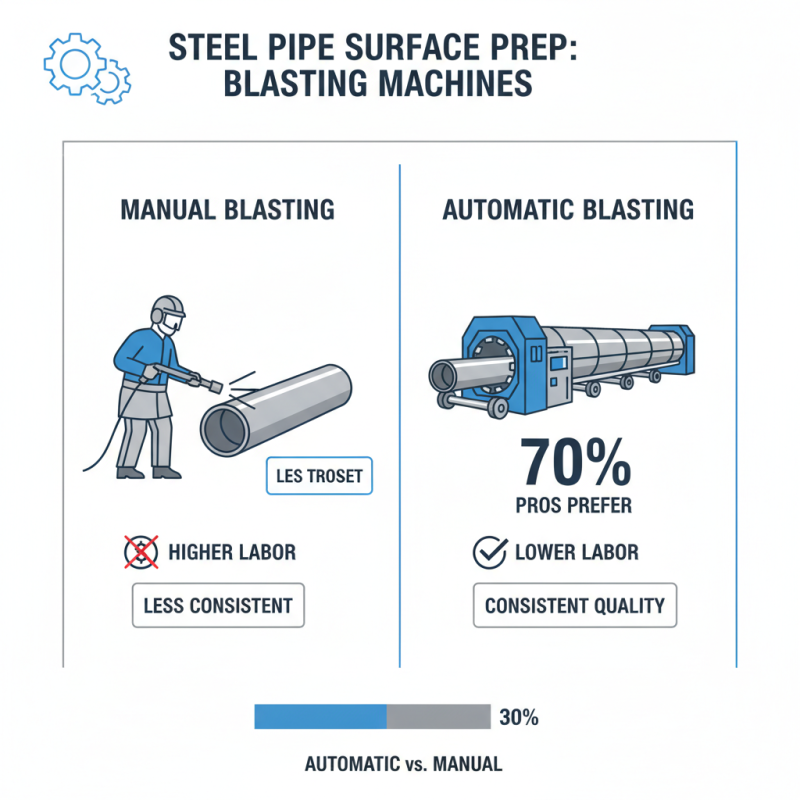

Steel Pipe Blasting Machines come in various types, each designed for specific applications. From automated systems to portable units, the differences can be striking. For instance, automated machines often provide consistent results and reduce labor costs, while portable units offer flexibility for on-site projects. However, not every machine suits every task, and knowing which method to employ can be challenging.

Despite advancements, issues persist within the industry. Some machines may struggle with specific coatings or materials, leading to inadequate surface preparation. Furthermore, the initial cost for high-quality blasting machines can deter some companies. Reflecting on these challenges can lead to a deeper understanding of the importance of innovation and adaptation within the Steel Pipe Blasting Machine field.

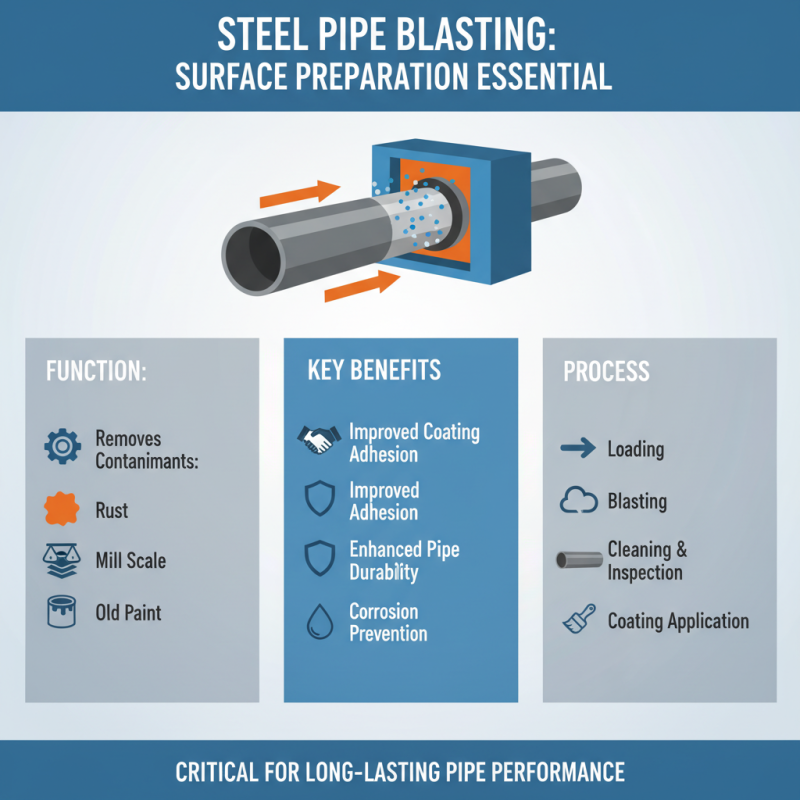

Overview of Steel Pipe Blasting Machines and Their Importance

Steel pipe blasting machines play a critical role in surface preparation. They are essential for cleaning and preparing steel pipes for various uses. These machines remove contaminants such as rust, scale, and old paint. A clean surface helps improve the adhesion of coatings. It also enhances the durability of the pipes.

Modern blasting machines come in various types. Each type has unique features and efficiency levels. Abrasive blasting is common for heavy-duty applications. Automated systems offer high efficiency, but manual machines can be easier to control. Both types have pros and cons that should be considered based on specific requirements.

Tips: Regular maintenance of blasting machines is crucial. Check for wear and tear. Clean the components frequently to maintain performance. Additionally, always ensure proper safety gear is worn when operating these machines. Safety cannot be overlooked, as it protects operators and ensures a safe working environment.

Types of Steel Pipe Blasting Machines for Different Applications

When it comes to steel pipe blasting machines, several types cater to unique applications. These machines vary in design and functionality, targeting specific needs. For instance, shot blasting machines utilize steel shots to remove rust and scale, enhancing surface quality. They are particularly useful for cleaning large pipes efficiently.

Another type is the pressure blasting machine, which employs compressed air. It is suitable for delicate projects. This machine can effectively clean intricate surfaces without causing harmful abrasions. Users often find the pressure settings need adjustment for optimal results.

Rotary blasting machines are also notable. They use centrifugal force to propel abrasives. These machines are effective for high-throughput operations. However, maintenance can be an issue. Proper upkeep is essential to ensure consistent performance. It's common for operators to overlook this aspect, leading to inefficiencies. Each type of blasting machine brings unique benefits and challenges, influencing their applications in the industry.

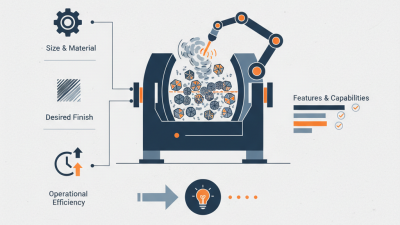

Key Features to Consider in Steel Pipe Blasting Machines

When selecting a steel pipe blasting machine, some key features can enhance surface preparation efficiency. One important factor is the size of the machine. A compact model can fit into tight spaces. Larger machines may handle bigger pipes but require more floor space. Think about your workspace; it can affect your choices. Also, consider the blasting media used. Different types have varying levels of abrasiveness. The choice can impact the pipe’s surface finish.

Another feature to evaluate is the machine’s automation level. Automated machines can reduce labor costs. However, they might require specific training. Finding the right balance between technology and manual operation is crucial. Additionally, dust collection systems are vital for a cleaner environment. They minimize airborne particles, ensuring safer working conditions. The effectiveness of this system can directly influence worker health and productivity.

Pay attention to machine maintenance features as well. Regular upkeep is necessary but often overlooked. Easy access to key components can simplify this process. A poorly maintained machine can lead to inconsistent results. Investing in a model that provides clear maintenance guidelines can save time and frustration in the long run.

Top Steel Pipe Blasting Machine Types for Efficient Surface Preparation

| Machine Type |

Blast Media |

Cleaning Efficiency |

Dust Control |

Maintenance Frequency |

| Centrifugal Blast Machine |

Steel shot |

High |

Excellent |

Monthly |

| Shot Blasting Machine |

Alumina |

Medium |

Good |

Quarterly |

| Suction Blast Machine |

Steel grit |

High |

Very Good |

Biannually |

| Air Blast Machine |

Sand |

Medium |

Moderate |

Monthly |

| Wheel Blast Machine |

Ceramic media |

High |

Excellent |

Annually |

Comparative Analysis of Popular Steel Pipe Blasting Machine Models

When it comes to surface preparation for steel pipes, the choice of blasting machine plays a crucial role. Various models exist, each designed to meet specific needs. A recent industry report shows that 70% of professionals prefer automatic machines for their efficiency. These models significantly reduce labor costs while improving consistency in surface quality.

One popular type is the hook-type blasting machine. It allows for effective cleaning and coating preparation. Its capacity to process multiple pipes in a single cycle makes it an attractive option. Another effective choice is the tumble blast machine. This model provides thorough cleaning due to its rolling motion, which exposes all angles of the pipe. Recent trends indicate that such systems can increase productivity by as much as 50%.

Tips: Consider pipe size and material when choosing a blasting machine. Ensure the model you select is compatible with your operational demands. Evaluate how machine capabilities align with your project requirements. Remember, not all models fit every task perfectly. Researching and comparing will help you avoid costly mistakes. Overall, understanding the unique advantages of each blasting machine is vital for effective surface preparation.

Best Practices for Using Steel Pipe Blasting Machines Effectively

When using steel pipe blasting machines, proper techniques are essential for achieving the best results. Start by ensuring the work area is clear of obstructions. This enhances both safety and efficiency. The type of abrasive material selected plays a crucial role. Different materials can yield varying levels of surface cleanliness. Therefore, testing different abrasives can be useful for specific applications.

Monitor the blasting pressure. Too high can cause damage, while too low may not clean effectively. Regular maintenance of the machine is vital. Clogs and wear can lead to inconsistent performance. Operators should also receive adequate training. Understanding the machine’s settings can prevent common issues.

It's important to reflect on your blasting process occasionally. Are you achieving the desired results? If not, analyze your methods and be open to adjustments. Sometimes a small change can make a big difference in efficiency. Proper documentation of the blasting process can help identify areas for improvement.

Top Steel Pipe Blasting Machine Types for Efficient Surface Preparation

Home

Equipment

Vacuum Process Casting Molding Line

Automatic Flaskless Sand Molding Production Line

Sand Preparation Automation Line

Shot Blasting Peening Equipment

Stainless Steel Stripe Shot Blasting Machine

Steel Preservation Line

Roller Conveyor Shot Blasting Machine

Hook Type Shot Blasting Machine

Pass Through Monorail Shot Blasting Machine

Mesh Belt Shot Blasting Machine

Rotary Table Shot Blasting Machine

Trolley Type Shot Blasting Machine

Steel Pipe Shot Blasting Machine

Crawler Type Shot Blasting Machine

Rolling Drum Shot Blasting Machine

Automatic Titling Drum Shot Blasting Machine

Portable Shot Blasting Machine

Abrasive Blast Booth And Spray Paint Booth

Enviromental Dust Removal Equipment

Why Xinke

News Room

Blog

Contact Us