Characteristics of Steel plate pretreatment line

The pretreatment of steel can improve the corrosion resistance of mechanical products and metal components, improve the fatigue resistance of steel plate and extend its service life. At the same time, it can also optimize the production state of the steel surface process, which is conducive to CNC cutting machine and precision blanking. In addition, because the shape of the steel before processing is more regular, which is conducive to mechanical rust removal and automatic painting, the use of steel pretreatment can greatly improve the efficiency of the cleaning work, reduce the labor intensity of the cleaning work and pollution to the environment.

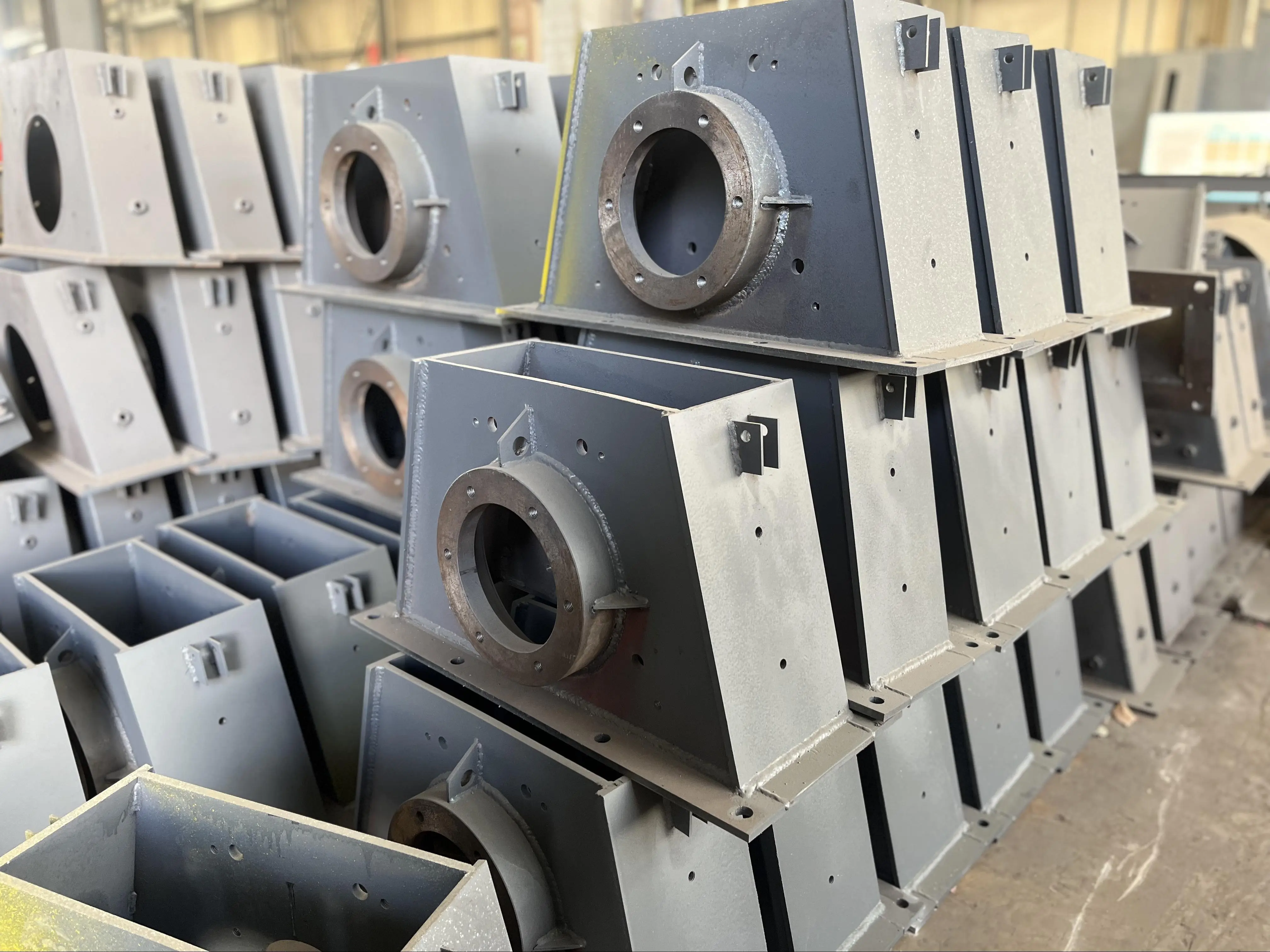

The Steel pretreatment line adopts PLC control, the whole machine is equipped with automatic detection device, belongs to the international advanced level of large complete sets of equipment, mainly by the roller conveying system, Shot Blasting Machine, automatic painting system, drying room, dust removal system, paint fog filter system and electronic control system, and can be extended automatic loading and unloading system and preheating chamber.

Due to the complex working process of the steel plate pretreatment line, it is basically impossible to manually operate, so the automatic control is a necessary condition for the steel plate pretreatment line. Generally use PLC programmable controller, the most basic is to realize the automatic opening of the equipment to the ready work state, the equipment will automatically collect data after loading, and then accurately judge the shot blasting switch time, control the spray paint width, etc. Audible or optical alarm can be used when the equipment is faulty until the equipment is automatically shut down.

In addition, the high-end equipment may use touch screen, computer monitoring and other systems. Electronic control system is a very important part of the steel plate pretreatment line, a better electronic control system can maximize the productivity of the equipment, extend the service life of the equipment, save electricity, paint, heat and labor consumption.