Advantages of the hook shot blasting machine

The hook-type Shot Blasting Machine plays a crucial role in metal surface treatment, particularly for cleaning and rust removal. Its efficiency and effectiveness set it apart from traditional methods, making it a popular choice across various industries. This industrial shot blasting machine operates using mechanical action, effectively removing surface oxides and rust from metal components. This process not only cleans the surface but also enhances its roughness, which is essential for improving coating adhesion and ensuring a durable finish.

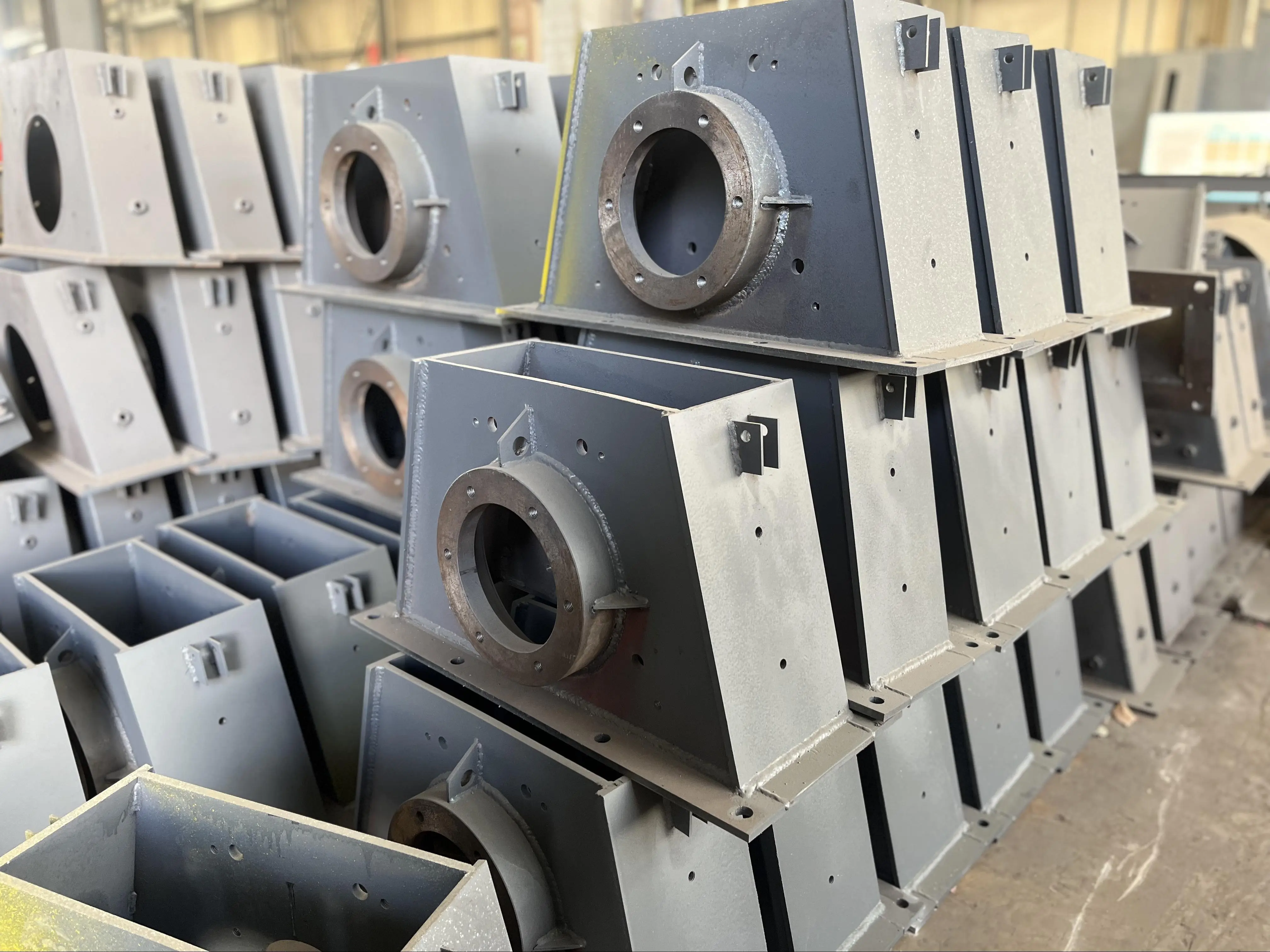

One of the standout features of the hook type shot blasting machine is its versatility. It can accommodate a wide range of metal workpieces, including complex shapes like alloy wheels, regardless of their dimensions. The alloy wheel shot blasting machine exemplifies this flexibility, making it a significant advantage over high-pressure water washing and other rust removal techniques, which often face limitations based on the size and shape of the items being treated. The ability to handle diverse workpieces makes the shot blasting machine for cleaning metal an indispensable tool in industrial applications, where various components require effective surface preparation.

When considering processing efficiency, the industrial shot blasting machine excels in rapidly treating large surface areas. This speed is vital in fast-paced production environments, allowing manufacturers to meet tight deadlines without compromising quality. In comparison, methods like high-pressure water washing tend to be less effective, particularly on heavily rusted surfaces, resulting in longer processing times and potential delays in production schedules, which can be detrimental to overall operational efficiency.

Labor efficiency is another critical advantage of the hook shot blasting machine. With high levels of automation, this machine significantly reduces labor costs and minimizes the physical strain on operators. Unlike manual rust removal techniques, which rely heavily on the skill of the operator, the automated processes of shot blasting provide consistent results. This ensures that each workpiece receives thorough and uniform treatment, which is essential for maintaining high quality in metal finishing and avoiding inconsistencies that could arise from manual labor.

Moreover, the abrasive recovery system integrated into the wheel shot blasting machine enhances operational efficiency by minimizing material waste. This feature not only helps maintain the quality of the blasting process but also lowers overall operating costs. Traditional sandblasting equipment often suffers from high abrasive loss, which can make it less economical over time. In contrast, modern vertical shot blasting machines are designed to be more cost-effective, focusing on optimizing abrasive usage while also prioritizing noise and dust control. This significantly improves the working environment for operators, promoting safety and comfort during operation.

Vertical shot blasting machines and wheel shot blasting machines also share similar benefits, particularly in terms of efficiency and effectiveness for specific applications. These machines are engineered to optimize performance for various metal cleaning tasks, further supporting the need for robust surface preparation in manufacturing processes. Their design allows them to tackle specialized cleaning requirements, making them valuable assets in any production line.

In summary, the hook type shot blasting machine, along with other variants such as the wheel shot blasting machine and vertical shot blasting machine, is essential in the realm of metal surface treatment. Its combination of high efficiency, versatility, and cost-effectiveness positions it as a leading solution for industrial cleaning needs. As companies strive for improved production standards and greater environmental responsibility, investing in advanced shot blasting technology remains a strategic choice that can yield significant long-term benefits, ensuring not only enhanced productivity but also superior product quality.