How to solve the problem that the hook shot blasting machine not feeding?

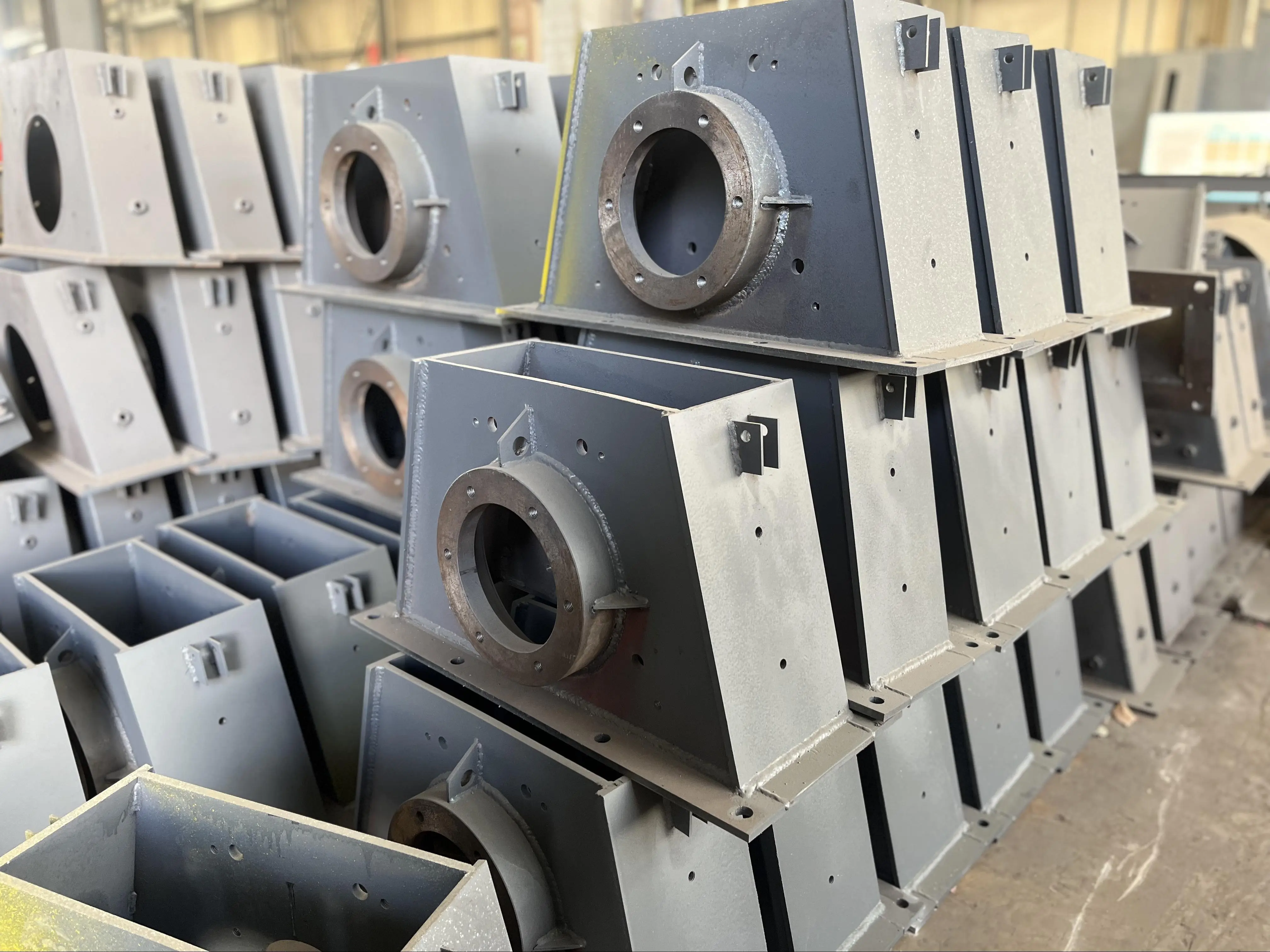

The hook Shot Blasting Machine chamber is welded with steel plates, and several shot blasting wheels are arranged on one side of the chamber. The interior of the shot blasting chamber is equipped with laminated protection plate, and the inner layer is welded into the outer shell of the chamber. The outer building block structure of protection plate is fixed with special high chromium hardening nut, which is durable and easy to maintain.

In order to facilitate maintenance, an access door is provided on the outside of the main chamber to observation of the wear condition of the indoor protection plate and shot blasting wheels frequently. The closing point is selected with the convenient manual screw locking nuts, which greatly reduces many tedious processes for maintenance operators. A guard plate is arranged at the bottom of the shot blasting chamber, and the lower end of the guard plate is serrated for passing through the dropped projectile, thus ensuring the service life of the spiral. In the upper part of the shot blasting chamber, it can remove the dust caused by shot blasting in time, optimize the working environment of the bearing of the recovery system, and extend the operating life of components. At the top opening of the shot blasting chamber, there is a labyrinth sealing slot and a rubber and brush sealing curtain with exquisite structure to root out the projectile and rebound to the outside of the chamber.

In the daily use of the hook shot blasting machine, if the bucket elevator reducer of shot blasting machine is running normally, but it is not loaded, and causing the longitudinal and transverse screw of the shot blasting machine to get stuck, resulting in damage to the machine spare parts. How do we deal with it?

By adjusting the tightness of the lifting belt to change the speed of the lifting bucket.