Introduction of Xinke Horizontal Parting Automatic Molding Machine

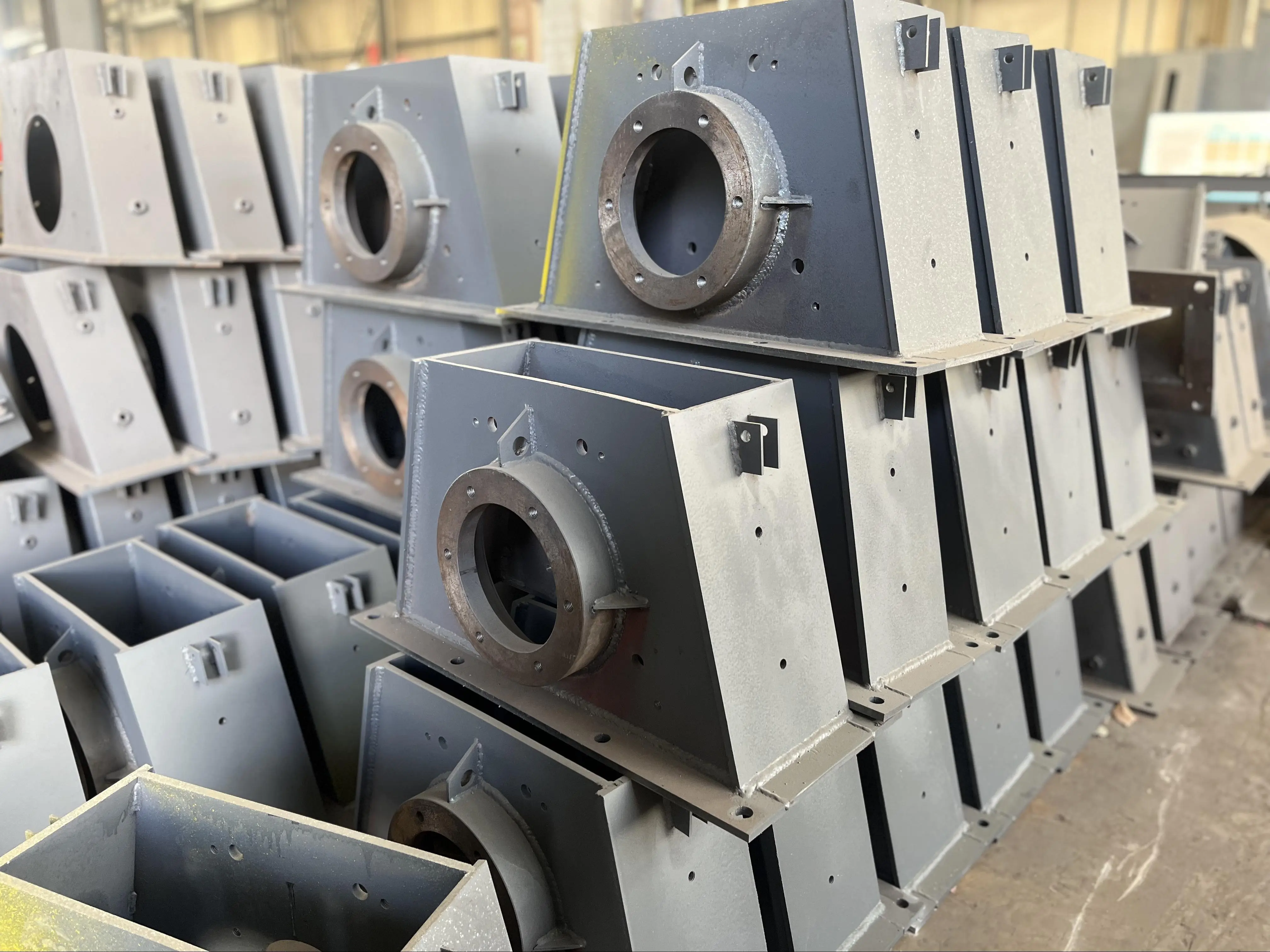

Qingdao Xinke Machinery Technology Co., Ltd has recently introduced the horizontal parting flaskless Automatic Molding Machine, which has garnered attention in the industry.

This machine is capable of achieving automatic sand injection, compaction, and modeling, making it suitable for a wide range of applications.

One of the key features of the Xinke automatic molding machine is its ability to use a single sand mold to produce multiple castings. This is particularly advantageous for high precision and complex casting molding, as it significantly reduces the need for manual labor and improves overall production efficiency.

The machine is equipped with two independent sand shooting systems, which control the airflow to simultaneously shoot sand from both the upper and lower directions. This innovative method ensures the uniform filling density of the molding sand, leaving no empty corners and addressing the limitations of traditional horizontal shooting methods.

Further more, the machine utilizes multi-stage high-speed extrusion to render the inner cavity of the sand mold smooth, compact, and uniform without any loose sand, resulting in high-quality castings, In terms of operation and maintenance, the automatic molding machine adopts a double-sided aluminum or iron pattern plate for sand modeling. The process of replacing and installing the pattern plate is simple and convenient, requiring only a few screws and taking approximately 15 minutes to complete.

Additionally, the lower sand box can be slid out over a distance of 900mm, facilitating the placing of large and heavy sand cores, For safety and operational efficiency, warning lights can be installed in the operating area to alert operators of any interference, prompting the machine to stop working. There is also an alarm prompt system to notify users of any abnormalities.

The machine also offers flexibility in adjusting the location of sand shooting ports and pouring gates to accommodate the structure of the casting. Precision is ensured through the design of positioning pins, which provide two times positioning of the sand mold during closure to prevent misalignment.

After modeling, the sand mold is pushed out by a servo electric cylinder.

The control system of the Xinke molding machine is highly intelligent and automatic, with the option to select Siemens or Omron PLC control and a 10-inch touch screen for digital control. Operators can easily input parameters such as pressure, sand mold height, molding speed, and sand shooting time to customize the machine's operation, In terms of components, the machine incorporates Schneider's air switches, leakage protectors, and AC-contactors, as well as Omron DC switching power supply, encoder, relay, thermostat, and more. To reduce noise and energy consumption, the machine utilizes a full-servo duplex hydraulic pump and effectively controls oil temperature.

In addition to the automatic molding machine, the company provides three popular types of solutions to match with automatic molding machines: a reductionist solution with a low investment cost, a long-term solution with an automatic ground track conveyor line, and the most advanced solution with a fully automatic trolley conveyor line and manipulator. These solutions cater to different production needs and offer varying levels of automation and productivity.

Qingdao Xinke Machinery Technology Co., Ltd offers comprehensive support for the encompassing production line layout design, installation guidance, on site commissioning, operation training, and after-sales services.

The company has established itself as a fully integrated industrial entity, encompassing scientific research, development, production, and business operations, with a focus on high-end surface treatment equipment, sand treatment equipment, and casting molding equipment.

Overall, Xinke horizontal parting flaskless automatic molding machine represents a significant advancement in the field of casting molding equipment, offering a range of innovative features and capabilities to meet the evolving needs of the industry.