How to use advanced stainless steel belt shot blasting machine to improve metal surface quality

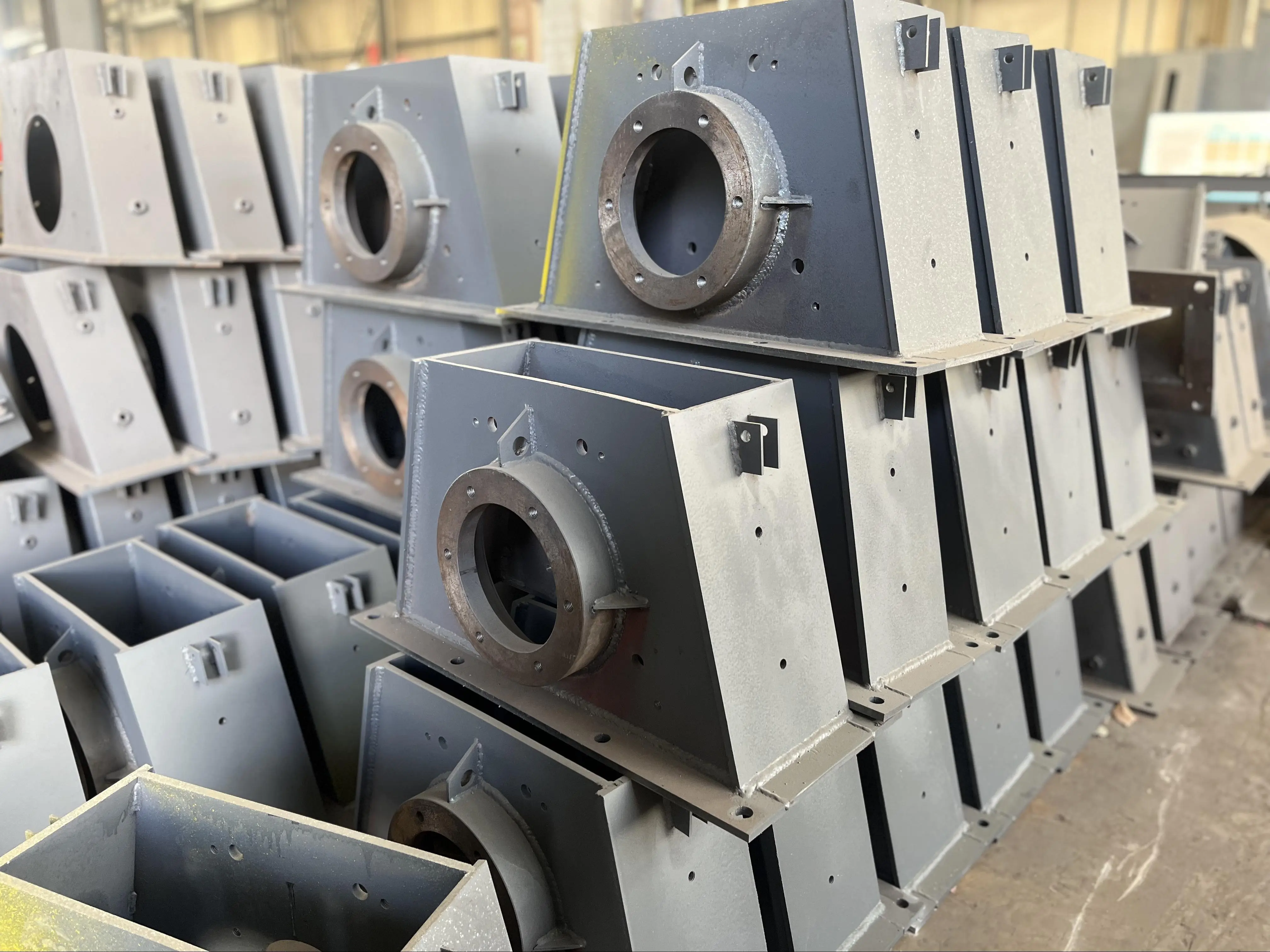

Stainless steel Shot Blasting Machines are essential tools in industrial surface preparation, designed to clean, strengthen, or polish metal surfaces. These machines, such as the Stainless Steel Shot Blast Machine or Steel Strip Shot Blasting Machines, use a process called shot blasting to achieve a high-quality finish. Here’s a breakdown of how they work:

- Loading the Material: The stainless steel strips, coils, or sheets are fed into the machine through an automated conveyor system. For example, in a Steel Coil Shot Blasting Machine, the coil is unwound and passed through the blasting chamber.

- Blasting Process: Inside the chamber, high-velocity abrasive media (such as steel grit or ceramic beads) is propelled onto the surface of the stainless steel. This is done using a high-speed rotating wheel or compressed air in Industrial Shot Blasting Machines. The impact of the abrasive media removes rust, scale, oxides, and other contaminants, leaving a clean and uniform surface.

- Surface Treatment: The blasting process not only cleans but also enhances the surface by creating a textured profile. This improves adhesion for coatings or paints, making it ideal for applications like Stainless Steel Annealing Pickling Lines.

- Media Separation and Recycling: After blasting, the used abrasive media and debris are collected and separated. Advanced systems, like the HB Steel Belt Rust Blasting Equipment, include efficient media recovery and recycling mechanisms to minimize waste and reduce operational costs.

- Final Cleaning and Inspection: The stainless steel strip or coil exits the blasting chamber and undergoes a final cleaning process to remove any residual media. It is then inspected for quality before proceeding to the next stage, such as a Strip Shot Blasting Machine Pickling Line.

Stainless steel shot blasting machines, including Steel Belt Shot Blasting for Rapid Cleaning and Rust Descaling Machines, are widely used in industries like automotive, aerospace, and construction. They ensure superior surface preparation, enhancing the durability and performance of stainless steel products.

By combining precision, efficiency, and advanced technology, these machines deliver consistent and reliable results, making them indispensable in modern manufacturing processes.