The working principle of turbine shot blasting machine

The turbine Shot Blasting Machine cleaning and strengthening is a cold treatment process, that is, through the motor drive the shot blasting wheel operation will be countless small round called the steel shot media continuously hit the surface of the cleaning part. Each steel shot hits the metal part like a miniature rod hammering the exterior, making small indentations or depressions. To create a depression, the surface of the metal must be stretched, under the surface, the condensed grains attempt to restore the outer surface to its original shape, resulting in a highly condensed hemisphere.

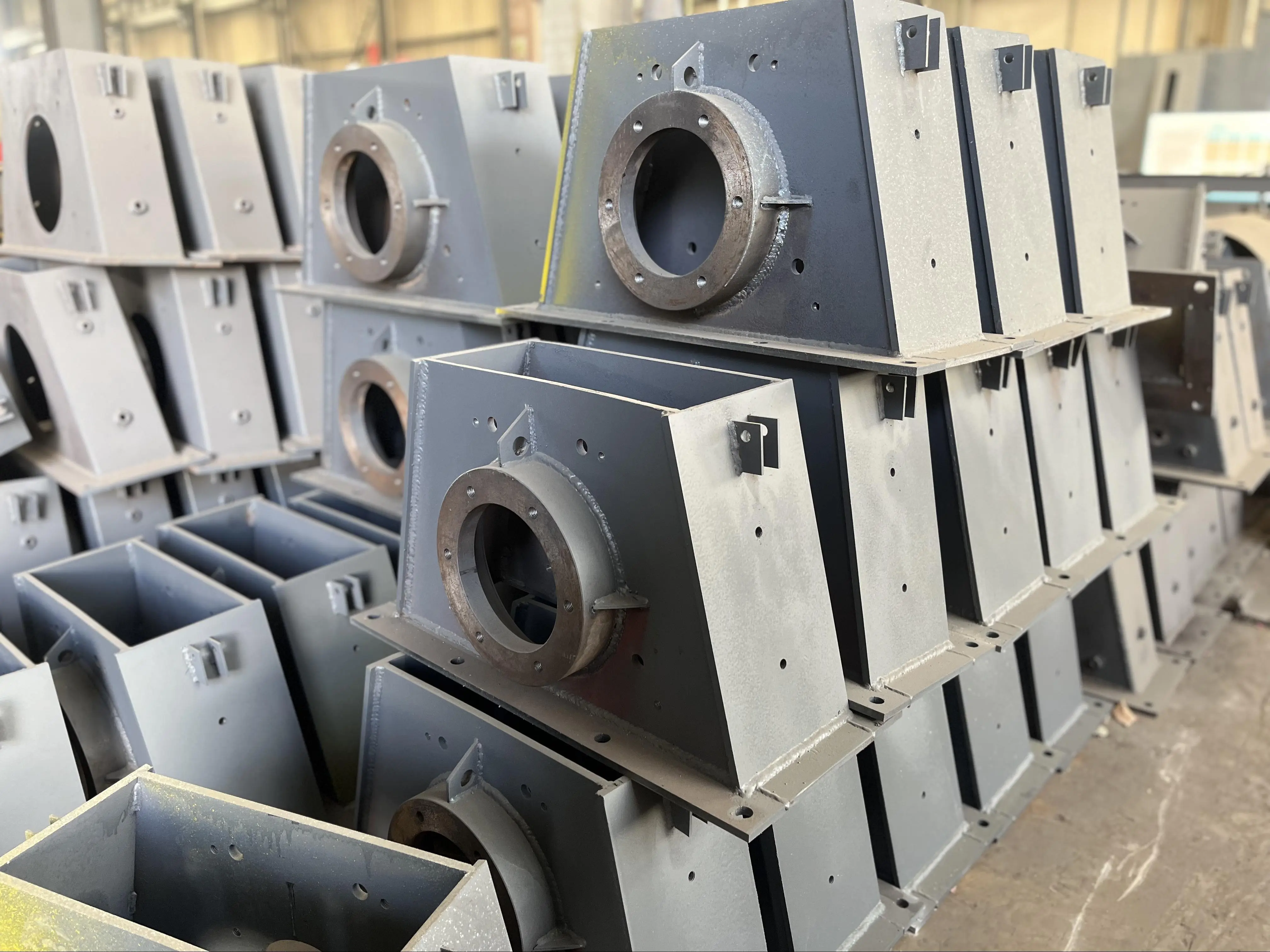

Numerous concave stacks constitute an average residual compressive stress layer, which further improves the marked hardness and fatigue strength of the part, and significantly extends the service life of the part. The appearance of the newly casting is not clean, there will be a local burr and clay sand, and it is necessary to do sand, rust prevention and other disposal in the later period. There are pores on the appearance of local defective products, which leaves a safety hazard for the use of products, so the need to stop the appearance of the casting flaw detection disposal, shot blasting machine is able to meet the above needs.

So after the shot blasting is stopped, what is the principle applied to the non-destructive inspection of the part surface? The casting is transported to the blasting machine chamber by hook, crawler belt or roller conveyor, the part is rotated and rolled in the chamber while shot blasting. A shot blasting wheel with reasonable planning is arranged around the main chamber of the shot blasting machine, which can accelerate the metal abrasive ejection. After the intensive metal abrasive attack, it can effectively clean sand and polish, and at the same time, the casting with defects can be selected, and the porosity will be exposed early to prevent the formation of safety hazards in the later period.