China Leading Hook Shot Blasting Machine- Qingdao Xinke Machinery

Qingdao Xinke Machinery is at the vanguard of shot blasting technological revolution, and the company is providing customized Shot Blasting Machines to meet the unique needs of each customer. Qingdao Xinke has positioned itself as a key player in the shot blasting machine market with a focus on innovation and flexibility. Their commitment to customization enables foundries to improve operational efficiency, ensuring that each machine is designed to fit seamlessly into existing workflows while maximizing productivity.

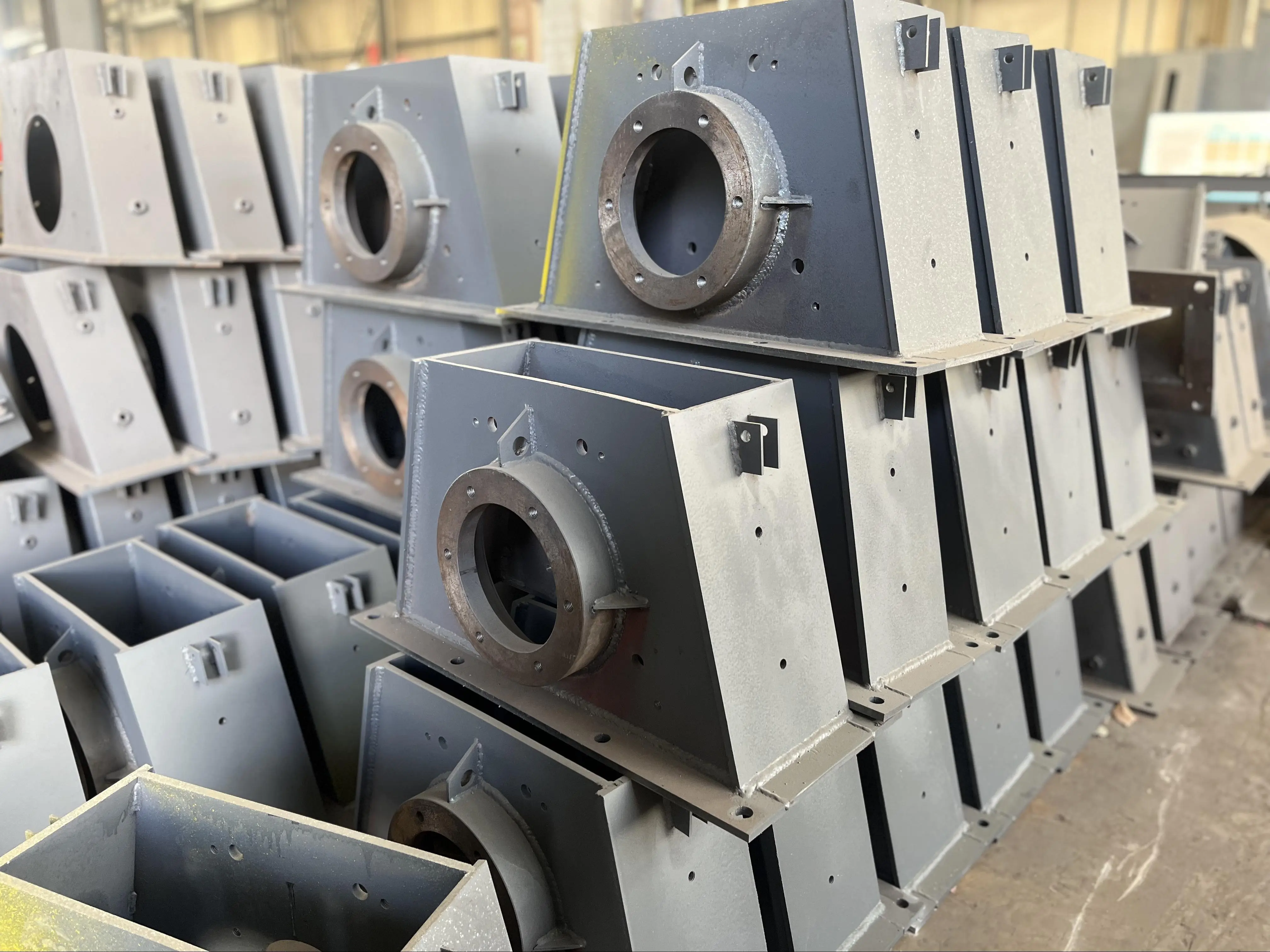

One of the best in Qingdao Xinke's product line is the hook-type shot blasting machine, which is the standard model in the shot blasting machine category. The working cylinder diameter of this sturdy machine ranges from 900 to 1300 mm, and the height can be adjusted between 1300 and 3500 mm. This shot blasting machine can accommodate 2-7 blasting heads and has a maximum load capacity of up to 10,000 kg. With excellent productivity and flexibility, this model is an ideal choice for foundries that want to enhance cleaning and strengthening processes.

Qingdao Xinke's hook-type shot blasting machines are unique in their unparalleled customization options. Every parameter of the machine can be customized to specific operational requirements, allowing foundries to optimize their shot blasting processes. Whether adjusting size, capacity or functionality, Qingdao Xinke ensures that each shot blasting machine is able to provide maximum performance and efficiency. This level of customization not only improves the efficiency of the shot blasting process, but also helps to significantly save costs and reduce turnaround time.

In the ever-evolving landscape of foundry technology, Xinke Machinery stand out as industry leaders, offering a comprehensive suite of solutions that encompass every aspect of the foundry process. From sand preparation, molding, cooling, vibration finishing and shot blasting, company providing a complete foundry experience, ensuring that every step of the manufacturing process is optimized for performance and quality.