The Ultimate Guide to Understanding Auto Shot Blasting Machine Benefits in Surface Preparation

In today's competitive manufacturing landscape, surface preparation plays a crucial role in ensuring the durability and aesthetic appeal of products. Among the various techniques available, the Auto Shot Blasting Machine has emerged as a leading solution, praised for its efficiency and effectiveness.

According to a report by MarketsandMarkets, the global shot blasting equipment market is projected to reach USD 4.1 billion by 2026, growing at a CAGR of 6.5% from 2021 to 2026. This growth can largely be attributed to the increasing demand for high-quality surface finishes across various industries, including automotive, aerospace, and construction.

The Auto Shot Blasting Machine not only enhances productivity but also significantly reduces labor costs and improves safety standards in the workplace. As manufacturers continue to invest in advanced surface preparation technologies, understanding the myriad benefits of Auto Shot Blasting Machines will be essential for staying ahead in the industry.

Key Advantages of Using Auto Shot Blasting Machines for Surface Preparation

The utilization of auto shot blasting machines significantly enhances surface preparation processes across various industries. According to market projections, the shot blasting machine sector is expected to expand from $1.41 billion in 2025 to $2.22 billion by 2032, marking a CAGR of 6.7%. This growth underscores the increasing recognition of the advantages these machines offer in terms of efficiency and consistency.

One of the key benefits of auto shot blasting machines is their ability to deliver superior surface quality compared to manual methods. The transition from manual techniques to automated processes has led companies to experience remarkable improvements in productivity. For instance, businesses in the aerospace and healthcare sectors are driving demand for abrasive blasting equipment, with market growth anticipated to increase by USD 148.3 million from 2024 to 2028. As industries adapt to advanced technologies, the advantages of using auto shot blasting machines for surface preparation will continue to shape operational efficiencies and product quality.

How Auto Shot Blasting Machines Enhance Surface Quality and Durability

Auto shot blasting machines play a crucial role in surface preparation, significantly enhancing the quality and durability of various materials. These machines utilize high-velocity shots to clean and smooth surfaces, effectively removing contaminants such as rust, paint, and scale. As a result, the treated surfaces exhibit improved adhesion for coatings and paints, leading to a longer-lasting finish. The meticulous surface profile created by shot blasting also contributes to increased durability, making materials more resilient against wear and environmental factors.

Auto shot blasting machines play a crucial role in surface preparation, significantly enhancing the quality and durability of various materials. These machines utilize high-velocity shots to clean and smooth surfaces, effectively removing contaminants such as rust, paint, and scale. As a result, the treated surfaces exhibit improved adhesion for coatings and paints, leading to a longer-lasting finish. The meticulous surface profile created by shot blasting also contributes to increased durability, making materials more resilient against wear and environmental factors.

When using auto shot blasting machines, it’s essential to consider the type of abrasive material being employed, as this can impact both surface quality and efficiency. For instance, choosing steel shots for tougher surfaces and softer abrasives for delicate materials can optimize results. Additionally, maintaining optimal machine settings such as speed and angle can further enhance performance—ensuring even coverage and preventing damage to the substrate.

Tip: Always conduct a small test blast on a sample piece to gauge the effectiveness and potential effects of the abrasive on the material before proceeding with the full-scale project. Doing so will help you adjust your approach based on the characteristics of the surface being prepared.

Comparing Auto Shot Blasting with Traditional Surface Preparation Methods

When it comes to surface preparation, the choice between auto shot blasting and traditional methods can significantly impact project efficiency and overall results. Traditional surface preparation techniques, such as hand sanding or chemical stripping, often consume more time and labor, leading to increased costs and productivity challenges. According to a report by the Industrial Manufacturing Association, traditional methods can increase project timelines by up to 30%, causing delays in critical operations.

In contrast, auto shot blasting machines streamline the surface preparation process by utilizing high-velocity steel shots to remove contaminants quickly and efficiently. Studies show that auto shot blasting can reduce surface preparation time by as much as 50% compared to manual methods. Furthermore, these machines ensure consistent results with minimal operator intervention, reducing human error and enhancing the quality of the finished surface. A market analysis by TechNavio highlights that organizations adopting automated shot blasting solutions have reported improvements in surface cleanliness levels upwards of 90%, translating to better paint adhesion and longer-lasting coatings.

By integrating auto shot blasting into their operations, businesses not only optimize their workflow but also enhance the durability and performance of the treated surfaces, reinforcing the distinct advantages of automation over traditional techniques in surface preparation.

The Benefits of Auto Shot Blasting in Surface Preparation Compared to Traditional Methods

Understanding the Cost-Efficiency of Auto Shot Blasting in Industrial Applications

The shot blasting machine industry is witnessing robust growth, with projections indicating an increase from $1.41 billion in 2025 to $2.22 billion by 2032 at a compound annual growth rate (CAGR) of 6.7%. This uptick reflects a growing recognition of the cost-efficiency and effectiveness of auto shot blasting in various industrial applications. Industries involved in steel production, which dominates 57.1% of the coating pretreatment market, are turning to these machines for their ability to enhance surface preparation and reduce overall operational costs.

In the building and construction sector, which commands a 38.9% market share, the demand for reliable and efficient surface preparation solutions is critical. The introduction of versatile machines that offer flexibility and economical operation, even at lower production volumes, underscores the industry's commitment to innovation and cost-effectiveness. Furthermore, the emergence of wet blasting technologies provides additional cost-effective solutions for post-processing demands in industries like direct metal laser sintering (DMLS) and selective laser sintering (SLS), streamlining operations while ensuring quality surface finishing that adheres to safety regulations.

Choosing the Right Auto Shot Blasting Machine for Your Specific Needs

Choosing the right auto shot blasting machine is crucial for optimizing surface preparation in various industrial applications. With the shot blasting machine market projected to grow significantly in the coming years, businesses must assess their specific needs before making a purchase. Factors to consider include the type of materials to be processed, the scale of operations, and the desired finish quality. Selecting a machine that aligns with these requirements can lead to increased efficiency and notable cost savings.

Recent advancements in automation, such as the fully automatic shot blasting systems, have transformed the operational landscape. These innovations not only reduce labor requirements but also enhance precision and consistency in surface treatment processes. When evaluating different options, companies should weigh both the technological capabilities and their operational footprints, ensuring that any chosen solution is future-proof and scalable. By carefully assessing these elements, businesses can make informed decisions that support their growth and operational effectiveness.

Home

Equipment

Vacuum Process Casting Molding Line

Automatic Flaskless Sand Molding Production Line

Sand Preparation Automation Line

Shot Blasting Peening Equipment

Stainless Steel Stripe Shot Blasting Machine

Steel Preservation Line

Roller Conveyor Shot Blasting Machine

Hook Type Shot Blasting Machine

Pass Through Monorail Shot Blasting Machine

Mesh Belt Shot Blasting Machine

Rotary Table Shot Blasting Machine

Trolley Type Shot Blasting Machine

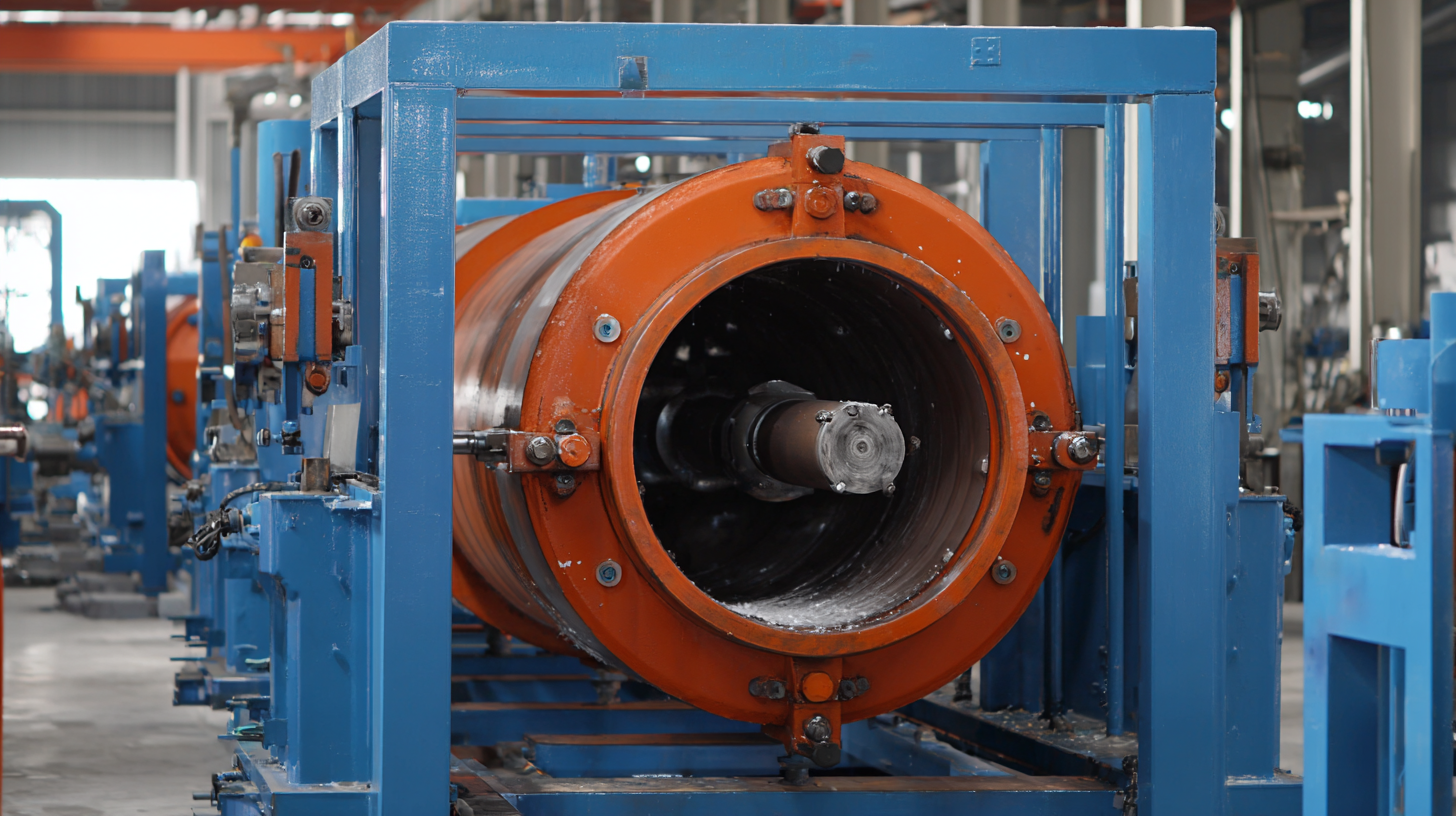

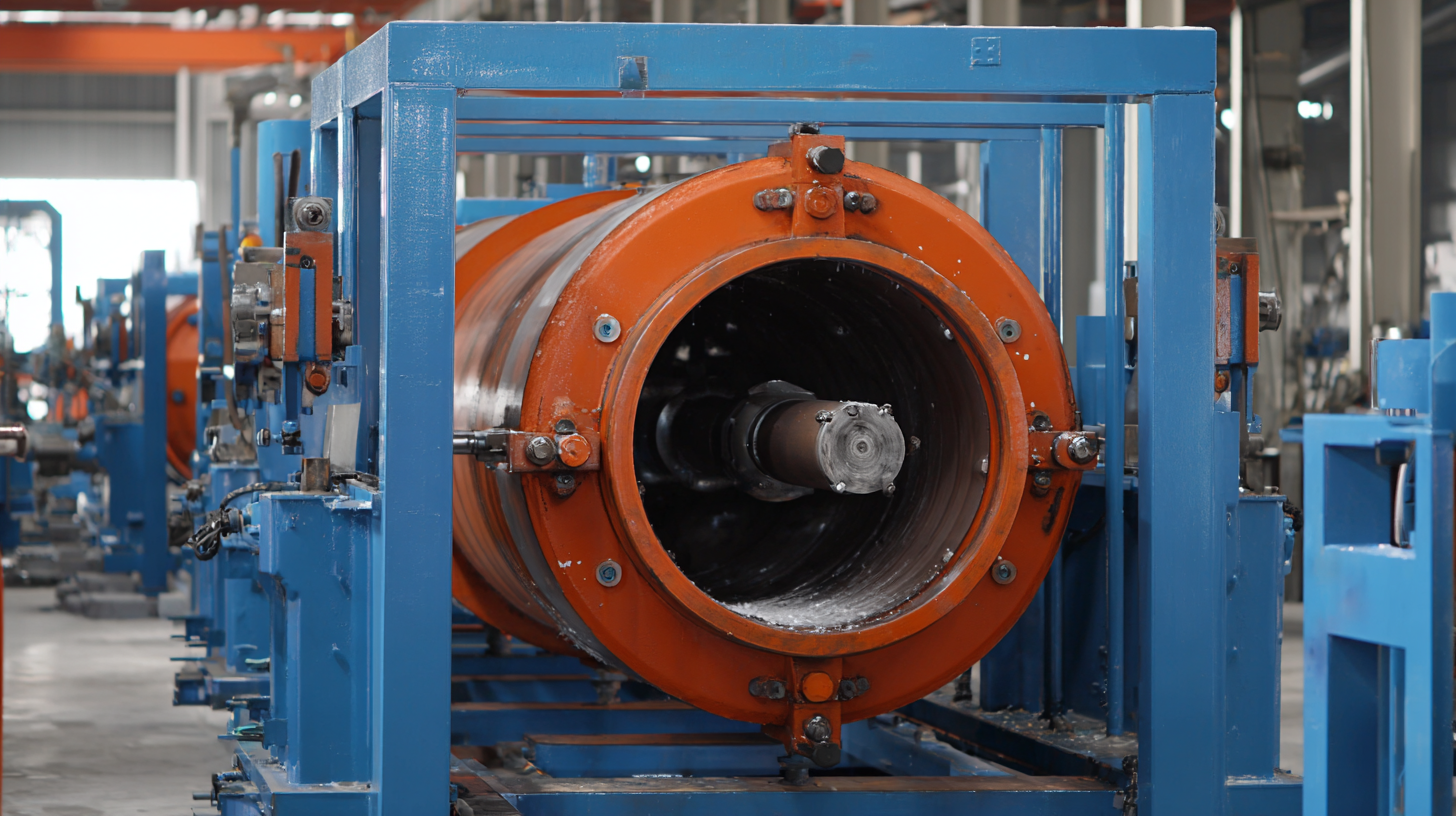

Steel Pipe Shot Blasting Machine

Crawler Type Shot Blasting Machine

Rolling Drum Shot Blasting Machine

Automatic Titling Drum Shot Blasting Machine

Portable Shot Blasting Machine

Abrasive Blast Booth And Spray Paint Booth

Enviromental Dust Removal Equipment

Why Xinke

News Room

Blog

Contact Us

Auto shot blasting machines play a crucial role in

Auto shot blasting machines play a crucial role in