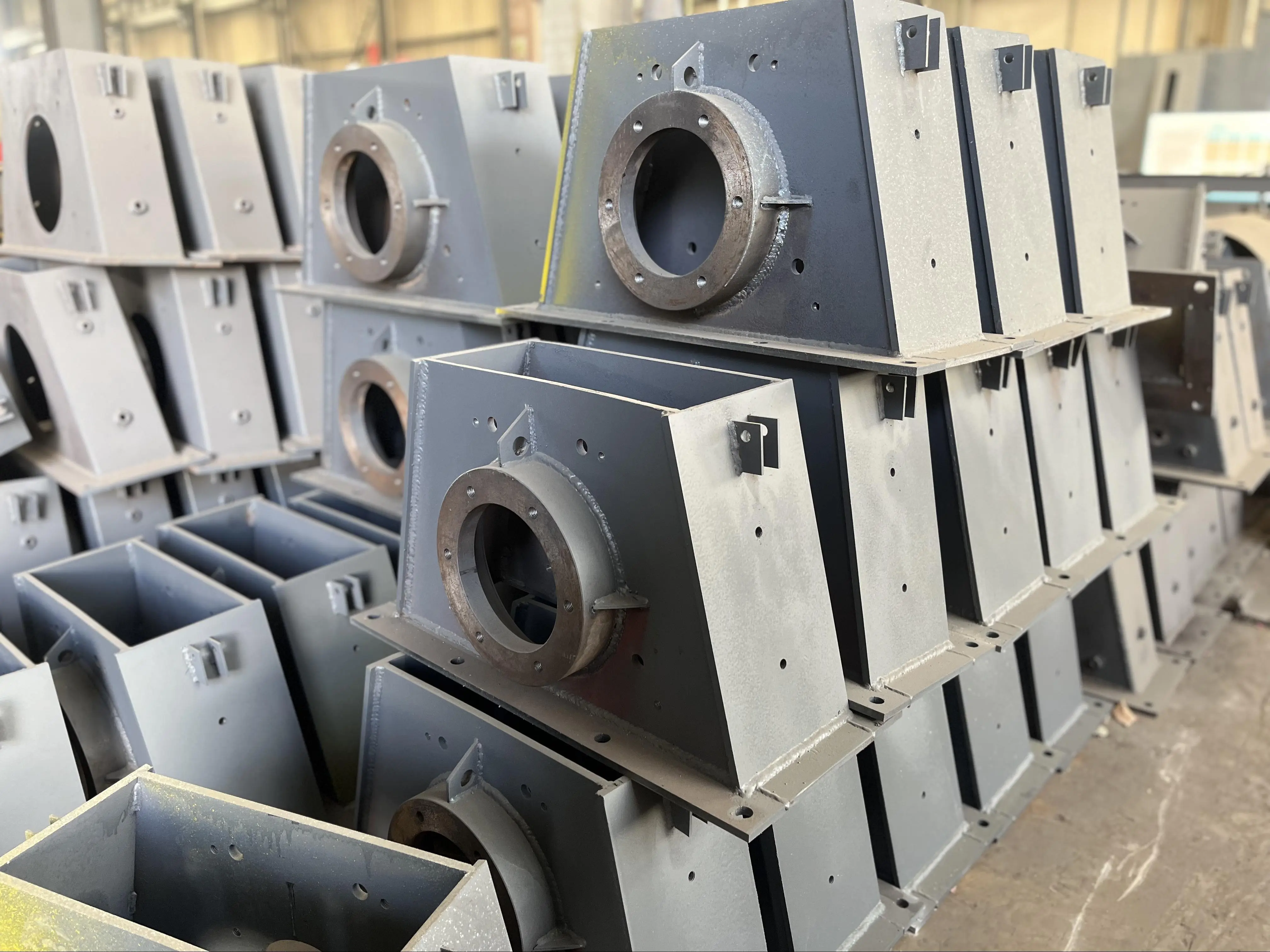

Two kinds of connection methods of shot blasting head

Qingdao Xinke is a leading manufacturer specializing in customized Shot Blasting Machines and sand blasting rooms, leverages world-advanced turbine technology to deliver high-performance solutions. The main product range includes crawler type shot blasting machine, drum shot blasting machine, hook shot blasting machine, and roller conveyor shot blasting machine, the shot blasting wheels can be customized to meet specific operational requirements. The smallest shot blasting wheel starts at 7.5 kW, with options to customize up to 110 kW for more demanding applications, such as high speed shot blasting machine for cleaning stainless steel stripe.

The belt connection is a common connection between the throwing head and the motor. The advantage of this way is that the violent vibration of the throwing head will not be transmitted to the motor, the motor can operate in a relatively stable state, and the splashing steel sand of the throwing head is relatively not easy to cause damage to the motor, so the failure rate of the motor will be reduced. But its disadvantage is that the actual speed of the throwing head can not be accurately monitored. Since the motor and the throwing head are connected through the belt and the belt, the speed of the motor is transmitted to the throwing head through the speed ratio of the belt and the belt disc, so that the tightness of the belt and the wear degree of the belt disc are different, which will cause the loss of the transmission speed. At the same time, each parameter of the inverter is to detect the motor, and it can not directly detect the operation of the throwing head, and the particularity of its work occasion, it can not install the detection switch on the additional throwing head and detect the actual running state of the throwing head. That is to say, only through the motor's operating frequency, speed, current indirect monitoring, there is a certain uncertainty.

The direct connection between the throwing head and the motor is another connection method, and the advantage is that the rotation speed of the motor can be directly transmitted to the throwing head, and the power is small. And can well detect the speed of the throwing head, because the throwing head and the motor are directly connected, the speed of the motor is the speed of the throwing head, and the speed of the motor is very easy to detect. Generally speaking, the motor is operated by the frequency converter, and the operation parameters of the motor are easy to detect on the frequency converter, and the operation of the throwing head can be judged by the operation of the motor to determine whether the operation is normal and whether it meets the process requirements. At the same time, this connection method saves space, and when designing the equipment, only the position of the throwing head needs to be designed, and there is almost no need to reserve the position of the motor. However, this connection method has obvious disadvantages: the blast head vibration is very large when the machine is running, so the vibration of the motor will also follow, such a large vibration will make the motor coil friction, the friction between the wire and the shell, easy to cause insulation damage to the motor coil damage, and the motor shell will also cause different degrees of damage due to long-term vibration, or even fracture.