The main application of hook type shot blasting machine

The hook type Shot Blasting Machine is a widely utilized piece of equipment in the field of metal surface treatment. Its primary function is to clean the surfaces of various workpieces by removing oxide scale, rust, and other contaminants through the application of shot blasting technology. This process is crucial for enhancing the durability and aesthetic appeal of metal products and is employed across numerous industries, including automotive, shipbuilding, aerospace, and machinery manufacturing.

The working principle of a hook type shot blasting machine involves the use of a high-speed rotating shot blasting wheel. This wheel propels abrasive media, typically made of steel shot or aluminum shot, at significant velocities and specific angles toward the surface of the workpiece. The impact of these abrasive particles plays a vital role in effectively removing contaminants and creating a rough surface texture. This roughness significantly improves the adhesion properties of subsequent coatings and paints, which is essential for achieving high-quality finishes.

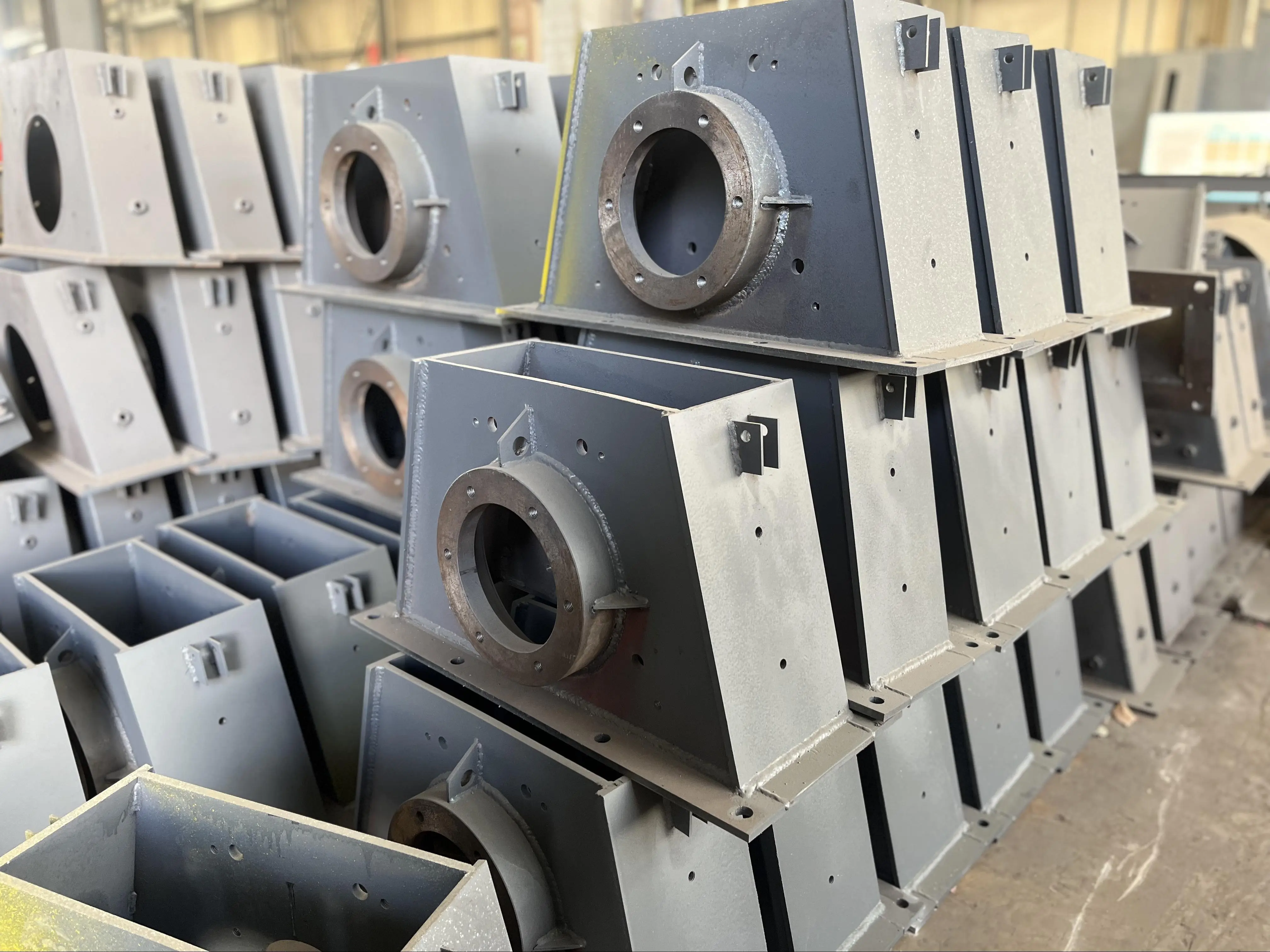

One of the key advantages of the hook type design is its ability to allow workpieces to rotate freely during the blasting process. This rotation ensures that the abrasive media can reach all areas of the workpiece uniformly, thus guaranteeing an even treatment throughout the entire surface. The shot blasting chamber of the machine is constructed from highly wear-resistant materials designed to withstand the intense impacts from the abrasive media while maintaining excellent sealing properties. This durability contributes to the overall longevity of the machine.

In addition to its robust construction, the hook type shot blasting machine is equipped with an efficient recovery system. This system is responsible for reclaiming unused abrasive media, ensuring that resources are not wasted and reducing the overall operating costs for the user. The efficiency of this recycling system is an important feature, especially in high-volume production environments where cost-effectiveness is a priority.

As a leading manufacturer of industrial shot blasting machines, Qingdao Xinke Company offers a range of products tailored to meet the diverse needs of its customers. The hook type shot blasting machine comes equipped with an advanced programmable logic controller (PLC), which allows operators to manage and adjust the shot blasting parameters with precision. This capability includes adjusting the blasting speed and flow of abrasive media based on the specific requirements of different workpieces. Furthermore, the machine is designed with multiple safety features that protect both the operators and the equipment, ensuring a safe working environment.

The efficiency of the hook type shot blasting machine is a significant factor in its popularity among manufacturers. It enables the treatment of large surface areas in a relatively short amount of time, which greatly enhances overall production efficiency. The machine is also optimized to achieve higher shot blasting speeds while providing consistent and uniform treatment results. The design also facilitates the recycling of abrasive media, reducing waste and promoting environmentally friendly practices in manufacturing processes.

In conclusion, the role of shot blasting machines for cleaning metal surfaces is becoming increasingly important as industrial technology continues to advance. Qingdao Xinke Company is committed to delivering high-quality shot blasting equipment along with superior service. We believe that the hook type shot blasting machine will continue to serve as a reliable solution for surface treatment across various industries, helping businesses improve their production efficiency and enhance product quality.