The versatility of catenary shot blasting machine in industrial applications

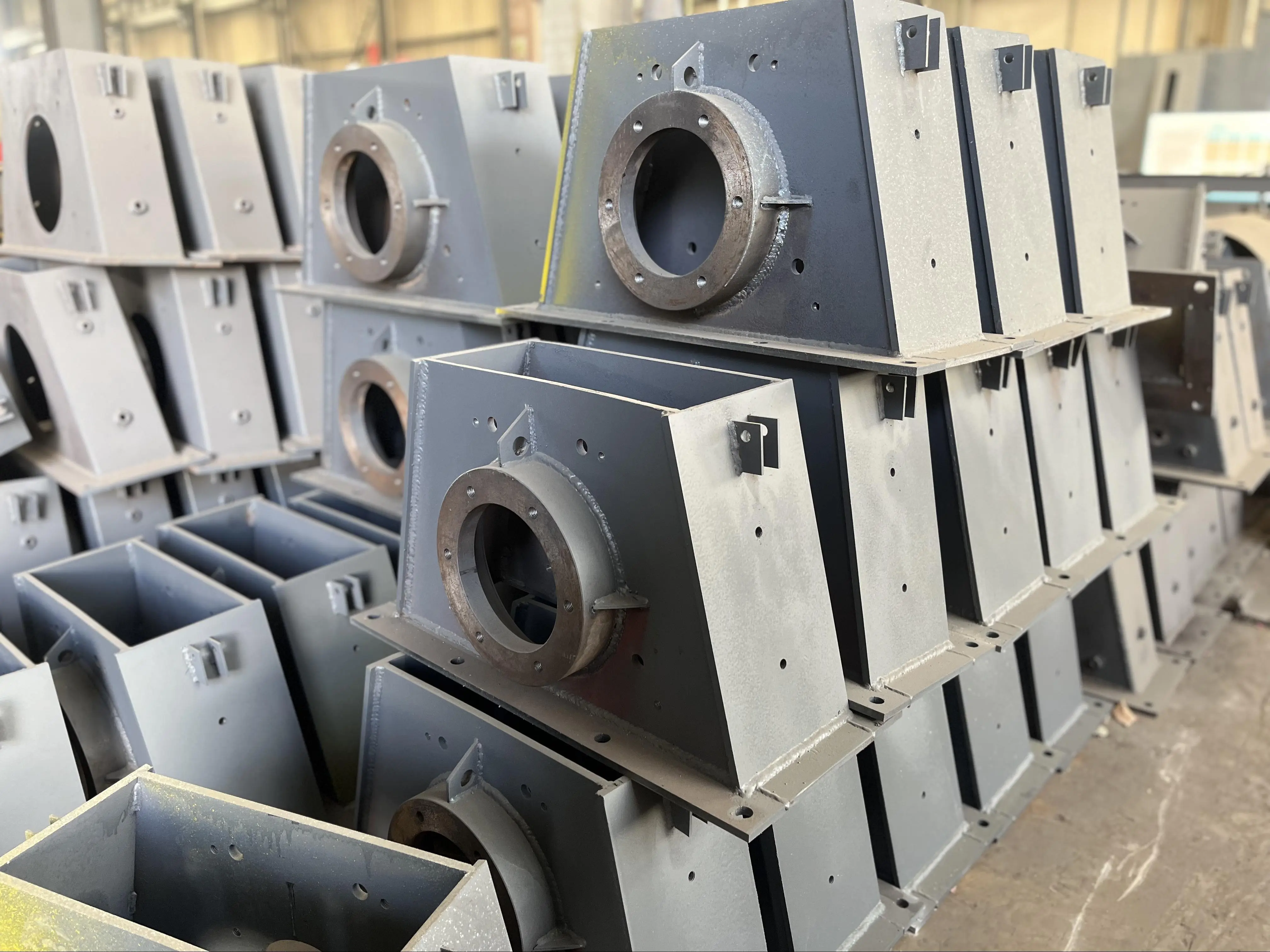

The pendant chain Shot Blasting Machine is specifically designed to handle large, complex, and heavy components, such as engine blocks, transmission cases, and other foundry castings. By suspending the parts on a chain conveyor, the machine ensures uniform exposure to high velocity abrasive media, effectively removing sand, scale, and oxides. The result is a clean, smooth surface ready for further processing, such as painting or coating. Its adaptability makes it a preferred choice for shot blasting machine for foundry castings, ensuring consistent quality and reduced downtime.

For industries requiring high-throughput cleaning of metal parts, the catenary shot blasting machine stands out. This system is particularly effective for cleaning structural steel components, automotive parts, and large fabricated assemblies. The catenary design allows parts to be transported through the blasting chamber in a continuous loop, ensuring thorough and efficient cleaning. Its robust construction and ability to handle heavy loads make it a go-to solution for shot blasting machine for cleaning metal in high-volume production environments.When it comes to cleaning parts with complex geometries, the spinner hanger shot blasting machine excels.This machine is equipped with rotating hangers that ensure all surfaces of the workpiece are exposed to the abrasive stream. It is particularly effective for components like gears, impellers, and turbine blades, where precision cleaning is paramount. The spinner hanger shot sand blasting machine variant further enhances its capabilities by incorporating sand as the abrasive medium, making it suitable for applications requiring a finer finish.

The versatility of these shot blasting machines extends beyond cleaning. They play a crucial role in surface preparation, enhancing the adhesion of coatings and extending the lifespan of metal components. For instance, in the automotive industry, shot blasting machine for cleaning metal ensures that parts are free from contaminants before assembly, reducing the risk of failure. Similarly, in the foundry sector, shot blasting machine for foundry castings improves the quality of castings by removing residual sand and scale, ensuring they meet stringent industry standards.

As industries continue to push the boundaries of innovation, the importance of advanced shot blasting technology cannot be overstated. Whether it's the precision of the pendant chain shot blasting machine, the efficiency of the catenary shot blasting machine, or the versatility of the spinner hanger shot blasting machine, these systems are transforming the way metal cleaning and surface preparation are approached.By investing in these cutting-edge solutions, manufacturers can achieve higher productivity, improved product quality, and ultimately, a competitive edge in the global market.