Application advantages of stainless steel belt

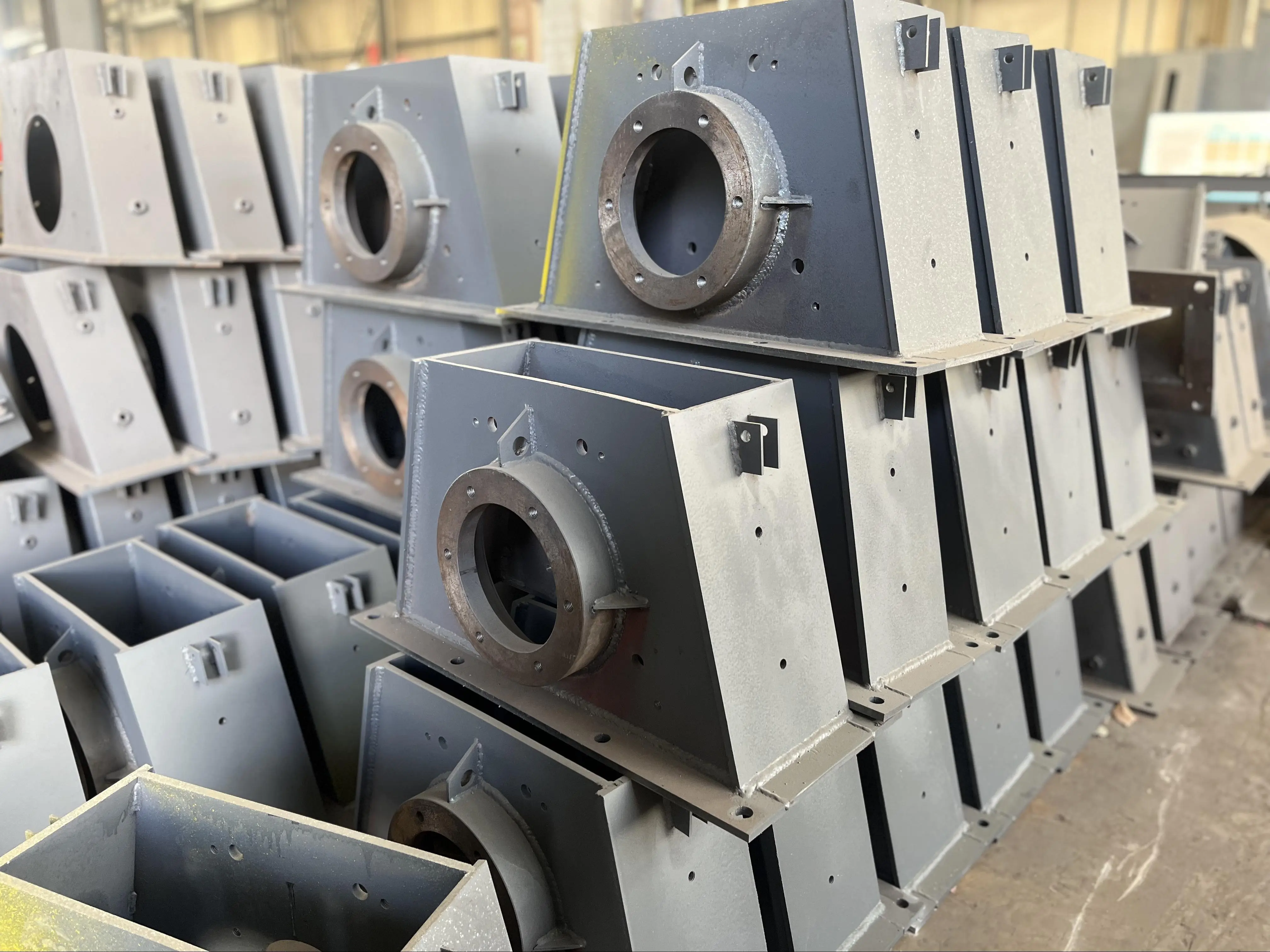

Stainless Steel Belt Shot Blasting Machine The main component are shot blasting system, blowing system, abrasive recycling & separation system, and dust collection and filtration system.

The shot blasting system is one of the main system. Through the blasting flow formed by high speed rotation of impeller driven by motor to remove iron oxide from strip surface. Exact and automatic adjustment of all blast wheels for a new strip programme permits full exploitation of the blast stream in the entire width range and results in high descaling performance and quality.Among The blowing chamber in the blowing system is connected to the shot blasting chamber, a compressed air blower removes abrasive residue from the upper side of the strip after each blasting process.Abrasive recovery and separation system The shot blasting machine is a recycling system, the newly added abrasive enter the lower spiral from the feeding hopper. The lower screw transfers the new abrasive to the upper screw through the bucket elevator. After entering the separator, it is redistributed to each turbine.Dust collection and filtration system:A large amount of dust and tiny pellets will be produced in the whole shot blasting process. Shot blasting chamber, air blowing chamber and separators are connected with dust collection system. To reduce the wear of pellets on the shot blasting machine.

Stainless Steel Belt Shot Blasting Machine is widely used in the production process of stainless steel belt,Especially in the cold rolling process,By shot blasting,It can ensure the surface roughness and thickness accuracy of cold-rolled stainless steel strip,Suitable for surface pretreatment of Stainless Steel sheet, strip and other metal materials,in addition,The equipment is also suitable for removing the oxide skin and burr on the surface of nonferrous metals such as aluminum alloy and copper alloy to achieve a comprehensive effect.